|

(11) | EP 0 418 303 B1 |

| (12) | EUROPEAN PATENT SPECIFICATION |

|

|

| (54) |

GUIDE VANE FOR AN AXIAL FAN LEITSCHAUFEL FÜR AXIALGEBLÄSE AUBE DIRECTRICE POUR SOUFFLANTE AXIALE |

|

|

|||||||||||||||||||||||||||||||

| Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). |

[0002] When a gas passes through a fan the gas is deflected by the impeller rotor blades and a pressure increase is obtained across the impeller. However, the deflection means that the gas flow velocity has a rotation component after passage through the impeller. This rotation component forms a rotation energy which is often lost in the continued gas transport downstream the fan.

[0003] It is known, e.g. through SE-B-94040, to arrange a ring of guide vanes downstream the impeller to make use of this rotation energy and then raise the pressure increase of the fan as well as its efficiency. The rotation energy of the gas flow after the impeller is thus converted into a static pressure increase on passing over the guide vanes. This conversion is not free of losses, and to minimize the losses it is essential that the inlet angle of the guide vanes substantially coincides with the direction of gas flow leaving the impeller. If the inlet side of the guide vanes is not adapted to the direction of the impinging gas, a strong release of the flow is obtained at the guide vane, with large energy losses and acompanying decrease of the fan efficiency as a result. The guide vanes are also implemented so that the gas on the outlet side is given a substantially axial direction.

[0004] It has been found that the magnitude of the rotation component varies in radial direction, which means that the angle which the flow direction forms with the central axis varies with the radius. The flow is very complex, and secondary effects result in that the rotation after the fan blades will be larger at the root and top of the blades. At the root of blades, i.e. att the point of attachment of the blades to the hub, the gas flow is given an increased rotation by back flow in gaps and by the rotation of the hub, and at the top of the blades there is an increased rotation as a result of back flow which lowers the axial component. In addition, it should be noted that the exterior limiting surface, e.g. the wall of a flow duct or the like, does not only retard the tangential movement component but also the axial one. Taken together this gives the unexpected radial variation of the flow direction illustrated in Figure 1.

[0005] Figure 1 thus illustrates the result of measurements made with an axial fan. As will be seen, the flow direction angle towards the central axis is greater at the top and root of the blade, and the angle passes through a minimum value therebetween. The exact appearance of the graph is affected by such parameters as the blade angles on the impeller and the selected operating point in the corresponding fan diagram (pressure flow diagram), but the shape of the graph is qualitively the same, with a minimum between the positions of the blade root and top.

[0006] In attempts to adapt the inlet angle of the guide vane to the rotation component, which varies radially, guide vanes have been produced with varying curvature, which requires a very complicated manufacturing technique, however.

[0007] Guide vanes have also been made with an oblique edge between the inner and outer longitudinal edges of the guide vane, so that the arcuate length of the guide vane along the inner edge is longer than the arcuate length along the radially outer edge. For a constant curvature of the guide vane there is thus obtained a greater inlet angle at the radially inward portion of the guide vane than at its radially outward portion.

[0008] The object of the present invention is to provide a new guide vane, starting from the above-mentioned knowledge of the radial variation of the rotation, which vane is adapted on its inlet side to the direction of the impinging gas in a considerably improved way along the entire radial extension of the guide vane, while the guide vane is simple and cheap to manufacture.

[0009] This object is achieved with a guide vane of the kind described in the introduction and with the characterizing features stated in claim 1.

[0010] By giving the edge of the vane portion facing towards the axial rotor a configuration substantially following the variation of the rotation illustrated in Figure 1, the vane can be produced with single curvature and simultaneously obtains excellent adaption of the inlet angle to the direction of the impinging gas at every point.

[0011] With the guide vane in accordance with the invention, improvements of the fan efficiency up to 20% can be obtained compared with guide vanes generally available on the market.

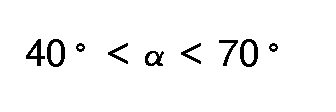

[0012] In accordance with an advantageous embodiment of the inventive guide vane, the inlet angle ₁ at the radially inward portion or root portion meets the condition:

preferably

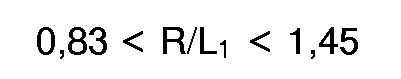

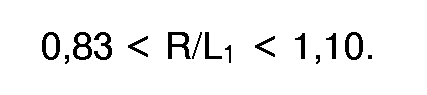

according to another advantageous embodiment of the inventive guide vane having a constant radius of curvature, the ratio between the radius of curvature R and the length L₁ of the radially inward edge of the guide vane meets the condition:

preferably

[0013] Optimization of the guide vane configuration to the selected operating point in the area in the pressure-flow diagram which is of interest is thus enabled.

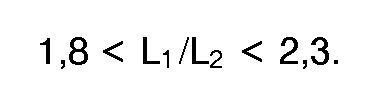

[0014] According to a still further advantageous embodiment of the inventive guide vane, the relationship between the length L₁ of the radially inward edge of the guide vane and the length L₂ of the guide vane at the level of the concaveness meets the condition:

and the concaveness level is given by the condition:

preferably

where H denotes the height for the concaveness position from the radially inward edge and H₂ the total height of the guide vane.

[0015] The inlet angle of the guide vane at the vane top must be related, e.g. to the inlet angle at the guide vane root, and according to another advantageous embodiment of the inventive guide vane this relationship is given by the condition:

where L₃ and L₁ denote the lengths of the radially outer and inner edges of the guide vane.

[0016] If the above indicated limits of the different parameters determining the configuration of the guide vane are exceeded, disturbances of different kinds occur, e.g. separation of the gas flow from the guide vane with energy losses as a result.

[0017] Embodiments of the guide vane in accordance with the invention, selected as examples, will now be described in more detail in connection with figures 2-5.

[0018] Figure 1 illustrates the radial variation of the angle between the flow direction and the central axis from the blade root to the blade top.

[0019] Figure 2 illustrates an axial fan with guide vanes arranged downstream in accordance with the invention.

[0021] Figure 4 illustrates the guide vane of Figure 3 with constant curvature, and

Figure 5 illustrates an alternative embodiment of the guide vane in accordance with the invention, also extended in a plane.

[0022] In Figure 2 there is illustrated an axial fan 2, installed in a duct 4, with the air flow direction indicated by the arrow q. Downstream the fan and at a given distance from it a ring of guide vanes 6 is mounted, the radial extension of the guide vanes substantially corresponding to that of the fan blades 8. As will be particularly seen from the vane 6', the vanes have a substantially axial outlet angle while the inlet angle forms a given angle to the central axis of the fan.

[0023] In Figure 3 there is illustrated a preferred embodiment of a guide vane 6, extended in a plane. The end portion of the guide vane 6 which is intended to face towards the fan has an edge 10 with a parabola like shape so that between the inner and outer longitudinal edges 12 and 14 of the guide vane 6 there is obtained a concaveness with a shorter lenth L₂ along the vane than said edges L₁ and L₃. The vane 6 has a stright trailing edge 16.

[0024] The height of the concaveness from the inner longitudinal edge 12 is denoted by H₁ and the total height of the vane by H₂. The position of the concaveness is determined by the condition:

preferably

[0025] When the guide vane of Figure 3 is given a constant curvature with a radius of curvature according to Figure 4, there is obtained a greater inlet angle in relation to the central axis at the inner portion of the guide vane, which will be at the level of the blade root, that at the outer portion of the vane 6, which will be at the level of the vane top, since the inner longitudinal edge 12 is longer than the outer longitudinal edge 14, see Figure 3. In the intermediate concaveness portion, the inlet angle will be still less, and thus there is achieved in a simple way a radial variation in the inlet angle which agrees with the radial variation of the gas flow rotation component, as discussed above.

[0026] For

there are obtained the ratios between the inlet angles at the outer and inner portions of the vane, which are well suited to practical applications.

[0028] To enable optimization of the guide vane at different operating points in the pressure-flow diagram, i.e. both for large flow and high pressure, the radius of curvature R, see Figure 4, and L₁ must meet the condition:

preferably

[0029] The ratio between the radii R₁ and R₂ from the central axis 18 of the fan to the inner edge 12 of the guide vane and the outer edge 14, respectively, meets the condition:

preferably

[0031] In addition, R₁ corresponds to the radius of the impeller hub, while the radius R₂ corresponds to the radius in the flow duct 4 in question, which also substantially agrees with the radius of the blade wheel, cf. Figure 2.

[0032] In Figure 5 there is illustrated an alternative embodiment of a guide vane in accordance with the invention, the edge intended to face towards the fan being formed by a polygonal train of three sides 20, 22, 24. The side 22 will then form the intermediate concaveness portion. It should be noted that the concaveness portion 22 is displaced closer to the outer edge 14, compared with the inner edge 12. This vane is also curved with a constant radius of curvature, as illustrated in Figure 4. This is a simple guide vane configuration, which gives a considerable increase in efficiency compared with previous embodiments with a monotonously extending oblique edge, as indicated by the dashed line 26 in the figure.

1. Guide vane (6,6') for an axial fan (2), characterized in that in the portion facing towards the fan a concaveness is formed between the radially

outward and inward portions of the guide vane (14 and 12, respectively), such that

the arc length in a plane parallel to the axis of the fan along the single curved

guide vane at the level of the deepest part of the concaveness (L₂) is shorter than

the arc lengths in said plane at said outward and inward portions (L₃ and L₁, respectively).

2. Guide vane as claimed in claim 1, characterized in that the edge (10) of the end portion facing towards the fan has a continous concave

shape.

3. Guide vane as claimed in claim 2, characterized in that the edge (10) has a parabola-like shape.

4. Guide vane as claimed in claim 1, characterized in that the edge of the end portion facing towards the fan has the shape of a polygonal

train (20,22,24).

5. Guide vane as claimed in claim 4, characterized in that the edge of the end portion facing towards the fan has the form of a trilateral

polygonal train (20,22,24).

6. Guide vane as claimed in anyone of claims 2-5, characterized in that the ratio between the length (L₁) of the radially inward edge of the guide

vane and the length (L₂) of the guide vane at the level of the web meets the condition:

7. Guide vane as claimed in any one of claims 1-6, characterized in that the inlet angle (α) at the root portion of the guide vane meets the condition

preferably

preferably

8. Guide vane as claimed in any one of claims 1-7, characterized in that the single-curved guide vane has a constant radius of curvature (R).

9. Guide vane as claimed in claim 8, characterized in that the ratio between the radius of curvature (R) and the length (L₁) of the radially

inward edge of the guide vane meets the condition

preferably

preferably

10. Guide vane as claimed in any one of claims 2-9, characterized in that the ratio between the height (H₁) of the position of the web from the radially

inward edge and the total height (H₂) of the guide vane meets the condition:

preferably

preferably

11. Guide vane as claimed in any one of claims 2-10, characterized in that the ratio between the lengths (L₃) and (L₁) of the radially outward and inward

edges respectively of the guide vane meets the condition:

12. Guide vane as claimed in any one of claims 1-11, characterized in that the ratio between the radii (R₁) and (R₂) from the fan axis to the outer and

inner edges of the guide vane meets the condition:

preferably

preferably

1. Leitschaufel (6,6') für ein Axialgebläserad (2), dadurch gekennzeichnet, das in dem

dem Gebläserad zugewanden Abschnitt eine Konkavität zwischen dem radial äußeren und

dem radial inneren Abschnitt der Leitschaufel (14 bzw. 12) ausgebildet ist, so daß

die Bogenlänge in einer Ebene parallel zu der Achse des Gehläserades entlang der konstant

gekrümmten Leitschaufel in Höhe des tiefsten Teiles der Konkavität (L₂) kürzer ist

als die Bogenlängen in einer solchen Ebene an dem äußeren und dem inneren Abschnitt

(L₃ bzw, L₁).

2. Leitschaufel nach Anspruch 1, dadurch gekennzeichnet, daß die Kante (10) des dem Gebläserad

zugewanden Endabschnittes eine kontinuierlich konkave Form aufweist.

3. Leitschaufel nach Anspruch 2, dadurch gekennzeichnet, daß die Kante (10) eine parabolartige

Form hat.

4. Leitschaufel nach Anspruch 1, dadurch gekennzeichnet, daß die Kante des dem Gebläserad

zugewanden Endabschnittes die Form eines Polygonzuges (20,22,24) aufweist.

5. Leitschaufel nach Anspruch 4, dadurch gekennzeichnet, daß die Kante des dem Gebläserad

zugewanden Endabschnittes die Form eines dreiseitigen Polygonzuges (20,22,24) aufweist.

6. Leitschaufel nach einem der Ansprüche 2-5, dadurch gekennzeichnet, daß das Verhältnis

zwischen der Länge (L₁) der radial inneren Kante der Leitschaufel und der Länge (L₂)

der Leitschaufel in Höhe des Halses die Bedingung erfüllt:

7. Leitschaufel nach einem der Ansprüche 1-6, dadurch gekennzeichnet, daß der Eintrittswinkel

(α) an dem Fußabschnitt der Leitschaufel die Bedingung erfüllt:

vorzugsweise

vorzugsweise

8. Leitschaufel nach einem der Ansprüche 1-7, dadurch gekennzeichnet, daß die einzelgekrümmte

Leitschaufel einen konstanten Krümmungsradius (R) aufweist.

9. Leitschaufel nach Anspruch 8, dadurch gekennzeichnet, daß das Verhältnis zwischen

dem Krümmungsradius (R) und der Länge (L₁) der radial inneren Kante der Leitschaufel

die Bedingung erfüllt:

vorzugsweise

vorzugsweise

10. Leitschaufel nach einem der Ansprüche 2-9, dadurch gekennzeichnet, daß das Verhältnis

zwischen der Höhe (H₁) der Stelle des Halses von dar radial inneren Kante zu der Gesamthöhe

(H₂) der Leitschaufel die Bedingung erfüllt:

vorzugsweise

vorzugsweise

11. Leitschaufel nach einem der Ansprüche 2-10, dadurch gekennzeichnet, daß das Verhältnis

zwischen den Längen (L₃) und (L₁) der radial äußeren bzw. inneren Kante der Leitschaufel

die Bedingung erfüllt:

12. Leitschaufel nach einem der Ansprüche 1-11, dadurch gekennzeichnet, daß das Verhältnis

zwischen den Radien (R₁) und (R₂) von der Gebläseradachse zu der äußern bzw. inneren

Kante der Leitschaufel die Bedingung erfüllt:

vorzugsweise

vorzugsweise

1. Aube directrice (6, 6') pour ventilateur axial (2) caractérisée en ce que la partie

dirigée vers le ventilateur est formée d'une concavité située entre les parties radialement

extérieure et intérieure de l'aube directrice (14 et 12 respectivement) de telle sorte

que la longueur d'arc dans un plan parallèle à l'axe du ventilateur le long de la

vanne directrice à incurvation unique au niveau de la partie la plus profonde de la

concavité (L₂) est plus courte que la longueur d'arc située dans ledit plan au niveau

desdites parties extérieure et intérieure (L₃ et L₁, respectivement).

2. Aube directrice selon la revendication 1, caractérisée en ce que le bord (10) de la

partie formant extrémité dirigée vers le ventilateur a une forme concave continue.

3. Aube directrice selon la revendication 2 caractérisée en ce que le bord (10) a une

forme analogue à une parabole.

4. Aube directrice selon la revendication 1, caractérisée en ce que le bord de la partie

formant extrémité dirigée vers le ventilateur a la forme d'une traînée polygonale

(20, 22, 24).

5. Aube directrice selon la revendication 4, caractérisée en ce que le bord de la partie

formant extrémité dirigée vers le ventilateur a la forme d'une traînée polygonale

à trois côtés (20, 22, 24).

6. Aube directrice selon l'une quelconque des revendications 2 à 5, caractérisée en ce

que le rapport entre la longueur (L₁) du bord radialement intérieur de l'aube directrice

et la longueur (L₂) de l'aube directrice au niveau de l'âme satisfait la condition:

7. Aube directrice selon l'une quelconque des revendications 1 à 6, caractérisée en ce

que l'angle d'entrée (α) au niveau de la partie formant racine de l'aube directrice

satisfait à la condition:

et de préférence

et de préférence

8. Aube directrice selon l'une quelconque des revendications 1 à 7, caractérisée en ce

que l'aube directrice ayant une courbure unique a un rayon de courbure constant (R).

9. Aube directrice selon la revendication 8, caractérisée en ce que le rapport entre

le rayon de courbure (R) et la longueur (L₁) du bord radialement intérieur de l'aube

directrice satisfait la condition suivante

et de préférence

et de préférence

10. Aube directrice selon l'une quelconque des revendications 2 à 9, caractérisée en ce

que le rapport entre la hauteur (H₁) de la position de l'âme à partir du bord radialement

intérieur et la hauteur totale (H₂) de l'aube directrice satisfait la condition suivante:

et de préférence

et de préférence

11. Aube directrice selon l'une quelconque des revendications 2 à 10, caractérisée en

ce que le rapport entre les longueurs (L₃) et (L₁) des bords radialement extérieur

et intérieur respectivement de l'aube directrice satisfait la condition:

12. Aube directrice selon l'une quelconque des revendications 1 à 11, caractérisée en

ce que le rapport entre les rayon (R₁) et (R₂) à partir de l'axe du ventilateur vers

les bords extérieur et intérieur de l'aube directrice satisfait la condition suivante:

et de préférence

et de préférence