|

(11) | EP 0 000 101 B1 |

| (12) | EUROPEAN PATENT SPECIFICATION |

|

|

| (54) |

Cuprous oxide containing resin bonded abrasive article and process for manufacturing same Mit einem Kupfer (I)-oxid enthaltenden Harz gebundener Schleifgegenstand und Verfahren zu seiner Herstellung Corps abrasif à liant résineux contenant de l'oxyde cuivreux et son procédé de fabrication |

|

|

|||||||||||||||||||||||

| Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). |

[0001] This invention relates to resin bonded abrasive articles and their method of manufacture and more particularly relates to resin bonded abrasive wheels.

[0002] Resin bonded abrasive articles, particularly resin bonded abrasive grinding wheels, are well known in the art. Such wheels are used for numerous applications including grinding, polishing and cutting. In operation, abrasive wheels are rotated at high speeds which makes it imperative that the wheels have sufficient physical strength and flexibility to withstand the high centrifugal forces generated during rotation and to withstand outside forces applied to the wheels during the grinding, polishing or cutting operation.

[0003] In the prior art, very high speed wheels ; i.e. those made for use at speeds in excess of 3 000 rpm, still occasionally break when they are being used which sometimes causes pieces of the abrasive wheel to fly off the wheel due to centrifugal force.

[0004] It is therefore clear that increasing the physical strength of abrasive wheels to further reduce breaking or cracking of the wheels is highly desirable.

[0005] Many attempts have been made to increase the strength of abrasive wheels with limited success. Such attempts have included using improved and modified resins and as disclosed in U.S. Patents 3,481,723 and 3,528,790 have included the use of modified abrasive grain to achieve improved strength.

[0006] The use of fillers blended with the resin have also been found to increase wheel strength. Additionally, such fillers as disclosed in U.S. Patent2,371,700 comprised certain metals or metal compounds of certain metals of groups IV, V, VI, VII and VIII of the fourth series of the periodic table of elements. An example of such a compound is chromium oxide. Additionally, as disclosed in U.S. Patent 2,070,734, ferric oxide has been known as a suitable filler. Other suitable fillers disclosed in U.S. Patent 3,087,803, include chromium oxide, zirconia and titania. Iron sulfide is disclosed as a suitable filler in U.S. Patent 3,632,320 and trimanganese tetroxide and ferric oxide have been disclosed as suitable fillers in U.S. Patent 3,960,517.

[0007] It has also been recognised in the prior art that certain other metal compounds will act as suitable fillers. U.S. Patent3,820,290 for example, discloses that potassium fluroborate, sodium flu- roaluminate, barium sulfate, iron sulfide and calcium oxide are satisfactory filler compositions. In addition to other filler compositions previously mentioned, U.S. Patent 3,632,320 discloses that cryolite, fluorspar, zincblende, lead chloride and lead sulfide are suitable fillers. U.S. Patent 3,087,803 discloses that silicon dioxide and aluminium oxide may comprise suitable filler compositions. Magnesium oxide is suggested as an appropriate filler composition in U.S. Patents 2,294,239 and 3,208,836. Despite the numerous types of filler compositions tested and utilized in the prior art, such compositions even at the high percentage use level commonly used, do not impart as much strength to the bonded abrasive article, such an abrasive wheel, as is desirable.

[0008] In accordance with the invention there is provided an improved process for the manufacture of a resin bonded abrasive article manufactured by blending a curable resin with an abrasive, shaping the resulting blend and curing the resin to form a resin bonded abrasive article. The improvement in the process comprises incorporating from about 0.2 to about 10 weight percent of particulate cuprous oxide into the blend prior to shaping the blend. The invention further comprises the resin bonded abrasive article manufactured in accordance with the process which article is a resin bonded abrasive article containing from about 0.2 to about 10 weight percent of particulate cuprous oxide.

[0009] The resin bonded abrasive article manufactured in accordance with the invention is usually in an abrasive grinding wheel which may be of any type such as a wheel for stock removal, polishing or cutoff applications. The resin bonded abrasive article may, however, be any abrasive article wherein the abrasive articles are bonded together with a resin. Other examples of such resin bonded abrasive articles include sharpening and honing stones, mounted points and segments.

[0010] The abrasive utilized in the abrasive article may be any abrasive grit or particle known to those skilled in the art including alumina, silica, zirconia, diamond, garnet, various fused and sintered combinations of alumina, zirconia and silica, and silicon carbide. The abrasive in the resin bonded abrasive article generally constitutes from about 79.8 to about 95.8 weight percent of the article. The average particle size of the abrasive is from about 90 to about 2 500 microns and usually from about 700 to about 1 000 microns.

[0011] The abrasive is held together or bonded by a resin which is cured after it is blended with the abrasive. The resin may be a curable liquid or solid resin or a combination of both liquid and solid resins.

[0012] The curable resin is any resin which can be cured to form a solid resin having sufficient strength and adhesion to securely bond the abrasive particles. Examples of such resins are phenolic resins and polyester resins. The most desirable resins are phenolic type resins including resol resins which are heat curable and novolac resins which require a curing agent such as hexamethylenetetramine or paraformaldehyde.

[0013] The preferred resin is a combination of a heat curable liquid resol and a solid novolac resin.

[0014] The curable liquid resin should not have a high molecular weight prior to curing to permit the resin to be blenbed with the abrasive particles. The curable liquid resin prior to curing should therefore have a viscosity of from between about 0.8 to a maximum of about 10,000 poise and desirably between about 10 and about 1 000 poise.

[0015] The most desirable liquid phenolic resin is a low viscosity liquid phenolic resin with a slow rate of cure having a viscosity at 25 °C of between about 325 and 450 centipoise and a gell time of about 35 minutes at 121 °C. Suitable liquid resins are commercially available from Varcum Chemical Division of Reichhold Chemical Inc. under the name of Varcum 8121 and from Georgia Pacific Corporation under the name of GP5080.

[0016] The most desirable powdered phenolic resin is a medium flow solid novolac resin containing from about 2 to about 15 weight percent, based upon weight of novolac resin, of hexamethylenetetramine. The resin may be any phenolic type novolac resin including those made from phenol and cresol. The most desirable powdered resin has a flow in millimeters of about 26 to 34. The flow is determined by heating a 10 mm diameter by 6 mm thick pallet of the resin at 125° ± 1 °C for three minutes on a glass plate, tilting the plate to 65° from the horizontal and continuing to heat at 125°C j: 1 °C for twenty minutes, cooling the plate in the horizontal position and measuring the flow of distance in millimeters. The most desirable resin also has an apparent density of about 0.33 grams per cc and contains from about 7.2 to about 7.7 percent hexamethylenetetramine. The melting point of the uncured resin is from about 90 to about 97 °C. Suitable solid resins are commercially available from the Carborundum Company under the name N2, from Ashland Chemical Division of Ashland Corporation under the name Arophene 875, from Varcum Chemical Co., Division of Reichhold Chemicals, Inc. under the name V7608 and from Borden Chemical Company, under the name Ad5991.

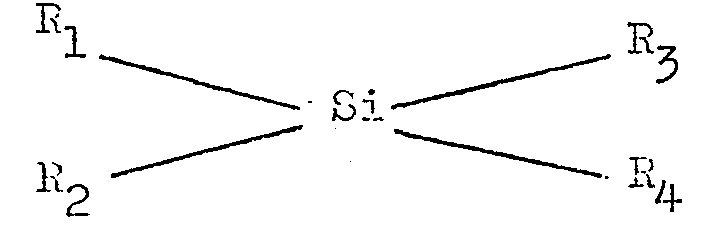

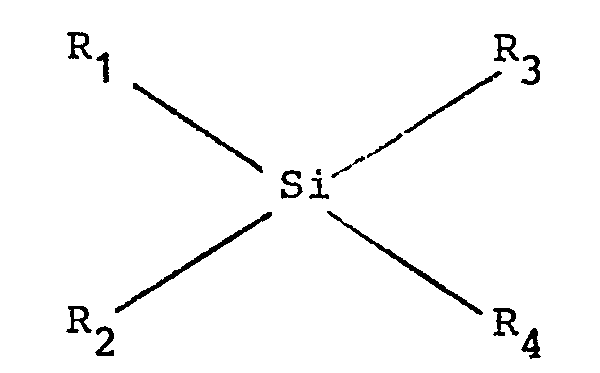

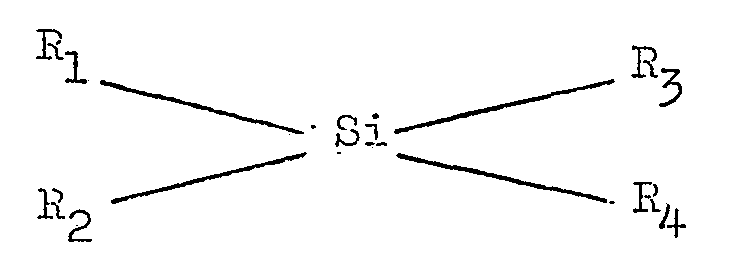

[0017] Desirably a wetting or dispersing agent is blended with the abrasive at the time of or prior to the blending of the abrasive with the liquid resin. Any effective agent known to those skilled in the art may be used. Examples of effective wetting agents are a liquid mixture of about 75 weight percent furfural and 25 weight percent cresol, colloidal silica and silanes. Wetting or dispersing agents may be used alone or in combination. Particularly effective dispersing agents are amine modified organosilanes. Such organosilanes preferably have the structural formula :

wherein the Ri, R2, R3 and R4 radicals are independently lower alkyl, lower alkoxy or amino lower alkyl provided that at least one of the radicals is lower alkoxy and at least one of the radicals is amino lower alkyl.

[0018] Lower alkyl as used herein means an alkyl radical containing from 1 to 4 carbon atoms inclusive. Examples of lower alkyl radicals are methyl, alkyl, propyl, isopropyl, butyl, isobutyl and tert-butyl.

[0019] Lower alkoxy used herein means an alkoxy containing from 1 to 4 carbon atoms inclusive. Examples of such lower alkoxy radicals are methoxy, ethoxy, propoxy and butoxy.

[0020] Amino lower alkyl as used herein means an amine radical containing from 1 to 5 carbon atoms inclusive. Examples of such radicals are amino propyl, dimethyl amino propyl, amino ethyl and methyl amino ethyl.

[0022] Suitable silanes may be commercially obtained from Union Carbide Silicone Division under the name A1100 Silane and from General Electric Company Silicones Products Division under the name SC-3901.

[0023] Desirably from about 0.05 to about 2 weight percent of amine modified organosilane is incorporated into the blend even when other additional dispersing or wetting agents are present. From about 0.05 to about 3 weight percent of such other agents are desirably also present, e.g. from about 0.05 to about 3 weight percent of colloidal silica dispersion (40 percent dispersion of colloidal silica in water).

[0024] In addition to abrasive, resin and wetting or dispersing agents, fillers such as fluorspar may be added and are desirably present in an amount of from about 5 to 25 weight percent of the total blend.

[0025] The resin and other components of the composition are blended with the abrasive particles by any suitable mixing apparatus known to those skilled in the art. Examples of such suitable mixing apparatus include the Lancaster type mixer having a containing drum which rotates in a direction opposite the rotation of mixing paddies, the high speed propeller type mixer, and the ball mill. After blending, the dispersion of the abrasive particles, resin, cuprous oxide (Cu20) and other components should be uniform.

[0026] Simultaneously with the blending of the abrasive particles with the other components of the composition or following the blending of the other components, particulate cuprous oxide is incorporated and blended with the composition. Desirably, the cuprous oxide has an average particle size of less than 20 microns, preferably less than 6 microns. From about 0.2 to about 10 percent, and preferably from about 0.5 to about 5 percent, cuprous oxide is added by weight of the blend.

[0027] The cuprous oxide may be added as pure cuprous oxide or may be blended with another component. Preblends of cuprous oxide with silicon carbide are particularly desirable, e.g. 79 weight percent CU20 blended with SiC having a particle size range of 5 to 30 microns and an average particle size of 15 microns.

[0028] It has been found that forming a preblend of cuprous oxide, or the blend of cuprous oxide with silicon carbide with the filler, if any, is present prior to incorporating with the abrasive resin blend, results in a more complete dispersion of the cuprous oxide into the composition. After blending, the blended composition is shaped. The shaping is usually accomplished by introducing the blend into a mould and subjecting the blend in the mould to a pressure of about 3 to about 300 kilograms per square centimeter at a temperature of from about 10 to about 100 °C and preferably at about 25 °C for from about 5 seconds to about 10 minutes.

[0029] After shaping the article, which desirably contains from about 5 to about 20 percent curable liquid resin, from about 79.8 to about 94.8 weight percent abrasive and from about 0.2 to about 10 percent cuprous oxide is then cured. The curing usually occurs at a temperature of from about 100 °C to about 225 °C for from about 1 to about 24 hours.

[0030] After curing, the resulting resin bonded abrasive article is found to have excellent strength as compared with similar articles manufactured in the prior art.

[0031] The following examples are for the purpose of illustrating, not limiting, the process and article of the invention.

Example 1

[0032] 3,700 grams of 24 grit aluminum oxide abrasive is introduced into a Lancaster type mixer having a rotating tub and paddles which rotate in a direction opposite the direction of rotation of the tub. The mixer is then activated and to the alumina abrasive by step wise addition are then added 5 cc of a wetting agent comprising 75 percent furfural and 25 percent cresol, 185 grams of Varcum 8121 liquid phenol resin, 465 grams of V7608 powdered phenolic resin having medium flow and 650 grams of fluorspar having an average particle size of 200 mesh.

[0033] The above ingredients are blended in a mill until the blend is uniform and about 500 grams of the resulting blend is introduced with two layers of fiber glass reinforcing cloth, into an abrasive wheel mould having inside mould dimensions of 6" by 1/4" (15 cm x 0.6 cm) thick with 1" (2.5 cm) diameter central hole. The material in the mould is then subjected with a pressure of 3,000 psi (210 kg cm-2) for 10 seconds. The resulting formed wheel is then dusted with zinc stearate powder and cured for 38 hours using the following sequence :

[0034] The wheel is then unloaded from curing oven when the temperature is about 52 °C or less. The resulting abrasive wheel is a bonded abrasive wheel manufactured in accordance with known prior art procedures.

Example II

[0035] Example I is repeated except that the 5 cc of the furfural-cresol liquid is eliminated and 5 cc of 40 percent suspension colloidal silica is added. The resulting wheel is found to have a higher burst speed, i.e. greater resistance to breaking under centrifugal force, than the grinding wheel manufactured in accordance with Example I.

Example III

[0036] Example I is repeated except 5 cc of 1100 ami- nofunctionalorganosilane is incorporated into the blend. The resulting abrasive wheel is found to have a higher burst speed than the wheel manufactured in accordance with Example I.

Example IV

[0037] Example II is repeated except 5 cc of A1100 amino substituted organosilane is incorporated into the blend. The resulting abrasive wheel is found to have a higher burst speed than the wheels manufactured in accordance with Examples I, II and III.

Example V

[0038] Example I is repeated except that 50 grams of a uniform mixture of 70 percent cuprous oxide (CU20) and 30 percent silicon carbide (SiC) having an average particle size of 15 is preblended with the powdered phenolic resin and the fluorspar and the preblend is then added to the aluminum oxide blend. The resulting wheel is found to have an improved burst speed over the burst speed of the wheel prepared in accordance with Example I.

Example VI

[0039] Example III is repeated except that 50 grams of the Cu20-SiC mix is preblended with the powdered phenolic resin and fluorspar. The resulting preblend is then incorporated into the aluminum oxide blend. The resulting wheel is found to have a burst speed which is superior to the burst speed of any of the wheels manufactured in accordance with Examples I through V.

Example VII

[0040] Example IV is repeated except that 50 grams of the Cu20-SiC mix is preblended with the powdered phenolic resin and fluorspar and the preblend is then incorporated into the aluminum oxide blend. The resulting abrasive wheel has a burst speed which is higher than the burst speeds of any of the wheels manufactured in accordance with Examples I through V and which is essentially the same as the burst speed manufactured in accordance with Example VI.

Example VIII

[0041] Example VII is repeated except that 50 grams of essentially pure cuprous oxide is substituted for the CU20-SiC mix. The resulting wheel has a burst speed which is approximately the same as the burst speed of the wheel prepared in accordance with Example VII.

Example IX

[0042] Six wheels are prepared in accordance with each of Examples, I, II, IV and VII. Twelve samples having a dimension of approximately 1" by 1/4" cross section (15 cm x 0.6 cm) are cut from three of the wheels prepared in accordance with each of the examples. The samples are then tested for tensile strength on an Instron apparatus. The remaining three wheels from each of the examples are tested for burst speed by mounting each of the wheels and turning them at increasingly higher speeds until a portion of the wheel flies free from the balance of the wheel. The tensile strength in kilograms and the burst speed in surface meters per minute (SMPM) are shown in Table I.

Table I shows that the addition of cuprous oxide in a blend used in making the abrasive wheel particularly when used in conjunction with colloidal silica and organosilane substantially increases both tensile strength and burst speed of the resulting wheel.

1. A process for the manufacture of a resin bonded abrasive article which comprises

blending a curable resin with an abrasive, shaping the resulting blend and curing

the resin to form a resin bonded abrasive article, characterised in that the process

comprises incorporating from about 0.2 to about 10 weight percent of particulate cuprous

oxide into the blend prior to shaping.

2. A process as claimed in claim 1 wherein the amount of particulate cuprous oxide

is about 0.2 to 5 weight percent.

3. A process as claimed in claim 1 or 2 wherein from about 0.05 to about 2 weight

percent of amine modified organosilane having the structural formula :

wherein the R1, R2, R3 and R4 radicals are independently lower alkyl, lower alkoxy or amino lower alkyl provided that at least one of said radicals is amino lower alkyl and at least one of said radicals is lower alkoxy, is incorporated into the blend.

wherein the R1, R2, R3 and R4 radicals are independently lower alkyl, lower alkoxy or amino lower alkyl provided that at least one of said radicals is amino lower alkyl and at least one of said radicals is lower alkoxy, is incorporated into the blend.

4. A process as claimed in any one of claims 1 to 3 wherein the cuprous oxide has

an average particle size of less than about 20 microns.

5. A process as claimed in any one of claims 1 to 4 wherein the resin is a phenolic

resin, comprising a combination of a liquid resol phenolic resin and a solid novolac

phenolic resin, cured with hexamethyienetetramine.

6. A process as claimed in any one of claims 1 to 5 wherein from about 0.05 to about

3 weight percent of colloidal silica, having an average particle size of less than

about 6 microns, is incorporated into the blend.

7. A process as claimed in claim 5, wherein the resin comprises a mixture of a solid

novolac phenolic resin cured with from about 2 to about 15 percent by weight of resin

of hexamethylenetetramine and a liquid resol phenolic resin which cures upon application

of heat.

8. A process as claimed in any one of claims 1 to 7 wherein at least a portion of

said resin prior to curing is a liquid having a viscosity of from about 0.80 to about

10,000 poise.

9. A process as claimed in claim 8 wherein at least a portion of said resin prior

to curing has a viscosity of from about 10 to about 1000 poise.

10. A process as claimed in any one of claims 1 to 9 wherein said blend is shaped

in a mould at a temperature of from about 10 to about 100 °C at a pressure of from

about 3 to about 300 kilograms per square centimeter for from about 5 seconds to about

10 minutes.

11. A process as claimed in any one of claims 1 to 10 wherein said shaped article

is cured at from about 100 °C to about 225 °C for from about 1 to about 24 hours.

12. An abrasive article comprising an abrasive bonded with from about 5 to about 20

weight percent of a cured resin, characterised in that the abrasive article contains

from about 0.2 to about 10 weight percent cuprous oxide.

13. An abrasive article as claimed in claim 12 wherein the amount of cuprous oxide

is from about 0.2 to about 5 weight percent cuprous oxide.

14. An abrasive article as claimed in claim 12 or 13 wherein said cured resin further

contains from about 0.05 to about 2 weight percent of an organosilane having the structural

formula :

wherein the R1' R2, R3 and R4 radicals are independently lower alkyl, lower alkoxy or amino lower alkyl provided that at least one of said radicals is amino lower alkyl and at least one of said radicals is lower alkoxy.

wherein the R1' R2, R3 and R4 radicals are independently lower alkyl, lower alkoxy or amino lower alkyl provided that at least one of said radicals is amino lower alkyl and at least one of said radicals is lower alkoxy.

1. Verfahren zum Herstellen eines mit einem Harz gebundenen Schleifgegenstandes, wobei

ein nachbehandelbares Harz mit einem Schleifstoff gemischt wird, diese Mischung zum

Schleifgegenstand geformt wird und der geformte Schleifgegenstand gealtert wird, gekennzeichnet

durch das Einarbeiten von etwa 0.2 bis 10 Gewichts-% korpuskularen Kupfer-I-Oxides

in die Mischung vor dem Formen.

2. Verfahren nach Anspruch 1, gekennzeichnet durch einen korpuskularen Kupfer-I-Oxid-Anteil

etwa zwischen 0.2 und 5 Gewichts-%.

3. Verfahren nach Anspruch 1 oder Anspruch 2, gekennzeichnet durch das Einarbeiten

von etwa 0.05 bis 2 Gewichts-% von mit Amin modifiziertem Organosilan mit der Strukturformel

worin R1, R2, R3 und R4-Reste unabhängig voneinander niedere Alkyl-, niedere Alkoxi- oder niedere Aminoalkylgruppen sind, vorausgesetzt, daß mindestens einer dieser Reste eine niedere Alkoxigruppe ist.

worin R1, R2, R3 und R4-Reste unabhängig voneinander niedere Alkyl-, niedere Alkoxi- oder niedere Aminoalkylgruppen sind, vorausgesetzt, daß mindestens einer dieser Reste eine niedere Alkoxigruppe ist.

4. Verfahren nach einem der Ansprüche 1 bis 3, dadurch gekennzeichnet, daß das Kupfer-I-Oxid

eine durchschnittliche Teilchengröße von weniger als etwa 20 Micron hat.

5. Verfahren nach einem der Ansprüche 1 bis 4, dadurch gekennzeichnet, daß das Harz

ein phenolisches Harz ist, das eine Kombination von einem flüssigen Resol-haltigen

phenolischen Harz und einem novolak-haltigen phenolischen Harz enthält, das mit Hexamethylentetramin

gealtert wird.

6. Verfahren nach einem der Ansprüche 1 bis 5, dadurch gekennzeichnet, daß etwa 0.05

bis 3 Gewichts-96 kolloidale Kieselerde mit einer durchschnittlichen Teilchengröße

von weniger als etwa 6 Micron in die Mischung eingearbeitet wird.

7. Verfahren nach Anspruch 5, dadurch gekennzeichnet, daß das Harz eine Mischung aus

einem festen Novolac-haltigen phenolischen Harz, das mit etwa 2 bis etwa 15 Gewichts-%

Hexamethylentetraminharz gealtert ist, und einem flüssigen Resol-haltigen phenolischen

Harz besteht, das durch die Zufuhr von Hitze gealtert ist.

8. Verfahren nach einem der Ansprüche 1 bis 7, dadurch gekennzeichnet, daß mindestens

ein Teil des Harzes vor dem Altern eine Flüssigkeit mit einer Viskosität von etwa

0.80 bis etwa 10.000 Poise ist.

9. Verfahren nach Anspruch 8, dadurch gekennzeichnet, daß mindestens ein Teil des

Harzes vor dem Altern eine Viskosität von etwa 10 bis etwa 1 000 Poise hat.

10. Verfahren nach einem der Ansprüche 1 bis 8, dadurch gekennzeichnet, daß die Mischung

in einer Preßform hergestellt wird bei einer Temperatur von etwa 10 bis 100 °C, bei

einem Druck von etwa 3 bis 300 kg/cm2 und während etwa 5 Sec. bis 10 Min.

11. Verfahren nach einem der Ansprüche 1 bis 10, dadurch gekennzeichnet, daß der geformte

Schleifgegenstand bei etwa 100° bis 225 °C etwa 1 bis 24 Stunden lang nachgealtert

wird.

12. Schleifstoffgegenstand mit einem Schleifmittel, das an etwa 5 bis 20 Gewichts-%

nachbehandeltes Harz gebunden ist, dadurch gekennzeichnet, daß der Schleifstoffgegenstand

etwa 0.2 bis 10 Gewichts-% Kupfer-I-Oxid enthält.

13. Schleifstoffgegenstand nach Anspruch 12, dadurch gekennzeichnet, daß der Schleifgegenstand

etwa 2.5 bis 5 Gewichts-% Kupfer-i-Oxid enthält.

14. Schleifstoffgegenstand nach Anspruch 12 oder 13, dadurch gekennzeichnet, daß das

nachbehandelte Harz des weiteren etwa 0.05 bis etwa 2 Gewichts-% eines Organosilans

mit der Strukturformel enthält :

worin die R1, R2, R3 und R4-Reste voneinander unabhängig niedere Alkyl-, niedere Alkoxi- oder niedere Aminoalkylgruppen sind, vorausgesetzt, daß mindestens einer der Reste eine niedere Aminoalkylgruppe und mindestens einer der Reste eine niedere Alkoxigruppe ist.

worin die R1, R2, R3 und R4-Reste voneinander unabhängig niedere Alkyl-, niedere Alkoxi- oder niedere Aminoalkylgruppen sind, vorausgesetzt, daß mindestens einer der Reste eine niedere Aminoalkylgruppe und mindestens einer der Reste eine niedere Alkoxigruppe ist.

1. Procédé de production d'un article abrasif lié par une résine, impliquant le mélange

d'une résine mûrissable avec un abrasif, le façonnage du mélange résultant et la maturation

de la résine pour former un article abrasif lié par la résine, procédé caractérisé

par le fait qu'il consiste à incorporer environ 0,2 à environ 10% en poids d'oxyde

cuivreux en particules au mélange avant le façonnage.

2. Procédé suivant la revendication 1, caractérisé en ce que la quantité d'oxyde cuivreux

en particules est d'environ 0,2 à 5 % en poids.

3. Procédé suivant la revendication 1 ou 2, caractérisé par le fait qu'une quantité

d'environ 0,05 à environ 2 % en poids d'un organosilane modifié par une amine, de

formule :

(dans laquelle les radicaux R1, R2, R3 et R4 représentent, indépendamment les uns des autres, un radical alkyle inférieur, un radical alkoxy inférieur ou un radical amino-alkyle inférieur, à condition qu'au moins l'un de ces radicaux soit un radical amino-alkyle inférieur et qu'au moins l'un de ces radicaux soit un radical alkoxy inférieur), est incorporée au mélange.

(dans laquelle les radicaux R1, R2, R3 et R4 représentent, indépendamment les uns des autres, un radical alkyle inférieur, un radical alkoxy inférieur ou un radical amino-alkyle inférieur, à condition qu'au moins l'un de ces radicaux soit un radical amino-alkyle inférieur et qu'au moins l'un de ces radicaux soit un radical alkoxy inférieur), est incorporée au mélange.

4. Procédé suivant l'une quelconque des revendications 1 à 3, caractérisé en ce que

les particules d'oxyde cuivreux ont un diamètre moyen inférieur à environ 20 micromètres.

5. Procédé suivant l'une quelconque des revendications 1 à 4, caractérisé en ce que

la résine est une résine phénolique, comprenant en association une résine phénolique

liquide du type résol et une résine phénolique solide du type novolaque, mûrie à l'hexaméthylènetétramine.

6. Procédé suivant l'une quelconque des revendications 1 à 5, dans lequel environ

0,05 à environ 3 % en poids de silice colloïdale, ayant un diamètre moyen de particules

inférieur à environ 6 micromètres, sont incorporés au mélange.

7. Procédé suivant la revendication 5, caractérisé en ce que la résine comprend un

mélange d'une résine phénolique solide du type novolaque mûrie avec environ 2 à environ

15 %, en poids de résine, d'hexaméthylènetétramine et d'une résine phénolique liquide

du type résol qui mûrit sous l'action de la chaleur.

8. Procédé suivant l'une quelconque des revendications 1 à 7, caractérisé en ce qu'au

moins une portion de ladite résine, avant la maturation, est un liquide ayant une

viscosité d'environ 0,08 à environ 1000 Pa.s.

9. Procédé suivant la revendication 8, caractérisé en ce qu'au moins une portion de

ladite résine, avant la maturation, a une viscosité d'environ 1,0 à environ 100,0

Pa.s.

10. Procédé suivant l'une quelconque des revendications 1 à 9, caractérisé en ce que

le mélange est mis en forme dans un moule à une température d'environ 10 à environ

100 °C sous une pression d'environ 0,3 à environ 30,0 MPa pendant une période d'environ

5 secondes à environ 10 minutes.

11. Procédé suivant l'une quelconque des revendications 1 à 10, caractérisé en ce

que l'article mis en forme est mûri à une température d'environ 100 à environ 225°C

pendant une période d'environ 1 à environ 24 heures.

12. Article abrasif comprenant un abrasif lié par une proportion d'environ 5 à environ

20 % en poids d'une résine mûrie, caractérisé en ce qu'il contient environ 0,2 à environ

10 % en poids d'oxyde cuivreux.

13. Article abrasif suivant la revendication 12, caractérisé en ce que la quantité

d'oxyde cuivreux va d'environ 0,2 à environ 5 % en poids.

14. Article abrasif suivant la revendication 12 ou 13, caractérisé en ce que la résine

mûrie renferme en outre environ 0,05 à environ 2 % en poids d'un organosilane répondant

à la formule :

dans laquelle les radicaux R1' R2, R3 et R4 repré- ,sentent, indépendamment les uns des autres, un radical alkyle inférieur, alkoxy inférieur ou amino-alkyle inférieur, à condition qu'au moins l'un de ces radicaux soit un radical alkyle inférieur et qu'au moins l'un de ces radicaux soit un radical alkoxy inférieur.

dans laquelle les radicaux R1' R2, R3 et R4 repré- ,sentent, indépendamment les uns des autres, un radical alkyle inférieur, alkoxy inférieur ou amino-alkyle inférieur, à condition qu'au moins l'un de ces radicaux soit un radical alkyle inférieur et qu'au moins l'un de ces radicaux soit un radical alkoxy inférieur.