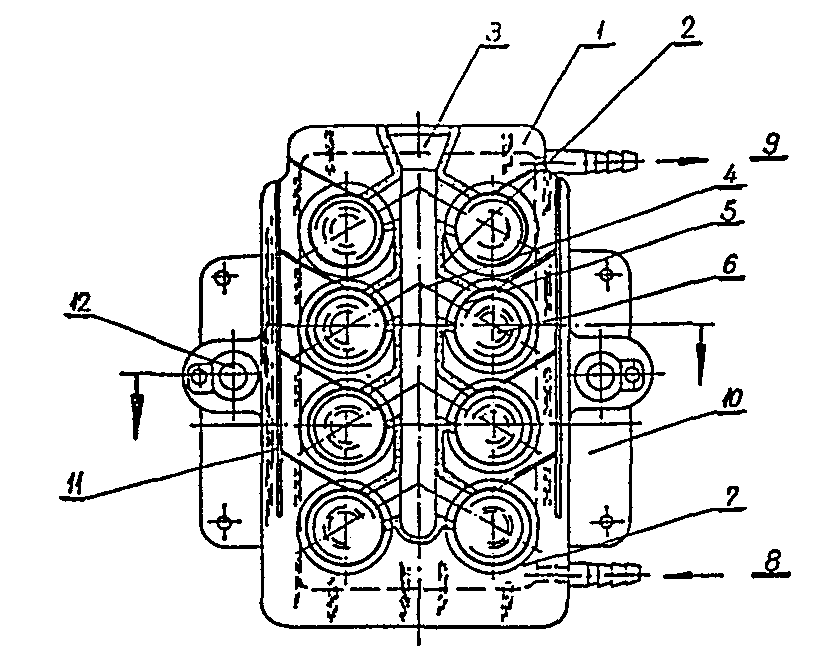

(57) The subject of this invention is production of permanent metal moulds (1) with insert

(2) of the gating system for casting mill balls and other crushing elements.

The known method for mill balls casting are those using moulds of sand-binder mixture

which moulds can serve for a single use only. Disadvantage of such moulds is in their

lower heat conductivity which affects the structure and properties of produced balls.

To get the appropriate quality grade of balls it is necessary, apart from the high

content of alloying elements, to apply very complex thermal treatment. Authors of

this invention have solved the problem in such a way that one metal mould can serve

for repetitive use of several thousand times. With regard to thermo-physical properties

of the mould, cooling of cast balls can be very intensive owing to which the casting

process gives such structure and other ball properties that balls of high quality

can be produced even from materials having a lower content of alloying elements. The

problem of ball rising is solved by introducing an insert made from sand-binder mixture

in which way the issue of controlled metal solidification in the mould has also been

solved.

To increase the operational life of tools (metal moulds), and to make them easy replaceable,

and to lower the costs of mould amortization, authors have introduced ball crystallizers

(14) in the mould (1) as replaceable part. In this way, after sometime of mould operation,

only the crystallizers (14) are to be replaced and since all other mould parts (2-13)

are rather resistantto wear and tear their operational life will last long.

Crystallizers (14) are made from alloyed steel, suitable for water cooling, or are

made from hard copper i.e. Cu-Cd; Cu-Cr; Cu-Ag and Cu-Be to which the alloying elements

are added in small quantities which do not affect heat conductivity of copper but

on the contrary increase its hardness.

|

|