| (19) |

|

|

(11) |

EP 0 052 338 B1 |

| (12) |

EUROPEAN PATENT SPECIFICATION |

| (45) |

Mention of the grant of the patent: |

|

25.07.1984 Bulletin 1984/30 |

| (22) |

Date of filing: 11.11.1981 |

|

| (51) |

International Patent Classification (IPC)3: A44B 18/00 |

|

| (54) |

Hooked fabric fastener tape and method of producing same

Mit Haken versehenes Stoffbefestigungsband und Verfahren zu dessen Herstellung

Ruban de fixation à crochets en tissu et son procédé de fabrication

|

| (84) |

Designated Contracting States: |

|

BE DE FR GB IT |

| (30) |

Priority: |

14.11.1980 JP 160612/80

|

| (43) |

Date of publication of application: |

|

26.05.1982 Bulletin 1982/21 |

| (71) |

Applicant: YOSHIDA KOGYO K.K. |

|

Chiyoda-ku,

Tokyo (JP) |

|

| (72) |

Inventor: |

|

- Tsubata, Noritaka

Uozu-shi

Toyama-ken (JP)

|

| (74) |

Representative: Casalonga, Axel et al |

|

BUREAU D.A. CASALONGA - JOSSE

Morassistrasse 8

80469 München

80469 München (DE) |

|

| |

|

| Note: Within nine months from the publication of the mention of the grant of the European

patent, any person may give notice to the European Patent Office of opposition to

the European patent

granted. Notice of opposition shall be filed in a written reasoned statement. It shall

not be deemed to

have been filed until the opposition fee has been paid. (Art. 99(1) European Patent

Convention).

|

[0001] The present invention relates generally to surface type fasteners known as hook-and-loop

fasteners, and more particularly to a fabric fastener tape carrying on its one surface

a number of hook-shaped material engaging elements and a method of producing such

a hooked fabric fastener tape.

[0002] According to a known method, a hooked fabric fastener tape of the type described

is produced from a terry or uncut pile fabric carrying on its one surface a number

of loops raised from the one surface, each of the loops having a pair of spaced leg

sections and a head section interconnecting the leg sections (US-A-3154837). Each

loop is cut open or severed at one of the leg sections thereof to produce, on one

hand, a hook-shaped material engaging element and, on the other hand, a stem. The

prior art hooked fabric fastener tape is disadvantageous in that after the loops have

been cut open, the stems remain on the fastener tape adjacent to the corresponding

hook-shaped material engaging elements in confronting relation to or substantially

in vertical alignment with the respective free ends thereof. The stems are liable

to hinder cooperating loops on a mating looped fabric fastener tape from being introduced

into and hooked by the hook-shaped material engaging elements as the two fastener

tapes are pressed into face-to-face contact together. As a result, the possibility

of hooking between hooks and loops, and hence the firmness of engagement of a hook-and-loop

fastener is considerably decreased. In order to displace the hook-shaped material

engaging elements away from the stems, the prior art method needs to include an additional

treatment by a raising machine or another complicate and expensive device.

[0003] According to a first aspect of the invention, there is provided a hooked fabric fastener

tape comprising a foundation structure including a weft thread, a plurality of first

warp threads and a plurality of second warp threads of synthetic resin material in

the form of raised pile threads consisting of a number of pairs of hook-shaped material

engaging elements and stems, each pair of which has been produced from one loop.

[0004] The respective free ends of said hook-shaped material engaging elements are displaced

angularly away from said stems as viewed from the general plane of said foundation

structure.

[0005] According to a second aspect of the invention, there is provided a method of producing

a hooked fabric fastener tape comprising the steps of: weaving together a weft thread,

a plurality of first warp threads and a plurality of second warp threads of thermoplastic

synthetic resin material, so as to form loops with said second warp threads on one

of opposite surfaces of the so woven foundation structure, each of said loops having

a pair of leg sections and a head section interconnecting said leg sections; heating

said loops to cause the loops to retain their shape to form raised pile threads; and

cutting each said loop at one of said leg sections thereof, whereby producing a hook-shaped

material engaging element and a stem, while being woven, said second warp threads

are submitted to a torque, said loops are heated at a temperature which allows the

loops to retain an internal torsional stress stored during said weaving step and upon

cutting the loops, said hook-shaped material engaging elements and the stems are allowed

to displace, due to said internal torsional stress, angularly away from one another

as viewed from the general plane of said woven foundation structure.

[0006] The present invention seeks to provide a hooked fabric fastener tape for hook-and-loop

fasteners which can adhere to or engage with a cooperating looped fabric fastener

tape with an increased degree of firmness.

[0007] The invention also seeks to provide a hooked fabric fastener tape having hook-shaped

material engaging elements which can hook cooperating loops of a mating looped fabric

fastener reliably without causing mis-engagement therewith.

[0008] The invention further seeks to provide a method which produces such a hooked fabric

fastener tape simply and less costly.

[0009] The above and other objects, advantages and features of the present invention will

become apparent from the following description of a preferred embodiment taken in

conjunction with the accompanying drawings, in which:

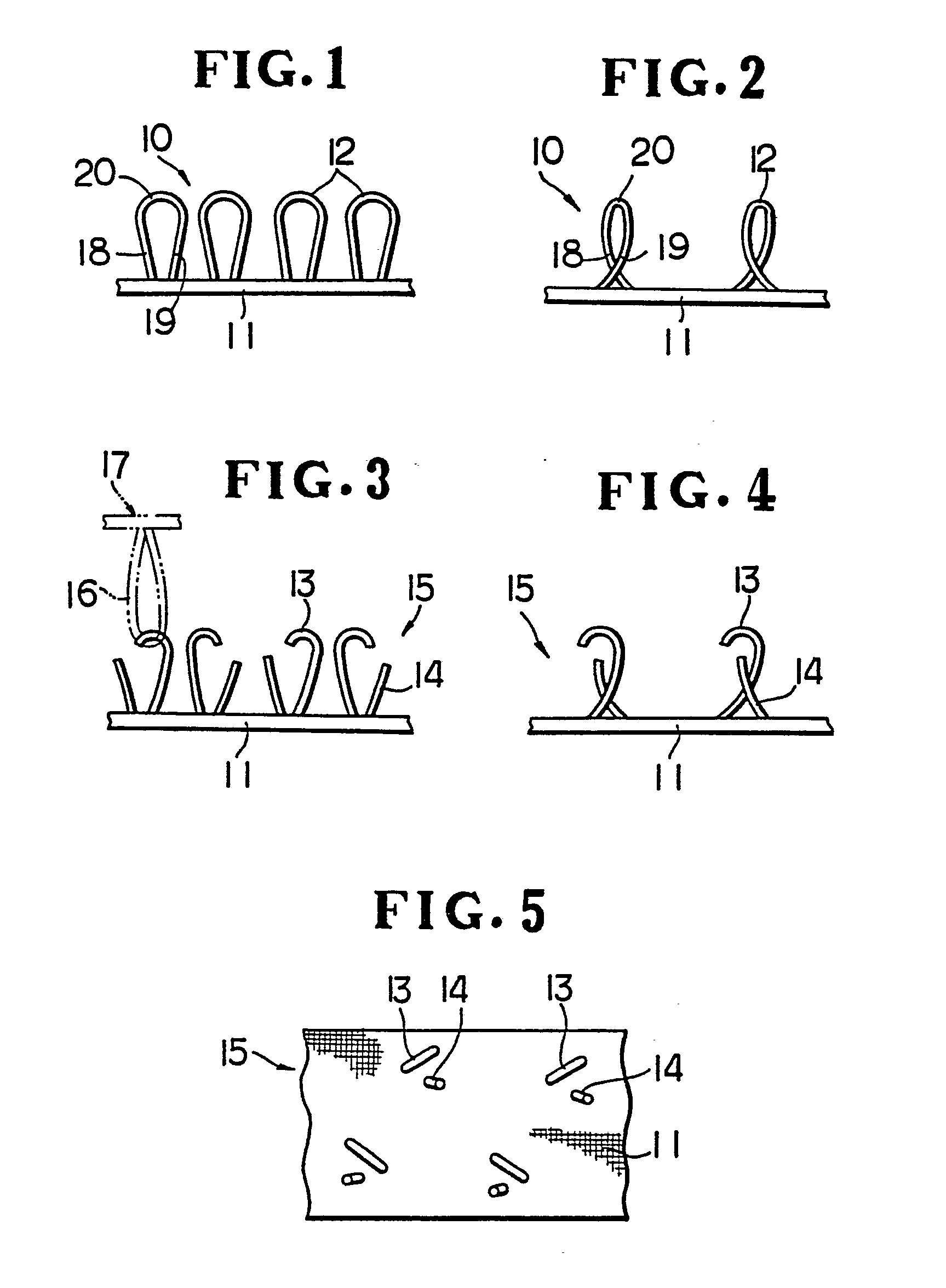

Figure 1 is a fragmentary diagrammatic front elevational view of loops on a foundation

structure before being converted into a hooked fabric fastener tape according to the

invention;

Figure 2 is a side elevational view of Figure 1;

Figures 3 and 4 are views similar to Figures 1 and 2, respectively, showing a hooked

fabric fastener tape having one one of opposite surfaces of a foundation structure

a plurality of hook-shaped material engaging elements and stems which have been produced

by cutting the loops at respective one leg sections thereof shown in Figures 1 and

2, according to the present invention; and

Figure 5 is a plan view of Figure 3.

[0010] Referring now to the drawing, wherein like reference characters designate identical

or corresponding parts throughout the several views, and more particularly to Figures

1 and 2, there is shown an uncut pile or looped fabric fastener tape 10 produced in

accordance with the present invention. The looped fabric fastener tape 10 includes

a foundation structure 11 constituted by a weft thread and a plurality of first warp

threads woven with the weft thread (these threads being not shown for clarification).

[0011] The fastener tape 10 also includes on one of opposite surfaces of the foundation

structure 11 a number of loops 12 formed with a plurality of second warp threads woven

into the foundation structure during the weaving operation of the same in a loom of

the general type employed in weaving velvet ribbon. Each of the loops 12 has a pair

of leg sections 18, 19 and a head section 20 interconnecting the leg sections 18,

19. The second warp threads preferably are thermoplastic monofilaments made of a synthetic

resin material, such as nylon or other material capable of being set by heat into

a predetermined shape.

[0012] The second warp threads are woven, while submitted to a torque or torsional load,

together with the foundation weft and warp threads, with the result that the loops

12 formed with thus twisted warp threads are twisted correspondingly as shown in Figure

2. Exertion of the torque or twist may be done either as the second warp threads are

supplied into the loom for formation of the loops 12 or as they are wound on bobbins,

with the aid of a suitable torque exertion means.

[0013] The loops 12 are heated at a temperature which causes the loops 12 to retain their

shape to form raised pile threads while allowing the same to retain an internal torsional

stresses stored during the weaving operation. The heating temperature of the loops

12 is preferably set at a relatively low temperature in a range within which the second

warp threads of thermoplastic synthetic resin material retain their thermoplasticity.

[0014] Each of loops 12 is then cut open or severed at one 18 of the respective leg sections

18, 19 to produce, on one hand, a hook-shaped material engaging element 13 formed

jointly with the other leg section 19, the head section 20 and a part of the one leg

section 18 and, on the other hand, a stem 14 formed with the remainder of the cut

one leg section 18 and constituting a dressed nap, whereupon the hook-shaped material

engaging element and the stem 13, 14 are allowed to displace, due to the internal

torsional stress stored therein, angularly away from each other as viewed from the

general plane of the foundation structure 11, as shown in Figures 3 to 5. Thus, a

large opening is provided between the free end of the hook-shaped element 13 and the

stem 14 for easy reception of a corresponding loop 16 on a mating looped fabric fastener

tape 17 (shown by phantom lines in Figure 3). A hooked fabric fastener tape 15 now

converted from the looped fabric fastener tape 10 has the hook-shaped material engaging

elements 13 which allow the cooperating loops 16 on the looped fabric fastener tape

17 to enter into hooking engagement therewith smoothly and reliably as the two fastener

tapes 15, 17 are pressed together. As a result, the possibility of hooking between

hooks and loops, i.e. the firmness of engagement of a fastener is substantially increased.

[0015] Following to the loop-heating operation and prior to the loop-cutting operation,

the fastener tape 10 may be subjected to additional treatments at the desire, such

as dyeing and fixing of the loops 12 to the foundation structure 11. The latter operation

may be effected by coating or impregnating on the other or reverse surface of the

foundation structure 11 with an adhesive or a heat settable resin capable of withstanding

such temperatures as are likely to be encountered in normal usage of a hook-and-loop

fastener of which the hooked fabric fastener tape 15 forms a part.

1. A hooked fabric fastener tape comprising a foundation structure (11) including

a weft thread, a plurality of first warp threads and a plurality of second warp threads

of synthetic resin material in the form of raised pile threads consisting of a number

of pairs of hook-shaped material engaging elements (13) and substantially straight

stems (14), each pair of which has been produced from cutting one loop (12), the respective

free ends of said hook-shaped material engaging elements being curved toward said

foundation structure, characterized in that the respective free ends of said hook-shaped

material engaging elements are displaced angularly away from said stems (14) as viewed

from the general plane of said foundation structure (11). ).

2. A hooked fabric fastener tape according to claim 1, characterized in that the free

end of each respective hook-shaped material engaging element (13) defines a first

plane of coincidence generally perpendicular to the surface of the foundation structure,

and that the respective stem (14) is coincident with a second plane of coincidence

generally perpendicular to the surface of the foundation structure (11), said first

and second planes of coincidence being distinct from each other and intersecting each

other at an angle of displacement.

3. A hooked fabric fastener tape according to claims 1 or 2, characterized in that

each of said pile threads (13, 14) is formed with a thermoplastic monofilament.

4. A method of producing a hooked fabric fastener tape comprising the steps of: weaving

together a weft thread, a plurality of first warp threads and a plurality of second

warp threads of thermoplastic synthetic resin material, so as to form loops (12) with

said second warp threads on one of opposite surfaces of the so woven foundation structure

(11), each of said loops having a pair of leg sections (18, 19) and a head section

20 interconnecting said leg sections; heating said loops (12) to cause the loops to

retain their shape to form raised pile threads; and cutting each said loop (12) at

one of said leg sections (18, 19) thereof, whereby producing a hook-shaped material

engaging element (13) and a stem (14), characterized in that while being woven, said

second warp threads are exerted thereon a torque, that said loops (12) are heated

at a temperature which allows the loops (12) to retain an internal torsional stress

stored during said weaving step and in that upon cutting the loops (12), said hook-shaped

material engaging elements (13) and the stems (14) are allowed to displace, due to

said internal torsional stress, angularly away from one another as viewed from the

general plane of said woven foundation structure (11).

5. A method according to claim 4, characterized in that said heating temperature is

set at a relatively low temperature in a range within which said second warp threads

of thermoplastic synthetic resin material retain their thermoplasticity.

6. A method according to claim 4 or 5, characterized in that each of said second warp

threads comprises a thermoplastic monofilament.

1. Ruban de fixation en tissu à crochets comprenant une structure de base (11) comprenant

un fil de trame, une pluralité de premiers fils de chaîne et une pluralité de secondes

fils de chaîne en résine synthétique formant des fils-poils dressés constitués d'un

grand nombre de paires d'éléments d'accrochage (13) en forme de crochets et de tiges

(14) sensiblement droites, chacune de ces paires étant obtenue à partir du sectionnement

d'une boucle (12), les extrémités libres respectives desdits éléments d'accrochage

en forme de crochets étant recourbées vers la structure de base, caractérisé en ce

que les extrémités libres respectives desdits éléments d'accrochage en forme de crochets

sont écartées angulairement desdites tiges (14), vues du plan générale de ladite structure

de base (11).

2. Ruban de fixation en tissu à crochets selon la revendication 1, caractérisé en

ce que l'extrémité libre de chaque élément d'accrochage respectif (13) en forme de

crochet définit un premier plan de coïncidence généralement perpendiculaire à la surface

de la structure de base, et en ce que la tige respective (14) est contenue dans un

second plan de coïncidence généralement perpendiculaire à la surface de la structure

de base ( 1 1 lesdits premier et second plans de coîncidence étant distincts l'un

de l'autre et s'intersectant l'un l'autre selon un écart angulaire.

3. Ruban de fixation en tissu à crochets selon les revendications 1 ou 2, caractérisé

en ce que chacun desdits fils-poils (13, 14) est formé par un monofilament thermoplastique.

4. Procédé de fabrication d'un ruban de fixation en tissu à crochets comprenant les

phases consistant à: tisser ensemble un fil de trame, une pluralité de premiers fils

de chaîne et une pluralité de seconds fils de chaîne en résine synthétique thermoplastique,

de mainère à former des boucles (12) avec lesdits seconds fils de chaîne sur l'une

des faces opposées de ladite structure de base (11) ainsi tissée, chacune desdites

boucles comportant une paire de sections formant branches (18, 19) et une section

formant tête (20) reliant lesdites sections formant branches; chauffer lesdites boucles

(12) pour les amener à garder leur forme de manière à constituer des fils-poils dressés;

et sectionner chaque boucle (12) dans l'une de ses sections formant branches (18,

19) précitées, en réalisant ainsi un élément d'accrochage (13) en forme de crochets

et une tige (14), caractérisé en ce que pendant leur tissage, on éxerce un couple

sur lesdits seconds fils de chaîne, en ce que l'on chauffe lesdites boucles (12) à

une température qui permet à ces boucles de retenir une contrainte de torsion interne

emmagasinée pendant ladite phase de tissage et en ce que le sectionnement des boucles

(12) permet auxdits éléments d'accrochage (13) en forme de crochets et aux tiges (14)

de s'écarter angulairement les uns des autres sous l'action de la contrainte de torsion

interne, vus du plan générale de ladite structure de base tissée (11).

5. Procédé selon la revendication 4, caractérisé en ce que l'on règle ladite température

de chauffage à une valeur relativement faible dans une plage où lesdits seconds fils

de chaîne en résine synthétique thermoplastique gardent leur thermoplasticité.

6. Procédé selon les revendications 4 ou 5, caractérisé en ce que chacun desdits seconds

fils de chaîne comprend un monofilament thermoplastique.

1. Ein hakenförmiges Stoffbefestigungsband bestehend aus einem Grundgefüge (11) einschließlich

eines Einschlagfadens, einer Mehrzahl von ersten Kettenfäden und einer Mehrzahl von

zweiten Kettenfäden aus synthetischem Harzmaterial in Form von erhebenen Polkettenfäden

bestehend aus einer Anzahl von Paaren der hakenförmigen stoffeingreifenden Elementen

(13) und im wesentlichen geraden Stielen (14), wovon aus jedem Paar durch Schneiden

eine Schlinge (12) hergestellt wird, die jeweiligen freien Enden des genannten hakenförmigen

stoffeingreifenden Elementen sind in Richtung des genannten Grundgefüges gebogen,

dadurch gekennzeichnet, daß die jeweiligen freien Enden der genannten hakenförmigen

stoffeingreifenden Elementen aus Sicht der allgemeinen Ebene des genannten Grundgefüges

(11) von den genannten Stielen (14) versetzt sind.

2. Ein hakenförmiges Stoffbefestigungsband nach Anspruch 1, dadurch gekennzeichnet,

daß das freie Ende des jeweiligen hakenförmigen stoffeingreifenden Element eine erste

Deckungsebene bildet, die allgemein rechtwinkelig zur Fläche des Grundgefüges liegt,

und daß der jeweilige Stiel (14) mit einer zweiten Deckungsebene deckungsgleich ist,

die allgemein rechtwinkelig zur Fläche des Grundgefüges (11) liegt, und daß sich die

genannten ersten und zweiten Deckungsebenen voneinander unterscheiden und sich in

einem Versetzungswinkel schneiden.

3. Ein hakenförmiges Stoffbefestigungsband nach Anspruch 1 oder 2, dadurch gekennzeichnet,

daß jeder der genannten Polkettenfäden (13, 14) mit einer thermoplastischen Monofaser

gebildet wird.

4. Ein Verfahren zur Herstellung eines hakenförmigen Stoffbefestigungsbandes bestehend

aus den Stufen: Zusammenweben eines Einschlagfadens, einer Mehrzahl von ersten Kettenfäden

und einer Mehrzahl von zweiten Kettenfäden aus thermoplastischem synthetischem Harzmaterial,

um mit den genannten zweiten Kettenfäden Schlingen (12) auf einer der entgegengesetzten

Flächen des auf diese Weise gewebten Grundgefüges (11) zu bilden, wovon jede der genannten

Schlingen ein Paar Schenkelabschnitte (18, 19) und einen dieser Schenkelabschnitte

verbindenden Kopfabschnitt (20) aufweist; Aufheizen der genannten Schlingen (12),

die Schlingen zu veranlassen, ihre Form aufrechtzuerhalten, um erhebene Polkettenfäden

zu bilden; und Abschneiden jeder genannten Schlinge, an einem deren genannten Schenkelabschnitte

(18, 19), wobei ein hakenförmiges stoffeingreifendes Element (13) und ein Stiel (14)

hergestellt werden, dadurch gekennzeichnet, daß beim Weben ein Drehmoment auf die

genannten zweiten Kettenfäden aufgebracht wird, daß die genannten Schlingen bei einer

Temperatur geheizt werden, die es ermöglicht, daß die Schlingen eine während der genannten

Webstufe gespeicherte interne Drehspannung behalten und daß nach Abschneiden der Schlingen

(12) die genannten hakenförmigen stoffeingreifenden Elemente (13) und die Stiele (14)

wegen der genannten internen Drehspannung winkeling voneinander gesehen von der allgemeinen

Ebene des genannten gewebten Grundgefüges (11) aus versetzen können.

5. Ein Verfahren nach Anspruch 4, dadurch gekennzeichnet, daß die genannte Heiztemperatur

auf eine verhältnismäßig niedrige Temperatur in einem Bereich eingestellt wird, innerhalb

dessen die genannten zweiten Kettenfäden aus thermoplastischem synthetischem Harzmaterial

ihre Thermoplastizität behalten.

6. Ein Verfahren nach Anspruch 4 oder 5, dadurch gekennzeichnet, daß jeder der genannten

zweiten Kettenfäden eine thermoplastische Monofaser umfaßt.