| (19) |

|

|

(11) |

EP 0 215 161 A1 |

| (12) |

EUROPEAN PATENT APPLICATION |

| (43) |

Date of publication: |

|

25.03.1987 Bulletin 1987/13 |

| (22) |

Date of filing: 08.08.1985 |

|

| (51) |

International Patent Classification (IPC)4: B68C 1/02 |

|

| (84) |

Designated Contracting States: |

|

DE FR GB IT SE |

| (71) |

Applicant: CARBINE NOMINEES PTY. LTD. |

|

Perth

Western Australia (AU) |

|

| (72) |

Inventor: |

|

- Bates, Kenneth John

Perth

Western Australia (AU)

|

| (74) |

Representative: Matthews, Graham Farrah et al |

|

BROOKES & MARTIN

Incorporating

MATTHEWS, HADDAN & CO.

High Holborn House

52/54, High Holborn

London, WC1V 6SE

London, WC1V 6SE (GB) |

|

| |

|

| (54) |

Improved saddle tree |

(57) As discussed in our Australian Patent 524616 over recent years and with the advance

of technology many improvements have been made to the construction techniques in saddlery

and in the materials used. Many years ago saddles were constructed by building up

or adding on various saddle components to what was a conventional wooden saddle tree.

With the advance of technology we saw the introduction of saddle trees formed from

rigid plastics material and when thin light racing saddles were required the insertion

of thin carbon rods or straws. The carbon rods giving the desired strength to the

saddle tree. Developments of this nature saw the saddle tree being formed complete

with seat cantle and pommel.

|

|

[0001] As discussed in our Australian Patent 524616 over recent years and with the advance

of technology many improvements have been made to the construction techniques in saddlery

and in the materials used. Many years ago saddles were constructed by building up

or adding on various saddle components to what was a conventional wooden saddle tree.

With the advance of technology we saw the introduction of saddle trees formed from

rigid plastics material and when thin light racing saddles were required the insertion

of thin carbon rods or straws. The carbon rods giving the desired strength to the

saddle tree. Developments of this nature saw the saddle tree being formed complete

with seat, cantle and pommel.

[0002] One problem in the area of saddle construction was that economies of scale could

not be fully utilised as different moulds were required for different sized saddles

i.e. greater or less distance between the pommel and the cantle for different age

groups and sizes of riders.

[0003] One of the objects of this invention is to produce a method of construction of a

saddle tree whereby standardising of two moulds can give an extensive number of varying

sized saddles.

[0004] In one form the invention resides in an improved saddle tree wherein the saddle tree

is formed from two moulded members, first said member comprising the pommel and seat

of a saddle and the second of said members comprising the cantle, said cantle member

adapted to be secured to the seat of the saddle in a pre-selected position thereby

governing the size of the saddle and distance between the pommel and cantle.

[0005] The invention will be better understood by reference to the following description

of one specific embodiment as shown in the accompanying drawings wherein:-

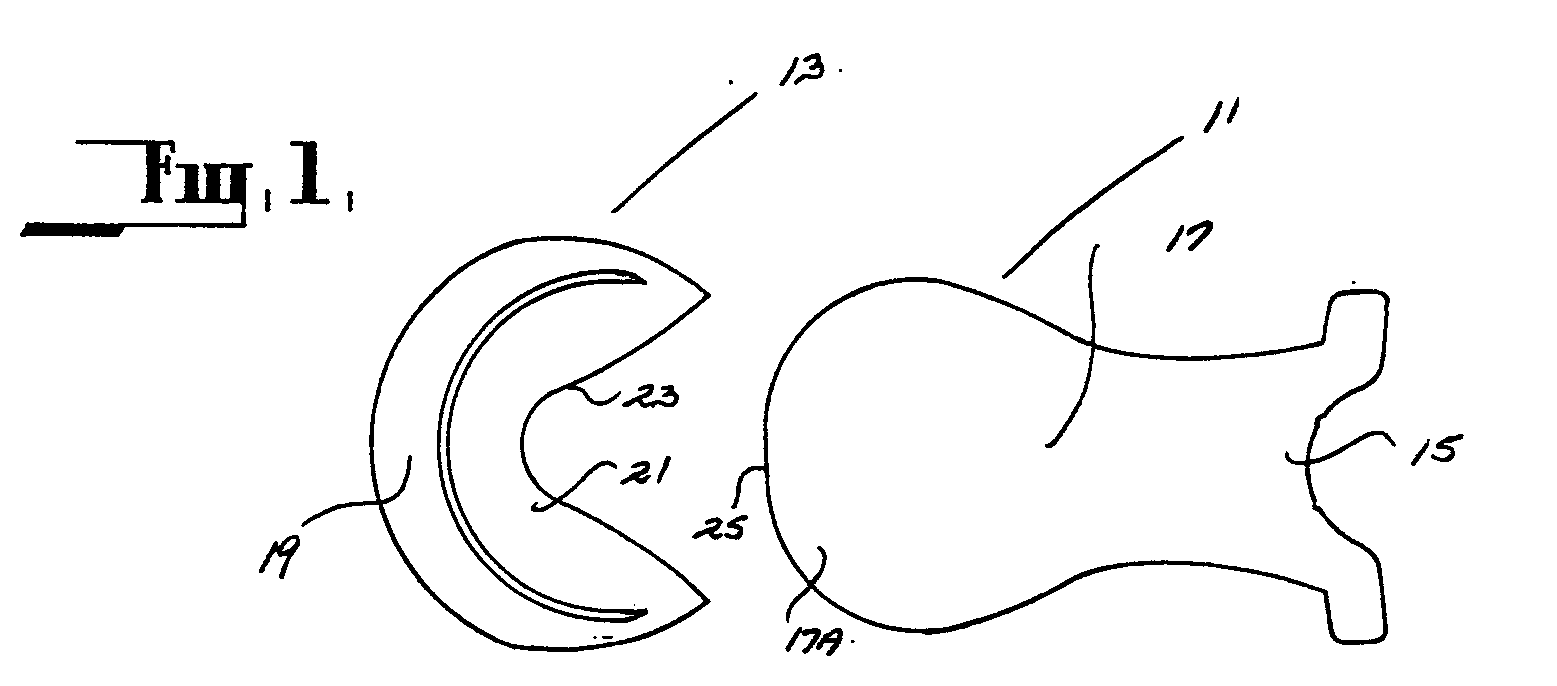

Fig. 1 is a plan view of the two moulded members;

Fig. 2 is a plan view of the cantle member in position for construction of a large

saddle; and

Fig. 3 is a plan view of the cantle member in position for the construction of a

small saddle.

[0006] In the embodiment shown in the drawings a saddle tree is constructed from two moulded

members 11 and 13. The first member 11 comprising (in one piece) the pommel 15 and

seat 17 whilst the second member 13 comprises the cantle 19. The cantle 19 has an

inwardly inclined flange 21 adapted to conform with the profile of the seat 17 so

that a relatively smooth line can be taken from the pommel 15 across the seat 17 and

up to the cantle 19. By locating the second moulded member 13 on the rearward upper

portion 17A of the seat 17 and securing thereto, a large or long saddle tree is formed

as shown in Fig. 2 of the drawings. The edge 23 of the inclined flange 21 being just

within the periphery 25 of the saddle seat 17.

[0007] Using the same two moulded members one can produce a large number of different sized

saddle trees from the largest as shown in Fig. 2 to the smallest as shown in Fig.

3. In Fig. 3 of the drawings the second moulded member 13 is brought well inwardly

on the seat portion 17 thereby reducing the length between the cantle 19 and pommel

15 and secured in position. In the innermost position (Fig. 3) the maximum amount

of surplus saddle seat 17 would be freely projecting out below the raised cantle member

19. Any surplus moulding such as this is removed before further construction of the

saddle.

[0008] As will be appreciated the two separate moulds and matching cantle-seat profiles

enables many different length of saddles to be formed. The standardising of production

procedures and components enabling less stock to be carried to meet a wide range

of customer requirements.

1. An improved saddle tree wherein the saddle tree is formed from two moulded members

(11, 13), first said member (11) comprising the pommel (15) and seat (17) of a saddle

and the second (13) of said members comprising the cantle (19), said cantle member

adapted to be secured to the seat (17) of the saddle in a pre-selected position thereby

governing the size of the saddle and distance between the pommel (15).