(57) The object of the invention is to provide saw blades having abrasive cutter segments

which will wear non-uniformly so as to provide a concave wear surface and to thereby

minimize blade path deviation, i.e. lateral vibration of the saw blade.

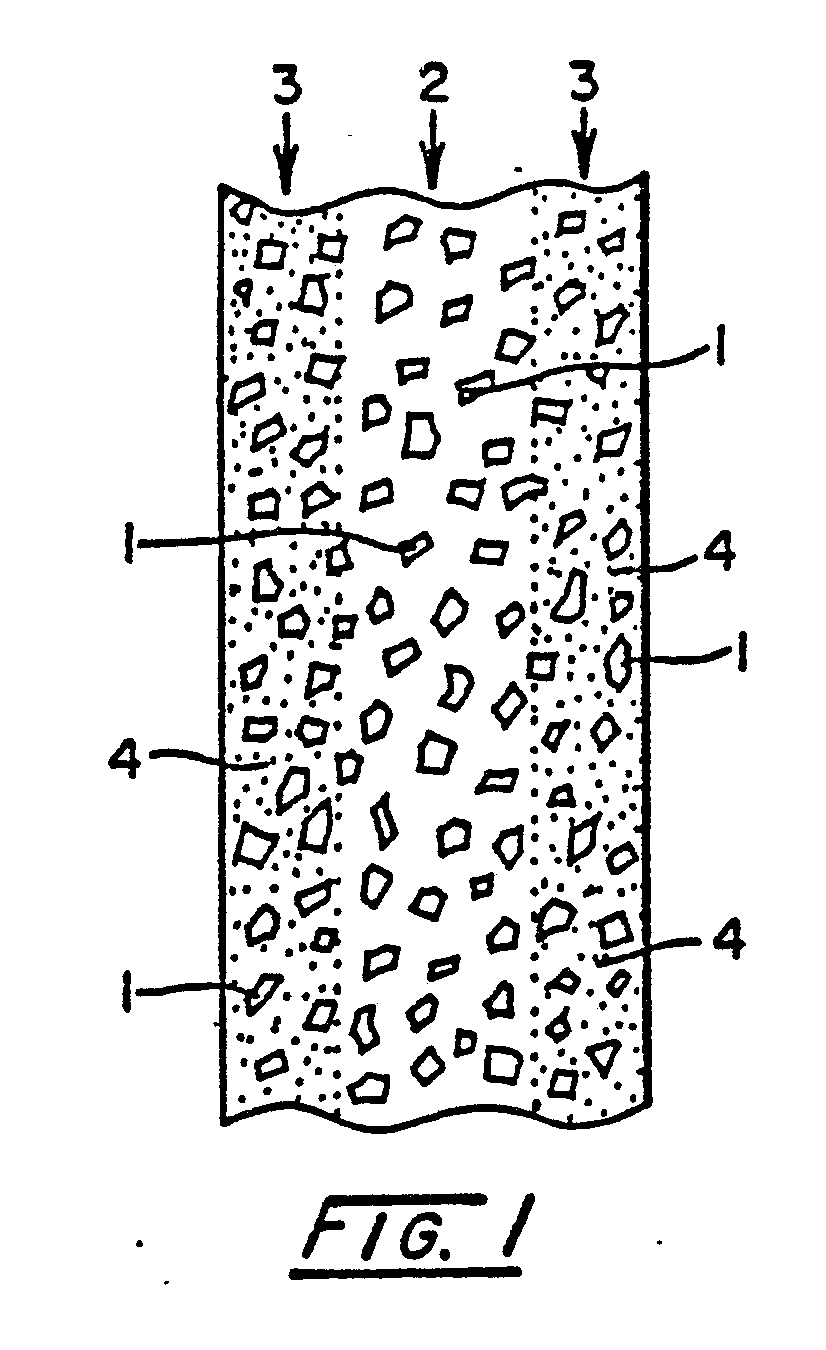

Figure 2 illustrates a preferred embodiment of a cutting segment for use on saw blades

for cutting granite, marble, filled concrete and other hard materials. As can be seen,

the concentration of diamond cutting elements (1) in the centre section (2) is preferably

about the same as the concentration of diamond cutting elements (1) in the side sections

or matrices (3). It should be appreciated, however, that a larger or smaller concentration

of diamond cutting elements (1) can be employed in the centre section (2) without

departing from the spirit or intended scope of the invention. For example, it is expected

that in some applications it may be desirable that the concentration of diamond cutting

elements (1) in the centre section (2) be greater than the concentration of diamond

cutting elements (1) in the side sections (3). The most important consideration in

the practice of the invention is that a non-uniform cutting rate be achieved by including

an effective amount of abrasion-resistant particles (4) in side sections (3). Saw

blade segments manufactured with abrasion resistant particles (4) in side sections

(3) will exhibit concave wear and will form a ridge on stone workpiece (5) as shown

in Figure 2. It is the presence of this ridge which minimize the ability of the saw

blade to deviate from its cutting path.

Any suitable particles may be utilized as the abrasion-resistant particles (4). However,

it has been found that diamond, CBN and tungsten carbide particles are particularly

effective.

In general, the abrasion-resistant particles (4) should be less than about 80 mesh.

Of course, the optimum mesh size for a particular application can be determined without

undue experimentation. The concentration of abrasion-resistant particles can also

vary depending upon the particular application, but a concentration of from about

0.10 to about 0.35 carats per cubic centimeter has been found to be effective.

|

|