|

(11) | EP 0 491 439 B1 |

| (12) | EUROPEAN PATENT SPECIFICATION |

|

|

| (54) |

Gasoline composition Benzinzusammensetzung Composition d'essence |

|

|

|||||||||||||||||||||||||||

| Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). |

[0001] The present invention relates to a gasoline composition comprising a major amount of a gasoline suitable for use in spark-ignition engines and a minor amount of at least one additive.

[0002] US Patent No. 3,632,510 discloses lubricating and fuel compositions comprising a major amount of a lubricating oil and a minor proportion of an ester derivative (which includes mixed ester-metal salts) of a hydrocarbon-substituted succinic acid wherein the hydrocarbon substituent contains at least about 50 aliphatic carbon atoms and no more than about 5% olefinic linkages based on the total number of carbon-carbon covalent linkages in the substituent. Sources of the hydrocarbon substituent include substantially saturated olefin polymers, particularly polymers of monoolefins having from 2 to 30 carbon atoms. Polyisobutylene is said to be the most preferred source of hydrocarbon substituent. Alcohols said to be useful in preparing the ester derivatives include compounds of the general formula

in which R3 is hydrogen; aryl; lower alkyl such as ethyl, propyl, tert-butyl, pentyl, etc.; or aralkyl; n is 0 to about 150; and R1 and R2 are lower alkylene of up to 8 carbon atoms. When added to fuels, the ester derivatives are said to promote fuel system cleanliness by preventing the formation of deposits in fuel tanks, fuel lines, carburetors, fuel injection devices, and, in many instances reduce combustion chamber deposits, spark plug fouling and exhaust valve deposits. They also function effectively as anti-screen clogging agents.

[0003] US Patent No. 4,846,848 discloses compositions containing a minor amount of a polyalphaolefin having a viscosity at 100 °C from 2 to 20 centistokes (2 x 10-s to 2 x 10-5 m2/s), and optionally also an aliphatic polyamine, an alkali or alkaline earth metal salt of a succinic acid derivative as flame speed improver, and/or a polyolefin. The succinic acid derivative is described either as having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 20 to 200 carbon atoms, or as having as a substituent on one of its alpha-carbon atoms an unsubstituted or substituted hydrocarbon group having from 20 to 200 carbon atoms which is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure. The salts of the succinic acid derivative may be monobasic salts with the remaining carboxyl group aminated or esterified. No mention is made, however, of suitable amines or alcohols for use in amination and esterification respectively. The preferred salts are stated to be the dibasic salts.

[0004] UK Patent Application Publication No. 2,177,418A(Appiicant's ref: K6240 GBR) discloses a gasoline composition comprising a major amount of a gasoline suitable for use in spark-ignition engines, and a minor amount of an alkali metal or alkaline earth metal salt of a succinic acid derivative as flame speed improver having as substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 20 to 200 carbon atoms or of a succinic acid derivative having as a substituent on one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 20 to 200 carbon atoms which is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure. Salts of the succinic acid derivative can be monobasic with the remaining carboxyl group aminated or esterified. No mention is made, however, of suitable amines or alcohols for use in amination or esterification respectively. The preferred salts are stated to be the dibasic salts.

[0005] UK Patent Specification No. 1,306,233 discloses compositions for use in fuels comprising an oil-soluble carboxylic dispersant and a thermally stable, relatively non-volatile petroleum fraction. The carboxylic dispersant is a carboxylic acid or an anhydride, ester, metal salt or acylated nitrogen derivative thereof. Substantially saturated aliphatic hydrocarbon-substituted succinic acids and anhydrides are especially preferred as dispersants.

[0006] It has now been found that alkali metal salts of certain succinic acid derivatives are useful as spark-aiders (flame speed improvers) and compared with spark-aiders already known in the art they have the advantage of being less viscous and less prone to agglomeration, the latter being a particular problem as it leads to valve-sticking.

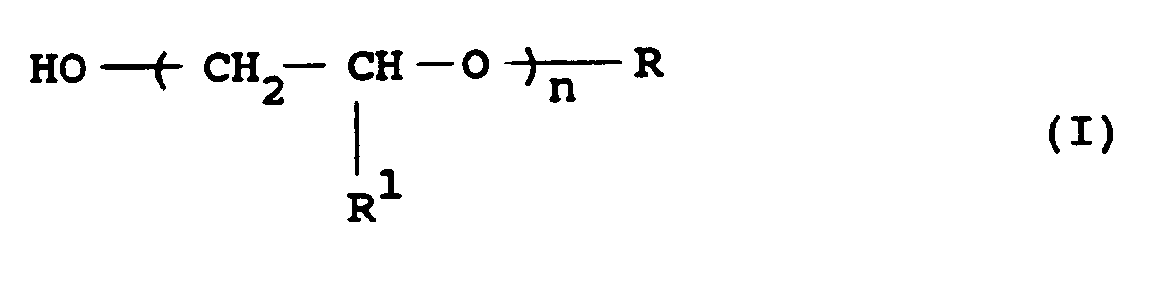

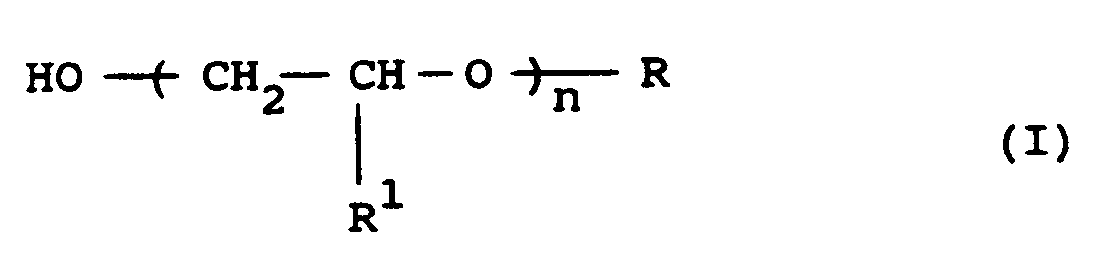

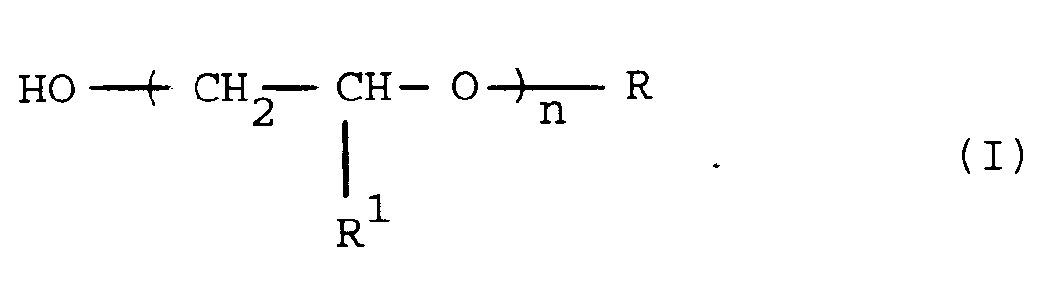

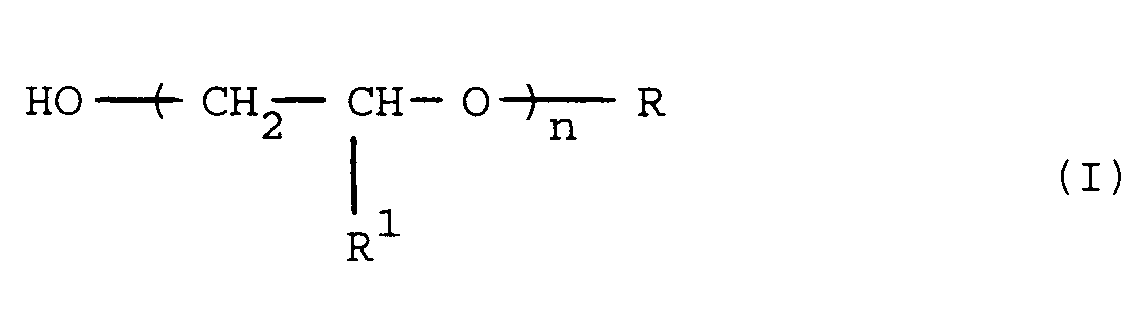

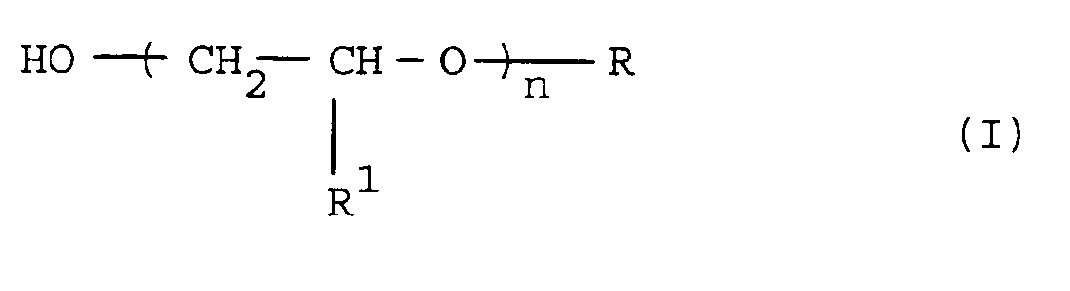

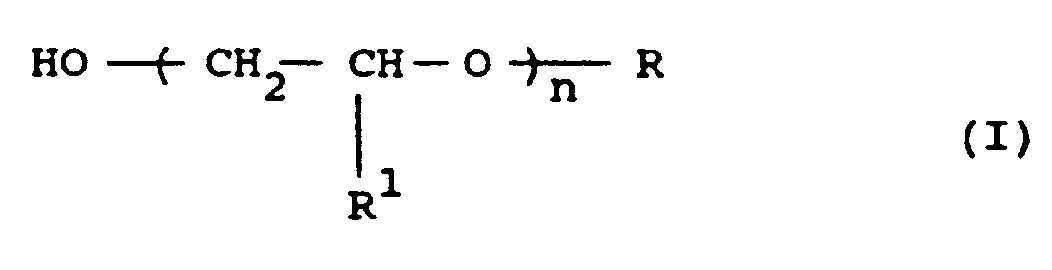

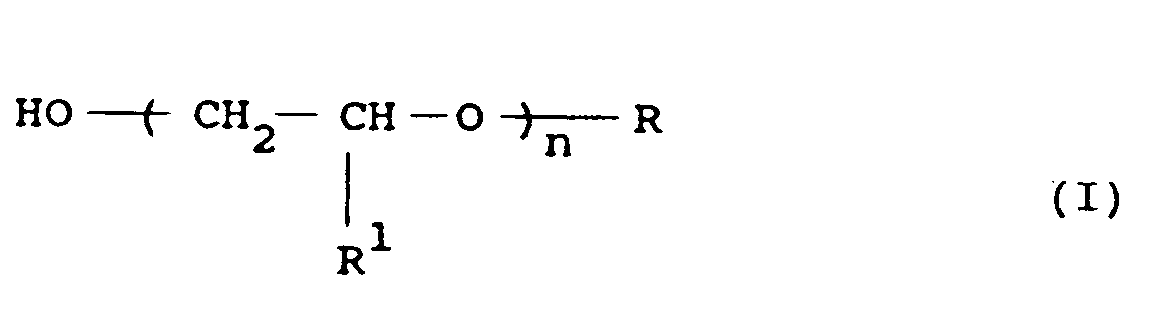

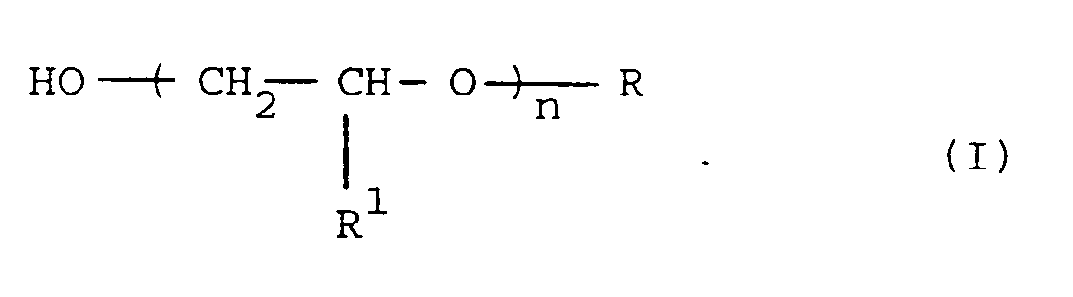

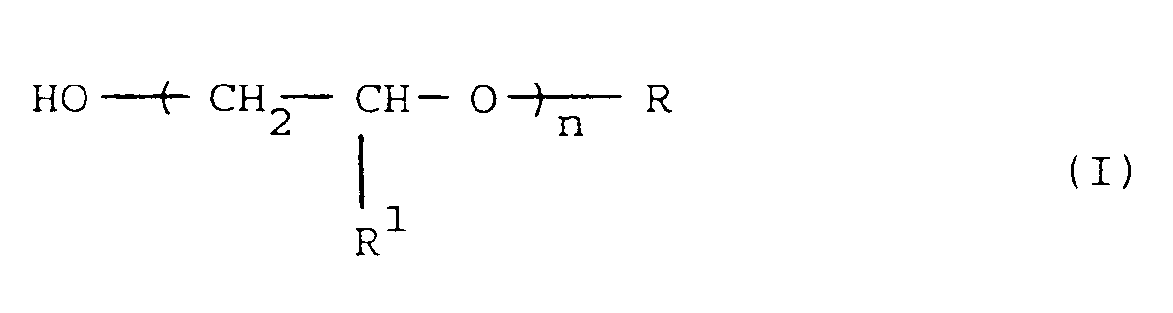

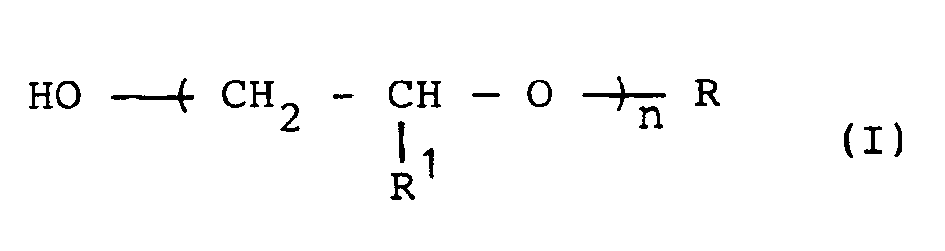

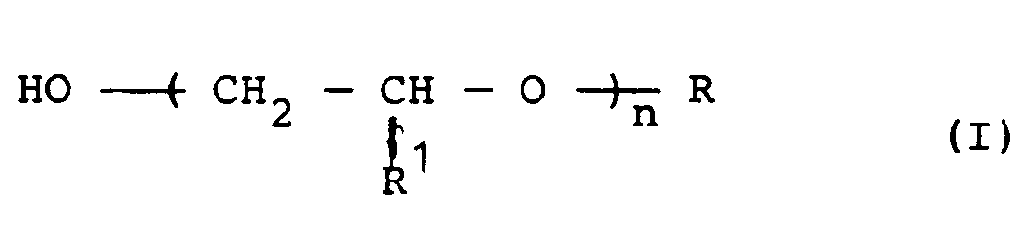

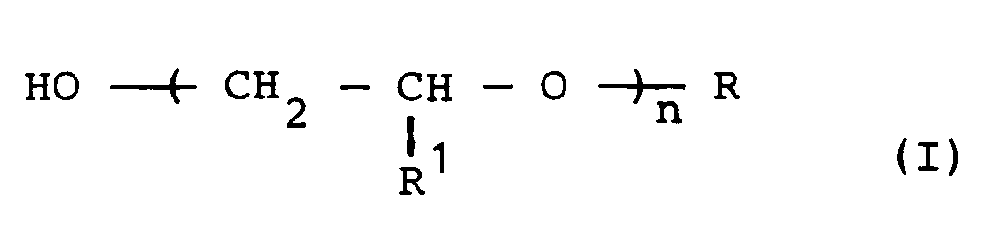

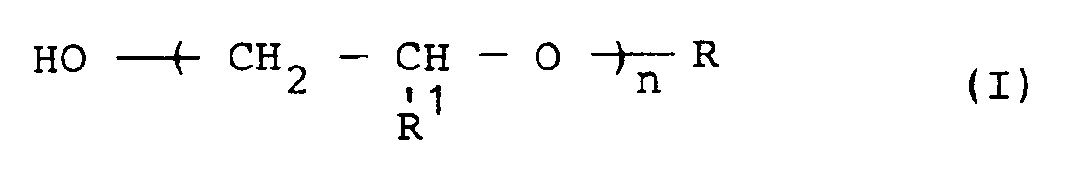

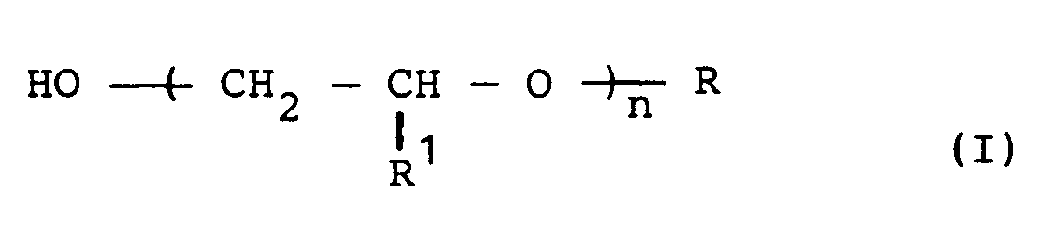

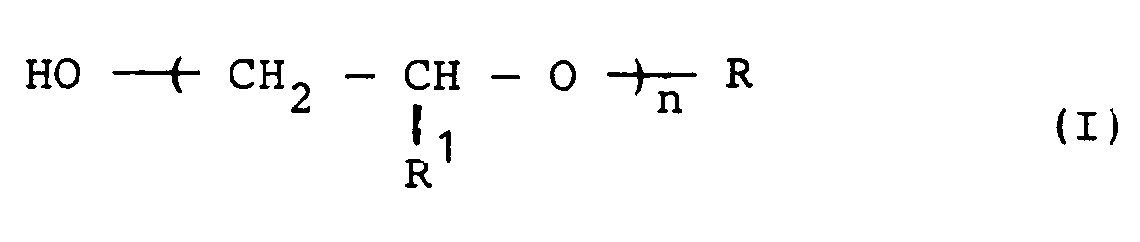

[0007] According to the present invention, there is therefore provided a gasoline composition comprising a major amount of a gasoline suitable for use in spark-ignition engines and a minor amount of an alkali metal salt of a partial ester of an alkyl polyether alcohol of the general formula

in which n is an integer from 4 to 25, R represents a CS-C2o alkyl group and each R1 independently represents a hydrogen atom or a Cl-Clo alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

[0008] The present invention further provides a method of operating a spark-ignition internal combustion engine which comprises introducing to said engine a gasoline composition as defined above.

[0009] The alkali metal salt of the partial ester is preferably the sodium, or especially the potassium, salt.

[0011] Preferably n is an integer from 4 to 20, more preferably from 4 to 15 and is especially 5 or 6.

[0012] Preferably R contains at least 6 carbon atoms, preferably at least 7 carbon atoms. Advantageously R represents a C9-C15, or more preferably a C12-C15, alkyl group.

[0013] Preferably each R1 independently represents a hydrogen atom or a C1-C5 alkyl, preferably methyl or ethyl, group.

[0014] The compounds of general formula (I) are known compounds or can be prepared by processes analogous to known processes.

[0015] The nature of the substituent(s) on at least one of the alpha-carbon atoms of the succinic acid derivative is of importance since it determines to a large extent the solubility of the alkali metal salt of the partial ester in gasoline.

[0016] The aliphatic hydrocarbon group may conveniently be derived from a polyolefin, the monomers of which have 2 to 6 carbon atoms, e.g. a polyethylene, polypropylene, polybutylene, polypentene, polyhexene or mixed polymer. Particularly preferred is an aliphatic hydrocarbon group which is derived from polyisobutylene.

[0017] Preferably the aliphatic hydrocarbon group has from 15 to 150, more preferably from 15 to 100, and advantageously from 15 to 45, carbon atoms. Aliphatic hydrocarbon groups having from 20 to 30 carbon atoms have been found to be very effective.

[0018] The aliphatic hydrocarbon group may contain substituents, e.g. one or more hydrogen atoms may be replaced by another atom, e.g. a halogen atom, or by a non-aliphatic organic group, e.g. an (un)substituted phenyl group, or a hydroxy, ether, ketone, aldehyde or ester group.

[0019] The succinic acid derivative may have more than one C15-C200 aliphatic hydrocarbon group attached to one or both alpha-carbon atoms. Preferably, the succinic acid has one C15-C200 aliphatic hydrocarbon group on one of its alpha-carbon atoms. On the other alpha-carbon atom conveniently no substituent or only a rather short hydrocarbon, for example, C1-CS group is attached. The latter group can be linked with the C15-C200 aliphatic hydrocarbon group, forming a ring structure.

[0020] The preparation of the substituted succinic acid derivatives is known in the art. In case a polyolefin is used as substituent, the substituted succinic acid derivative can conveniently be prepared by mixing the polyolefin, for example polyisobutylene, with maleic acid or maleic anhydride and passing chlorine through the mixture, yielding hydrochloric acid and polyolefin-substituted succinic acid, as described in e.g. UK Patent Specification No. 949,981.

[0021] From e.g. UK Patent Specification No. 1,483,729 it is known to prepare hydrocarbon-substituted succinic anhydride by reacting thermally a polyolefin with maleic anhydride.

[0022] The partial ester of the polyolefin-substituted succinic acid may conveniently be prepared by reacting in known manner the polyolefin-substituted succinic acid with an alkyl polyether alcohol of general formula (I), e.g. such an alcohol in which n is 5, R is a mixture of C12-C15 alkyl groups and R1 is a methyl group that is available under the trade mark "Oxilube-500" from member companies of the Royal Dutch/Shell Group. From the partial ester the corresponding alkali metal salt can conveniently be prepared by reaction with an alkali metal hydroxide such as potassium hydroxide.

[0023] The gasoline composition according to the invention may conveniently contain from 1 to 1000 ppmw, preferably 100 to 400 ppmw, of the alkali metal salt of the partial ester, most preferably to give an alkali metal, preferably potassium, concentration in the range 4 to 16 ppmw.

[0024] It will be appreciated by those skilled in the art that the presence of the alkali metal in gasoline compositions according to the invention can be expected to confer protection against valve seat recession in engines.

[0025] The gasoline composition according to the invention may also contain other additives. Thus, it can contain a lead compound as anti-knock additive and accordingly, the gasoline composition according to the invention includes both leaded and unleaded gasoline. The gasoline composition can also contain antioxidants such as phenolics, e.g. 2,6-di-tert-butylphenol, or phenylenediamines, e.g. N,N'-di-sec-butyl-p-phenylenediamine, or anti-knock additives other than lead compounds, or polyether amino additives, e.g. as described in US Patent No. 4,477,261 and European Patent Application Publication No. 151,621.

[0026] A particularly suitable additive in addition to the alkali metal salt of the partial ester for the gasoline composition according to the invention is a polyolefin derived from C2-C6 monomers. Preferably the polyolefin is polyisobutylene having from 20 to 175 carbon atoms and especially from 35 to 150 carbon atoms. The amount of polyolefin in the gasoline composition according to the invention is preferably from 100 to 1200 ppmw.

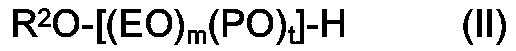

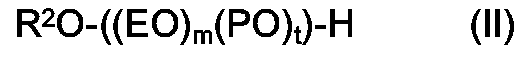

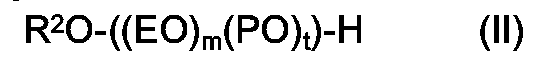

[0027] Alternatively some or all of the polyolefin derived from C2-C6 monomers may be substituted by a polyoxyalkylene glycol hemi-ether of the general formula

in which EO represents ethyleneoxy, PO represents propyleneoxy, R2 is C1-C20 alkyl and m and t represent average numbers of ethyleneoxy and propyleneoxy moieties in each hemi-ether molecule such that m/(m+t) is in the range 0 to 0.5 and t/(m+t) is in the range 0.5 to 1, having number average molecular weight (Mn) of the hemi-ether in the range 500 to 3000. Preferably in the formula II, R2 is a mixture of C12-C15 alkyl groups and the kinematic viscosity of the hemi-ether is about 80 mm2/s at 20°C according to ASTM D445, such a hemi-ether is available under the trade mark "Oxilube-949" from member companies of the Royal Dutch/Shell Group. The amount of hemi-ether in the gasoline composition according to the invention is preferably from 100 to 1200 ppmw.

[0028] Another particularly suitable additive in addition to the alkali metal salt of the partial esterfor the gasoline composition according to the invention is a C20-C150 alkyl or alkenyl group-containing polyamine. Preferably the polyamine is N-polyisobutylene-N',N'-dimethyl-1 ,3-diaminopropane. The amount of polyamine in the gasoline composition according to the invention is preferably from 5 to 200 ppmw.

[0029] A very suitable additive combination in addition to the alkali metal salt of the partial ester for the gasoline composition according to the present invention is described in United States patent specification No. 4,357,148. This additive combination comprises an oil soluble aliphatic polyamine and a hydrocarbon polymer. This additive combination reduces the octane requirement increase (ORI). The ORI-reduction is associated with the prevention of deposit formation in the combustion chamber and adjacent surfaces in spark-ignition engines and/orwith the removal of such deposits therefrom. Although various types of polyamines and various types of polymers can be used, it is preferred to use a polyolefin, the monomers of which have 2 to 6 carbon atoms, in combination with a C20-150 alkyl or alkenyl group-containing polyamine. Therefore, the gasoline composition according to the present invention preferably contains such a combination. A very advantageous species of the above polyolefin is polyisobutylene, having from 20 to 175 carbon atoms in particular polyisobutylene having from 35 to 150 carbon atoms. The polyamine used is preferably N-polyisobutylene-N',N'-dimethyl-1,3- diaminopropane. The contents of the polyolefin and of the alkyl or alkenyl group-containing polyamine in the gasoline composition according to the present invention is preferably from 100 to 1200 ppmw and from 5 to 200 ppmw, respectively. The composition may further suitably contain a non-ionic surfactant, such as an alkylphenol or an alkyl alkoxylate. Suitable examples of such surfactants include C4-C1s-alkylphenol and C2-67alkylethoxylate or C2-6-alkylpropoxylate or mixtures thereof. The amount of the surfactant is advantageously from 10 to 1000 ppmw. The composition may still further suitably contain a detergent such as a polyolefin-substituted succinimide. Suitable examples of such detergents include the polyolefin-substituted succinimides described in EP-A-271937. The amount of detergent is advantageously from 10 to 1000 ppmw.

[0030] The gasoline composition according to the invention comprises a major amount of a gasoline (base fuel) suitable for use in spark-ignition engines. This includes hydrocarbon base fuels boiling essentially in the gasoline boiling range from 30 to 230°C. These base fuels may comprise mixtures of saturated, olefinic and aromatic hydrocarbons. They can be derived from straight-run gasoline, synthetically produced aromatic hydrocarbon mixtures, thermally or catalytically cracked hydrocarbon feedstocks, hydrocracked petroleum fractions or catalytically reformed hydrocarbons. The octane number of the base fuel is not critical and will generally be above 65. In the gasoline, hydrocarbons can be replaced up to substantial amounts by alcohols, ethers, ketones or esters. Naturally, the base fuels are suitably substantially free of water since water may impede a smooth combustion.

[0031] The alkali metal salts of the partial esters can be added separately to the gasoline or they can be blended with other additives and added to the gasoline together. A preferred method of adding these salts to gasoline is first to prepare a concentrate of these salts and then to add this concentrate in a calculated, desired amount to the gasoline.

[0032] The present invention therefore further provides a concentrate suitable for addition to gasoline comprising a gasoline-compatible diluentwith from 20 to 50%w, calculated on the diluent, of an alkali metal salt of a partial ester of an alkyl polyether alcohol of the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a Cl-Clo alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

[0033] Suitable gasoline-compatible diluents are hydrocarbons, like heptane, alcohols or ethers, such as methanol, ethanol, propanol, 2-butoxyethanol or methyl tert-butyl ether. Preferably the diluent is an aromatic hydrocarbon solvent such as toluene, xylene, mixtures thereof or mixtures of toluene or xylene with an alcohol. Optionally, the concentrate may contain a dehazer, particularly a polyether-type ethoxylated alkylphenol-formaldehyde resin. The dehazer, if employed, is preferably present in the concentrate in an amount of from 0.01 to 1%w, calculated on the diluent.

[0034] The invention further provides for the use of an alkali metal salt of a partial ester of an alkyl polyether alcohol of the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a Cl-Clo alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure, as a spark-aider and anti-valve stick agent in a gasoline composition comprising a major portion of a gasoline suitable for use in spark-ignition engines.

Example 1

[0036] Polyisobutylene having a number average molecular weight (Mn) of 280 as determined by gel permeation chromatography and maleic anhydride were stirred together with heating up to 180°C in a nitrogen atmosphere. Chlorine was then added to the reaction mixture over a period of five hours and the reaction mixture maintained at 180°C for a further four hours. The molar ratio of polyisobutylene/maleic anhydride/chlorine in the reaction mixture was 1.0/1.5/1.12. Excess maleic anhydride was then removed by distillation to yield polyisobutenyl succinic anhydride with an acid value of 5.9mmol/g.

[0037] A mixture of the polyisobutenyl succinic anhydride (100g) obtained above and 148g of an alkyl polyether alcohol of general formula (I) in which n is 5, R is a mixture of C12-Cl5 alkyl groups and R1 represents a methyl group (available under the trade mark "Oxilube-500" from member companies of the Royal Dutch/Shell Group) was then heated at 200°C for five hours at atmospheric pressure and for one hour at a pressure of 20mmHg, yielding a partial ester with an acid value of 2.1 mmol/g. After cooling, the partial ester (100g) obtained above was dissolved in xylene (50g) and the resulting solution mixed with a solution of potassium hydroxide in methanol (8.5g of 83%w potassium hydroxide dissolved in 21.2g of methanol). The reaction mixture was heated to 65°C for a period of three hours, at the end of which time the reaction mixture was filtered and the filtrate retained. Purification of the filtrate yielded the desired salt (potassium content, 4.4%m).

Example 2

[0038] A mixture of polyisobutylene of number average molecular weight (Mn) 340 as determined by gel permeation chromatography (280g) and maleic anhydride (196g) was heated for sixteen hours at 200°C, at the end of which the excess maleic anhydride was distilled off to yield polyisobutenyl succinic anhydride with an acid value of 5.3 mmol/g.

[0039] A mixture of the polyisobutenyl succinic anhydride (303.9g) obtained above and 405.5g of the alkyl polyether alcohol of general formula (I) referred to in Example 1 was heated at 200°C for three and a half hours at atmospheric pressure and for one hour at a pressure of 20mmHg. The product obtained, a partial ester, was found to have an acid value of 1.04 mmol/g. Reaction of the partial ester (681g) obtained above dissolved in xylene (500ml) with a solution of potassium hydroxide in methanol (8.5g of 83%w potassium hydroxide dissolved in 21.2g methanol) at 65°C for three hours, followed by filtration and then purification yielded the desired salt with a potassium content of 4.0%m.

Example 3

[0040] By a process analogous to that described in Example 2, a potassium salt of a partial ester of an alkyl polyether alcohol of general formula (I) in which n is 5, R is a mixture of C9-C11 alkyl groups and R1 represents a hydrogen atom, of number average molecular weight (Mn) 380 as determined by gel permeation chromatography (available under the trade mark "Dobanol 91-5" from member companies of the Royal Dutch/Shell Group) and polyisobutenyl succinic acid was prepared using the above alkyl polyether alcohol in place of the alkyl polyether alcohol referred to in Example 2.

Example 4

[0041] By a process analogous to that described in Example 2, a potassium salt of a partial ester of a condensate of a blend of C12-Cl5 alkanols, propylene oxide and ethylene oxide in molar ratio alkanol: propylene oxide: ethylene oxide of 1: 4.2: 5.6 (density at 20°C ASTM D1298 of 0.98; viscosity index ASTM D2270 of 186; number average molecular weight (Mn) of 700; available under the trade mark "Oxilube-501" from member companies of the Royal Dutch/Shell Group) and polyisobutenyl succinic acid was prepared using the above condensate in place of the alkyl polyether alcohol referred to in Example 2.

Example 5

[0042] A mixture of polyisobutylene of number average molecular weight (Mn) 353 as determined by gel permeation chromatography (45 kg) and maleic anhydride (25 kg) was heated for sixteen hours at 200°C, at the end of which the excess maleic anhydride was distilled off to yield polyisobutenyl succinic anhydride with an acid value of 4.04 mmol/g (residual maleic anhydride < 0.1%w and polyisobutylene 21.7%w).

[0043] A mixture of the polyisobutenyl succinic anhydride (35 kg) obtained above and 35.2 kg of the alkyl polyether alcohol of general formula (I) referred to in Example 1 was heated at 200°C for four and a half hours at atmospheric pressure. The product obtained, a partial ester, was found to have an acid value of 1.04 mmol/g. Reaction of the partial ester (69 kg) obtained above dissolved in xylene (30 kg) with a solution of potassium hydroxide in methanol (17 kg of 25%w solution) at 65 °C for three hours, followed by filtration and then purification yielded the desired salt with a potassium content of 2.10%w. The non volatiles concentration was 61.1%w.

Example 6

[0044] A method of predicting what might happen in a vehicle engine under certain driving conditions is to study the appearance and the viscosity characteristics of an additive package (blend) after removal of all the light components (i.e. those components boiling below 350°C). Thus, additive packages A to H shown in Table 1 were distilled to remove the light components using a rotary evaporator operated fora period of 1 hour at 140°C and 1.3 Pa and the viscosities of the remaining residues determined according to ASTM D445. The results are also shown in Table I. The additives used were: Additive I: N-polyisobutylene-N',N'-dimethyl-1,3-diaminopropane, the polyisobutylene having an average molecular weight of 1350 as determined by vapour phase osmometry; Additive II: potassium polyisobutenyl succinate, the polyisobutylene having an average molecular weight of 950 as determined by vapour phase osmometry; Additive III: polyisobutylene having a number average molecular weight of 650 as determined by gel permeation chromatography; and Additive IV: a polyoxyalkylene glycol hemi-ether of formula (II) in which R2 is a mixture of c12-c15 alkyl groups, the hemi-ether having a kinematic viscosity of about 80mm2/s at 20°C according to ASTM D445 which is available under the trade mark "Oxilube-949" from member companies of the Royal Dutch/Shell Group.

[0045] It is commonly known that the viscosity of an additive package residue and the valve-stick tendency of the additive package are directly correlated. Thus the higher the viscosity of an additive package residue, the greater the valve-stick tendency of that additive package. Table I clearly shows that the residues of additive packages C to H containing the products of Examples 1, 2 and 4 have lower viscosities in comparison with the viscosities of the residues of the prior art additive packages, Aand B. Thus it follows that additive packages C to H must also have lower valve-stick tendencies in comparison with those of additive packages A and B.

Example 7

[0046] Additive packages A, B and C were tested in the inlet valve-stick test in a Volkswagen Transporter according to the following method.

[0047] The vehicle was first run on a base fuel over a distance of 50 kilometres in order to flush out the fuel system. Then the vehicle was test-run 112 kilometres on a mixture of the base fuel and one of additive packages A, B and C. Over this distance, the vehicle experienced hot soak periods, periods of idling and maximum speeds of 24, 40 and 56 kilometres/hour in 2nd, 3rd and 4th gears respectively. During the hot soak periods, the vehicle was allowed to stand for 10 minutes with the engine switched off. Conversely, during the periods of idling, the vehicle was allowed to stand for 30 seconds with the engine switched on.

[0048] On completion of the test-run, the vehicle was parked overnight in a refrigerated trailer at a temperature of -16°C. Valve-sticking was evaluated the following morning by measuring the maximum compression pressure in each cylinder.

[0050] The results are shown in Table II from which it can be seen that the average maximum compression pressure for additive package C is higher than that for prior art additive package A having regard to both the Volkswagen Transporter and the Vauxhall Cavalier, and higher than that for prior art additive package B having regard to the Volkswagen Transporter.

Example 8

[0051] To assess the performance of spark-aiders, tests were run using a 1.3 litre Astra engine which had been modified to provide optical access to the combustion chamber of one of the cylinders. The compression ratio for the cylinder considered in the tests was 5.8:1. In each test, the engine was operated at 2000 rpm over a period of 2 hours, during which time measurements were continually taken. From the data gathered, it was possible to determine for each spark-aider tested the reduction in cyclic variation of the indicated mean effective pressures (IMEP). The tests were run on unleaded gasoline without a potassium additive and on unleaded gasoline with 2, 4 and 8 ppmw of potassium. The potassium was added as the salt of the partial ester of polyisobutylene-substituted succinic acid (the polyisobutylene having an average molecular weight of 280 as determined by gel permeation chromatography) with the alkyl polyether alcohol of formula (I) in which n is 5, R is a mixture of c12-c15 alkyl groups and R1 represents a methyl group (available under the trade mark "Oxilube-500" from member companies of the Royal Dutch/Shell Group).

Claims for the following Contracting State(s) : BE, DE, FR, GB, IT, NL

1. A gasoline composition comprising a major amount of a gasoline suitable for use

in spark-ignition engines and a minor amount of an alkali metal salt of a partial

ester of an alkyl polyether alcohol of the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

2. A gasoline composition according to claim 1, in which the alkali metal is potassium.

3. Agasoline composition according to claim 1 or claim 2, in which the aliphatic hydrocarbon

group is derived from a polyolefin, the monomers of which have 2 to 6 carbon atoms.

4. Agasoline composition according to any one of the preceding claims, in which the

aliphatic hydrocarbon group has from 15 to 45 carbon atoms.

5. A gasoline composition according to any one of the preceding claims, in which R

represents a C9-C15 alkyl group.

6. Agasoline composition according to any one of the preceding claims, which additionally

comprises minor amounts of a polyolefin derived from a C2-C6 monomer and/or a polyoxyalkylene glycol hemi-ether of the general formula

in which EO represents ethyleneoxy, PO represents propyleneoxy, R2 is C1-C20 alkyl and m and t represent average numbers of ethyleneoxy and propyleneoxy moieties in each hemi-ether molecule such that m/(m + t) is in the range 0 to 0.5 and t/(m + t) is in the range 0.5 to 1, the number average molecular weight (Mn)of the hemi-ether being from 500 to 3000, and of a C20-C150 alkyl or alkenyl group-containing polyamine.

in which EO represents ethyleneoxy, PO represents propyleneoxy, R2 is C1-C20 alkyl and m and t represent average numbers of ethyleneoxy and propyleneoxy moieties in each hemi-ether molecule such that m/(m + t) is in the range 0 to 0.5 and t/(m + t) is in the range 0.5 to 1, the number average molecular weight (Mn)of the hemi-ether being from 500 to 3000, and of a C20-C150 alkyl or alkenyl group-containing polyamine.

7. A gasoline composition according to claim 6, which contains from 100 to 1200 ppmw

of the polyolefin and/or polyoxyalkylene glycol hemi-ether and from 5 to 200 ppmw

of the alkyl or alkenyl group-containing polyamine.

8. A concentrate suitable for addition to gasoline comprising a gasoline-compatible

diluent with from 20 to 50%w, calculated on the diluent, of an alkali metal salt of

a partial ester of an alkyl polyether alcohol of the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

9. A method of operating a spark-ignition internal combustion engine which comprises

introducing to said engine a gasoline composition according to any one of claims 1

to 7.

10. Use of an alkali metal salt of a partial ester of an alkyl polyether alcohol of

the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure, as a spark-aider and anti-valve stick agent in a gasoline composition comprising a major portion of a gasoline suitable for use in spark-ignition engines.

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure, as a spark-aider and anti-valve stick agent in a gasoline composition comprising a major portion of a gasoline suitable for use in spark-ignition engines.

Claims for the following Contracting State(s) : ES

1. A process for the preparation of a gasoline composition which comprises mixing

a major amount of a gasoline suitable for use in spark-ignition engines and a minor

amount of an alkali metal salt of a partial ester of an alkyl polyether alcohol of

the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

2. A process according to claim 1, in which the alkali metal is potassium.

3. A process according to claim 1 or claim 2, in which the aliphatic hydrocarbon group

is derived from a polyolefin, the monomers of which have 2 to 6 carbon atoms.

4. A process according to any one of the preceding claims, in which the aliphatic

hydrocarbon group has from 15 to 45 carbon atoms.

5. A process according to any one of the preceding claims, in which R represents a

C9-C15 alkyl group.

6. A process according to any one of the preceding claims, which additionally comprises

mixing minor amounts of a polyolefin derived from a C2-C6 monomer and/or a polyoxyalkylene glycol hemi-ether of the general formula

in which EO represents ethyleneoxy, PO represents propyleneoxy, R2 is Cl-C20 alkyl and m and t represent average numbers of ethyleneoxy and propyleneoxy moieties in each hemi-ether molecule such that m/(m+t) is in the range 0 to 0.5 and t/(m+t) is in the range 0.5 to 1, the number average molecular weight (Mn) of the hemi-ether being from 500 to 3000, and of a C20-C150 alkyl or alkenyl group-containing polyamine.

in which EO represents ethyleneoxy, PO represents propyleneoxy, R2 is Cl-C20 alkyl and m and t represent average numbers of ethyleneoxy and propyleneoxy moieties in each hemi-ether molecule such that m/(m+t) is in the range 0 to 0.5 and t/(m+t) is in the range 0.5 to 1, the number average molecular weight (Mn) of the hemi-ether being from 500 to 3000, and of a C20-C150 alkyl or alkenyl group-containing polyamine.

7. A process according to claim 6, which comprises mixing from 100 to 1200 ppmw of

the polyolefin and/or polyoxyalkylene glycol hemi-ether and from 5 to 200 ppmw of

the alkyl or alkenyl group-containing polyamine.

8. A process for the preparation of a concentrate suitable for addition to gasoline

which comprises mixing a gasoline-compatible diluent with from 20 to 50%w, calculated

on the diluent, of an alkali metal salt of a partial ester of an alkyl polyether alcohol

of the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure.

9. A method of operating a spark-ignition internal combustion engine which comprises

introducing to said engine a gasoline composition prepared by a process according

to any one of claims 1 to 7.

10. Use of an alkali metal salt of a partial ester of an alkyl polyether alcohol of

the general formula

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure, as a spark-aider and anti-valve stick agent in a gasoline composition comprising a major portion of a gasoline suitable for use in spark-ignition engines.

in which n is an integer from 4 to 25, R represents a C6-C20 alkyl group and each R1 independently represents a hydrogen atom or a C1-C10 alkyl group, with a succinic acid derivative having as a substituent on at least one of its alpha-carbon atoms an unsubstituted or substituted aliphatic hydrocarbon group having from 15 to 200 carbon atoms which optionally is connected to the other alpha-carbon atom by means of a hydrocarbon moiety having from 1 to 6 carbon atoms, forming a ring structure, as a spark-aider and anti-valve stick agent in a gasoline composition comprising a major portion of a gasoline suitable for use in spark-ignition engines.

Patentansprüche für folgende(n) Vertragsstaat(en) : BE, DE, FR, GB, IT, NL

1. Eine Benzinzusammensetzung, die einen größeren Teil eines für den Einsatz in Vergasermotoren

geeigneten Benzins und einen kleineren Teil eines Alkalimetallsalzes eines Teilesters

eines Alkylpolyätheralkohols der allgemeinen Formel (I)

in welcher n eine ganze Zahl von 4 bis 25 ist, R eine C6-C20-Alkylgruppe ist, und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat enthält, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

in welcher n eine ganze Zahl von 4 bis 25 ist, R eine C6-C20-Alkylgruppe ist, und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat enthält, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

2. Eine Benzinzusammensetzung nach Anspruch 1, in welcher das Alkalimetall Kalium

ist.

3. Eine Benzinzusammensetzung nach Anspruch 1 oder 2, in welcher die aliphatische

Kohlenwasserstoffgruppe von einem Polyolefin abgeleitet ist, dessen Monomere 2 bis

6 Kohlenstoffatome aufweisen.

4. Eine Benzinzusammensetzung nach einem der vorstehenden Ansprüche, in welcher die

aliphatische Kohlenwasserstoffgruppe 15 bis 45 Kohlenstoffatome aufweist.

5. Eine Benzinzusammensetzung nach einem der vorstehenden Ansprüche, in welcher R

eine C9-C15-Alkylgruppe ist.

6. Eine Benzinzusammensetzung nach einem dervorstehenden Ansprüche, welche zusätzlich

geringe Mengen eines Polyolefins, das von einem C2-C6-Monomer abgeleitet ist, und/oder eines Polyoxyalkylenglykol-Halbäthers der allgemeinen

Formel (11)

in welcher EO Ethylenoxy ist, PO Propylenoxy ist, R2 C1-C20-Al- kyl bedeutet und m und t durchschnittliche Zahlen von Ethylenoxy- und Propylenoxygruppen in jedem Halbäthermolekül bedeuten derart, daß m/(m+t) im Bereich von 0 bis 0,5 liegt und t/(m+t) im Bereich von 0,5 bis 1 liegt, wobei das durchschnittliche Molekulargewicht (Mn) (Zahlenmittel) des Halbäthers 500 bis 3000 beträgt, und eines eine C20-C150-Alkyl- oder -Alkenylgruppe enthaltenden Polyamins enthält.

in welcher EO Ethylenoxy ist, PO Propylenoxy ist, R2 C1-C20-Al- kyl bedeutet und m und t durchschnittliche Zahlen von Ethylenoxy- und Propylenoxygruppen in jedem Halbäthermolekül bedeuten derart, daß m/(m+t) im Bereich von 0 bis 0,5 liegt und t/(m+t) im Bereich von 0,5 bis 1 liegt, wobei das durchschnittliche Molekulargewicht (Mn) (Zahlenmittel) des Halbäthers 500 bis 3000 beträgt, und eines eine C20-C150-Alkyl- oder -Alkenylgruppe enthaltenden Polyamins enthält.

7. Eine Benzinzusammensetzung nach Anspruch 6, welche 100 bis 1200 Gewichtsteile p.M.

des Polyolefins und/oder Polyoxyalkylenglykol-Halbäthers und 5 bis 200 Gewichtsteile

p.M. des die Alkyl- oder Alkenylgruppe enthaltenden Polyamins enthält.

8. Ein Konzentrat, das sich zur Zugabe zu einem Benzin eignet, umfassend ein mit dem

Benzin kompatibles Verdünnungsmittel mit 20 bis 50 Gew.%, bezogen auf das Verdünnungsmittel,

eines Alkalimetallsalzes eines Teilesters eines Alkylpolyätherlakohols der allgemeinen

Formel

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoff- atom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoff- atom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

9. Eine Methode zum Betreiben eines Vergaser-Verbrennungsmotors, welches das Einführen

einer Benzinzusammensetzung nach einem der Ansprüche 1 bis 7 in den genannten Motor

umfaßt.

10. Verwendung eines Alkalimetallsalzes eines Teilesters eines Alkylpolyätheralkohols

der allgemeinen Formel

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem deralpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden sein kann, als Zündhilfsmittel und Mittel zum Verhindern des Hängenbleibens der Ventile in einer Benzinzusammensetzung, die einen größeren Teil eines für die Verwendung in Vergasermotoren geeigneten Benzins umfaßt.

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem deralpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden sein kann, als Zündhilfsmittel und Mittel zum Verhindern des Hängenbleibens der Ventile in einer Benzinzusammensetzung, die einen größeren Teil eines für die Verwendung in Vergasermotoren geeigneten Benzins umfaßt.

Patentansprüche für folgende(n) Vertragsstaat(en) : ES

1. Ein Verfahren zur Herstellung einer Benzinzusammensetzung, welches das Vermischen

eines größeren Teils eines für den Einsatz in Vergasermotoren geeigneten Benzins und

eines kleineren Teils eines Alkalimetallsalzes eines Teilesters eines Alkylpolyätheralkohols

der allgemeinen Formel (I)

in welcher n eine ganze Zahl von 4 bis 25 ist, R eine C6-C20-Alkylgruppe ist und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat umfaßt, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

in welcher n eine ganze Zahl von 4 bis 25 ist, R eine C6-C20-Alkylgruppe ist und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat umfaßt, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

2. Ein Verfahren nach Anspruch 1, in welchem das Alkalimetall Kalium ist.

3. Ein Verfahren nach Anspruch 1 oder 2, in welchem die aliphatische Kohlenwasserstoffgruppe

von einem Polyolefin abgeleitet ist, dessen Monomere 2 bis 6 Kohlenstoffatome aufweisen.

4. Ein Verfahren nach einem der vorstehenden Ansprüche, in welchem die aliphatische

Kohlenwasserstoffgruppe 15 bis 45 Kohlenstoffatome aufweist.

5. Ein Verfahren nach einem der vorstehenden Ansprüche, in welchem R eine Cg-C,5-Alkylgruppe ist.

6. Ein Verfahren nach einem der vorstehenden Ansprüche, welches zusätzlich das Vermischen

von geringen Mengen eines Polyolefins, das von einem C2-C6-Monomer abgeleitet ist, und/oder eines Polyoxyalkylenglykol-Hälbäthers der allgemeinen

Formel (II),

in welcher EO Ethylenoxy ist, PO Propylenoxy ist, R2 C1-C20-Alkyl bedeutet und m und t durchschnittliche Zahlen von Ethylenoxy- und Propylenoxygruppen in jedem Halbäthermolekül bedeuten derart, daß m/(m+t) im Bereich von 0 bis 0,5 liegt und t/(m+t) im Bereich von 0,5 bis 1 liegt, wobei das durchschnittliche Molekulargewicht (Mn) (Zahlenmittel) des Halbäthers 500 bis 3000 beträgt, und eines eine C20-C150-Alkyl- oder -Alkenylgruppe enthaltenden Polyamins umfaßt.

in welcher EO Ethylenoxy ist, PO Propylenoxy ist, R2 C1-C20-Alkyl bedeutet und m und t durchschnittliche Zahlen von Ethylenoxy- und Propylenoxygruppen in jedem Halbäthermolekül bedeuten derart, daß m/(m+t) im Bereich von 0 bis 0,5 liegt und t/(m+t) im Bereich von 0,5 bis 1 liegt, wobei das durchschnittliche Molekulargewicht (Mn) (Zahlenmittel) des Halbäthers 500 bis 3000 beträgt, und eines eine C20-C150-Alkyl- oder -Alkenylgruppe enthaltenden Polyamins umfaßt.

7. Ein Verfahren nach Anspruch 6, welches das Mischen von 100 bis 1200 Gewichtsteilen

p.M. des Polyolefins und/oder Polyoxyalkylenglykol-Halbäthers und von 5 bis 200 Gewichtsteilen

p.M. des die Alkyl-oder Alkenylgruppe enthaltenden Polyamins umfaßt.

8. Ein Verfahren zur Herstellung eines Konzentrats, das sich zurZugabe zu einem Benzin

eignet, umfassend das Vermischen eines mit dem Benzin kompatiblen Verdünnungsmittel

mit 20 bis 50 Gew.%, bezogen auf das Verdünnungsmittel, eines Alkalimetallsalzes eines

Tei lesters eines Alkylpolyätherlakohols der allgemeinen Formel

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoff- atom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoff- atom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem der alpha-Kohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist.

9. Eine Methode zum Betreiben eines Vergaser-Verbrennungsmotors, welche das Einführen

einer Benzinzusammensetzung nach einem der Ansprüche 1 bis 7 in den genannten Motor

umfaßt.

10. Verwendung eines Alkalimetallsalzes eines Teilesters eines Alkylpolyätheralkohols

der allgemeinen Formel

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem der alphaKohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist, als Zündhilfsmittel und Mittel zum Verhindern des Hängenbleibens der Ventile in einer Benzinzusammensetzung, die einen größeren Teil eines für die Verwendung in Vergasermotoren geeigneten Benzins umfaßt.

in welcher n eine ganze Zahl von 4 bis 25 ist, Reine C6-C20-Alkylgruppe bedeutet und jedes R1 unabhängig ein Wasserstoffatom oder eine C1-C10-Alkylgruppe ist, mit einem Bernsteinsäurederivat, das als Substituenten an mindestens einem der alphaKohlenstoffatome eine unsubstituierte oder substituierte aliphatische Kohlenwasserstoffgruppe mit 15 bis 200 Kohlenstoffatomen aufweist, die gegebenenfalls mittels einer Kohlenwasserstoffgruppe mit 1 bis 6 Kohlenstoffatomen unter Bildung einer Ringstruktur an das andere alpha-Kohlenstoffatom gebunden ist, als Zündhilfsmittel und Mittel zum Verhindern des Hängenbleibens der Ventile in einer Benzinzusammensetzung, die einen größeren Teil eines für die Verwendung in Vergasermotoren geeigneten Benzins umfaßt.

Revendications pour l'(les) Etat(s) contractant(s) suivant(s) : suivants : BE, DE,

FR, GB, IT, NL

1. Une composition d'essence comprenant une quantité majeure d'une essence utilisable

dans des moteurs à allumage par étincelle et une quantité mineure d'un sel de métal

alcalin d'un ester:partiel d'un alcoyl polyéther alcool de la formule générale

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui éventuellement est relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui éventuellement est relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

2. Une composition d'essence selon la revendication 1, dans laquelle le métal alcalin

est du potassium.

3. Une composition d'essence selon la revendication 1 ou la revendication 2, dans

laquelle le groupe d'hydrocarbure aliphatique est dérivé d'une polyoléfine, dont les

monomères ont 2 à 6 atomes de carbone.

4. Une composition d'essence selon l'une quelconque des revendications précédentes,

dans laquelle le groupe d'hydrocarbure aliphatique a de 15 à 45 atomes de carbone.

5. Une composition d'essence selon l'une quelconque des revendications précédentes,

dans laquelle R représente un groupe alcoyle en C9-C15.

6. Une composition d'essence selon l'une quelconque des revendications précédentes,

qui comprend en outre des quantités mineures d'une polyoléfine dérivée d'un monomère

en C2-C6 et/ou d'un hémi-éther de polyoxyalcoylène glycol de la formule générale

dans laquelle EO représente une portion éthylèneoxy, PO représente une portion propylèneoxy, R2 est un groupe alcoyle en C1-C20 et m et t représentent des nombres moyens de portions éthylèneoxy et propylèneoxy dans chaque molécule d'hémi-éther tels que le rapport m/(m+t) soit compris entre 0 et 0,5 et le rapport t/(m+t) entre 0,5 et 1, le poids moléculaire moyen en nombre (Mn) de l'hémi-éther étant compris entre 500 et 3000, et d'une polyamine contenant un groupe alcoyle ou alcényle en C20-C150.

dans laquelle EO représente une portion éthylèneoxy, PO représente une portion propylèneoxy, R2 est un groupe alcoyle en C1-C20 et m et t représentent des nombres moyens de portions éthylèneoxy et propylèneoxy dans chaque molécule d'hémi-éther tels que le rapport m/(m+t) soit compris entre 0 et 0,5 et le rapport t/(m+t) entre 0,5 et 1, le poids moléculaire moyen en nombre (Mn) de l'hémi-éther étant compris entre 500 et 3000, et d'une polyamine contenant un groupe alcoyle ou alcényle en C20-C150.

7. Une composition d'essence selon la revendication 6, qui contient de 100 à 1200

ppm en poids de la polyoléfine et/ou de l'hémi-éther de polyoxyalcoylène glycol et

de 5 à 200 ppm en poids de la polyamine contenant un groupe alcoyle ou alcényle.

8. Un concentré convenable pour addition à l'essence comprenant un diluant compatible

avec l'essence avec 20 à 50 % en poids, par rapport au diluant, d'un sel de métal

alcalin d'un ester partiel d'un alcoyl polyéther alcool de la formule générale

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

9. Une méthode pour faire fonctionner un moteur à combustion interne à allumage par

étincelle, qui comprend l'introduction dans le moteur d'une composition d'essence

selon l'une quelconque des revendications 1 à 7.

10. L'utilisation d'un sel de métal alcalin d'un ester partiel d'un alcoyl polyéther

alcool de la formule générale

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique, en tant qu'adjuvant d'allumage ou agent contre le collage des soupapes dans une composition d'essence comprenant une portion majeure d'une essence utilisable dans des moteurs à allumage par étincelle.

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique, en tant qu'adjuvant d'allumage ou agent contre le collage des soupapes dans une composition d'essence comprenant une portion majeure d'une essence utilisable dans des moteurs à allumage par étincelle.

Revendications pour l'(les) Etat(s) contractant(s) suivant(s) : suivant : ES

1. Un procédé pour la préparation d'une composition d'essence, qui comprend l'opération

de mélange d'une quantité majeure d'une essence utilisable dans des moteurs à allumage

par étincelle et d'une quantité mineure d'un sel de métal alcalin d'un ester partiel

d'un alcoyl polyester alcool de la formule générale

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

2. Un procédé selon la revendication 1, dans lequel le métal alcalin est du potassium.

3. Un procédé selon la revendication 1 ou la revendication 2, dans lequel le groupe

d'hydrocarbure aliphatique est dérivé d'une polyoléfine, dont les monomères ont 2

à 6 atomes de carbone.

4. Un procédé selon l'une quelconque des revendications précédentes, dans lequel le

groupe d'hydrocarbure aliphatique a de 15 à 45 atomes de carbone.

5. Un procédé selon l'une quelconque des revendications précédentes, dans lequel R

représente un groupe alcoyle en C9-C15·

6. Un procédé selon l'une quelconque des revendications précédentes, dans lequel en

outre on mélange des quantités mineures d'une polyoléfine dérivée d'un monomère en

C2-C6 et/ou d'un hémi-éther de polyoxyalcoylène glycol de la formule générale

dans laquelle EO représente une portion éthylèneoxy, PO représente une portion propylèneoxy, R2 est un groupe alcoyle en C1-C20 et m et t représentent des nombres moyens de portions éthylèneoxy et propylèneoxy dans chaque molécule d'hémi-éther tels que le rapport m/(m+t) soit compris entre 0 et 0,5 et le rapport t/(m+t) entre 0,5 et 1, le poids moléculaire moyen en nombre de l'hémi-éther étant compris entre 500 et 3000, et d'une polyamine contenant un groupe alcoyle ou alcényle en C20-C150.

dans laquelle EO représente une portion éthylèneoxy, PO représente une portion propylèneoxy, R2 est un groupe alcoyle en C1-C20 et m et t représentent des nombres moyens de portions éthylèneoxy et propylèneoxy dans chaque molécule d'hémi-éther tels que le rapport m/(m+t) soit compris entre 0 et 0,5 et le rapport t/(m+t) entre 0,5 et 1, le poids moléculaire moyen en nombre de l'hémi-éther étant compris entre 500 et 3000, et d'une polyamine contenant un groupe alcoyle ou alcényle en C20-C150.

7. Un procédé selon la revendication 6, qui comprend l'opération de mélange de 100

à 1200 ppm en poids de la polyoléfine et/ou de l'hémi-éther de polyoxyalcoylène glycol

et de 5 à 200 ppm en poids de la polyamine contenant le groupe alcoyle ou alcényle.

8. Un procédé de préparation d'un concentré convenable pour addition à l'essence,

qui comprend l'opération consistant à mélanger un diluant compatible avec l'essence

avec 20 à 50 % en poids, par rapport au diluant, d'un sel de métal alcalin d'un ester

partiel d'un alcoyl polyéther alcool de la formule générale

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement rélié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement rélié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique.

9. Une méthode pour faire fonctionner un moteur à combustion interne à allumage par

étincelle, qui comprend l'introduction dans le moteur d'une composition d'essence

préparée par un procédé selon l'une quelconque des revendications 1 à 7.

10. L'utilisation d'un sel de métal alcalin d'un ester partiel d'un alcoyl polyéther

alcool de la formule générale

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique,en tant qu'adjuvant d'allumage et agent contre le collage des soupapes dans une composition d'essence comprenant une portion majeure d'une essence utilisable dans des moteurs à allumage par étincelle.

dans laquelle n est un nombre entier de 4 à 25, R représente un groupe alcoyle en C6-C20 et chaque R1 indépendamment représente un atome d'hydrogène ou un groupe alcoyle en C1-C10, avec un dérivé d'acide succinique ayant comme substituant sur au moins un de ses atomes de carbone alpha un groupe d'hydrocarbure aliphatique non-substitué ou substitué ayant de 15 à 200 atomes de carbone qui est éventuellement relié à l'autre atome de carbone alpha au moyen d'une portion hydrocarbure ayant de 1 à 6 atomes de carbone, formant une structure cyclique,en tant qu'adjuvant d'allumage et agent contre le collage des soupapes dans une composition d'essence comprenant une portion majeure d'une essence utilisable dans des moteurs à allumage par étincelle.