| (19) |

|

|

(11) |

EP 0 515 698 B1 |

| (12) |

EUROPEAN PATENT SPECIFICATION |

| (45) |

Mention of the grant of the patent: |

|

29.07.1998 Bulletin 1998/31 |

| (22) |

Date of filing: 06.12.1991 |

|

| (86) |

International application number: |

|

PCT/JP9101/696 |

| (87) |

International publication number: |

|

WO 9210/579 (25.06.1992 Gazette 1992/14) |

|

| (54) |

Process for producing D-alpha-amino acids

Verfahren zur Herstellung von D-Alpha-Aminosäuren

Procédé de production de D-alpha aminoacides

|

| (84) |

Designated Contracting States: |

|

BE DE ES FR GB IT NL |

| (30) |

Priority: |

07.12.1990 JP 400848/90

27.12.1990 JP 407922/90

11.04.1991 JP 78840/91

|

| (43) |

Date of publication of application: |

|

02.12.1992 Bulletin 1992/49 |

| (73) |

Proprietor: KANEGAFUCHI KAGAKU KOGYO KABUSHIKI KAISHA |

|

Kita-ku

Osaka-shi

Osaka-fu 530 (JP) |

|

| (72) |

Inventors: |

|

- NANBA, Hironori

Takasago-shi,

Hyogo 676 (JP)

- YAMADA, Yukio

Kakogawa-shi,

Hyogo 675 (JP)

- TAKANO, Masayuki,

106, Leopalace

Futami-cho,

Akashi-shiHyogo 674 (JP)

- IKENAKA, Yasuhiro

Akasi-shi,

Hyogo 673 (JP)

- TAKAHASHI, Satomi

Kobe-shi,

Hyogo 655 (JP)

- YAJIMA, Kazuyoshi

Suma-ku,

Kobe-shi,

Hyogo 654-01 (JP)

|

| (74) |

Representative: Kolb, Helga, Dr. Dipl.-Chem. et al |

|

Hoffmann Eitle,

Patent- und Rechtsanwälte,

Postfach 81 04 20

81904 München

81904 München (DE) |

| (56) |

References cited: :

EP-A- 0 136 359

GB-A- 1 534 426

JP-A-63 024 894

JP-B-57 018 793

|

EP-A- 0 261 836

GB-A- 2 022 581

JP-A-63 185 382

|

|

| |

|

|

- PATENT ABSTRACTS OF JAPAN vol. 12, no. 230 (C-508)(3077) 29 June 1988 & JP-A-63 024

894 (AJINOMOTO CO INC) 2 February 1988

- BIOTECHNOLOGY AND BIOENGINEERING. vol. 23, no. 10 , 1981 , NEW YORK US pages 2173

- 2183 R. OLIVIERI ET AL 'Microbial transformation of racemic hydantoins to d-amino

acids'

|

|

| |

|

| Note: Within nine months from the publication of the mention of the grant of the European

patent, any person may give notice to the European Patent Office of opposition to

the European patent

granted. Notice of opposition shall be filed in a written reasoned statement. It shall

not be deemed to

have been filed until the opposition fee has been paid. (Art. 99(1) European Patent

Convention).

|

Technical field

[0001] The present invention relates to a process for the production of D-α-amino acids,

and more particularly, to a process for the production of D-α-amino acids using a

novel transformant having a gene which is related to an enzyme capable of converting

D-N-carbamoyl-α-amino acids into the corresponding D-α-amino acids.

Background art

[0002] Optically-active D-α-amino acids are important compounds as intermediates of drugs,

and particularly, D-phenylglycine, D-parahydroxyphenyl-glycine and other intermediates

for the production of semisynthesized penicillin or cephalosporin antibiotics are

industrially useful compounds. As a process for the production of such D-α-amino acids,

there is a well-known process in which carbamoyl groups of the corresponding D-N-carbamoyl-α-amino

acids are removed to give the desired D-α-amino acids. The removal of carbamoyl groups

in this process is achieved by a chemical process (e.g., the specification of Japanese

Patent Publication No. 58-4707) or by a process utilizing the enzymatic reaction of

microorganisms (e.g., the specifications of Japanese Patent Publication Nos. 57-18793,

63-20520, and 1-48758).

Problems to be solved by the invention

[0003] In a chemical process employed for the removal of carbamoyl groups as described above,

a great amount of mineral acid such as sulfuric acid is used, and therefore, there

will occur serious environmental problems regarding to the disposal thereof and the

like. On the other hand, a process utilizing the enzymatic reaction of microorganisms

has several drawbacks that microorganisms hitherto known as a source of enzyme supply

cannot produce a sufficient amount of enzymes and that expensive hydantoin or N-carbamoylamino

acid compounds are required for the production of enzymes.

Means for solving the problems

[0004] For the purpose of solving such problems, the objects of the present invention are

to prepare microorganisms having high productivity of enzymes, as well as to produce

D-α-amino acids with high efficiency by use of a source of enzyme supply thus obtained.

[0005] A similar technique is disclosed in Japanese Patent Laid-open Publication No. 63-24894.

However, this technique relates to the production of L-α-amino acids, and there is

no experimental example describing the production of D-α-amino acids.

[0006] The present invention provides a process for the production of D-α-amino acids, by

a method in that D-N-carbamoyl-α-amino acids are converted into the corresponding

D-α-amino acids in an aqueous medium with the aid of an action of an enzyme capable

of converting D-N-carbamoyl-α-amino acids by removal of their carbamoyl groups into

the corresponding D-α-amino acids, characterized in that said enzyme is produced by

a transformant which is obtainable by transformation of host bacterial cells selected

from the microorganisms belonging to the genera

Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium, and

Brevibacterium, with a recombinant DNA comprising a vector DNA and a DNA fragment containing a gene

encoding said enzyme after which the D-α-amino acids produced are collected.

[0007] By the way, no example has hitherto been known that a recombinant DNA comprising

a vector and a gene which is related to an enzyme capable of converting D-N-carbamoyl-α-amino

acids by removal of their carbamoyl groups into the corresponding D-α-amino acids

is incorporated into microorganisms to achieve the expression of the gene. Such a

technique was not succeeded until the present invention has been completed.

[0008] The enzymes capable of converting D-N-carbamoyl-α-amino acids by removal of their

carbamoyl groups into the corresponding D-α-amino acids are, in fact, not limited

to those which specifically act on the D-isomers or those which act on either D- or

L-isomers. In particular, enzymes having a strict stereoselectivity to D-N-carbamoyl-α-amino

acids may be referred to as D-N-carbamoyl-α-amino acid amidohydrolases

[0009] Examples of the DNA fragment containing a gene which can be used in the present invention

are those which are derived from eucaryotes, prokaryotes, viruses, bacteriophages

or plasmids, and which contain a gene related to a particular D-N-carbamoyl-α-amino

acid amidohydrolase. As the gene derived from prokaryotes, preferred are those which

are derived from bacteria belonging to the genus, for example,

Pseudomonas, Agrobacterium, Aerobacter, Aeromonas, Brevibacterium, Bacillus, Flavobacterium, Serratia, Micrococcus, Arthrobacter, Alkaligenes, Achromobacter, Moraxella, or

Paracoccus, and which are related to D-N-carbamoyl-α-amino-acid amidohydrolases. Specific examples

of such strains are as follows:

Aerobacter cloacae IAM 1221,

Bacillus macroides ATCC 12905,

Bacillus alvei IFO 3343,

Brevibacterium ammoniagenes IFO 12071,

Flavobacterium flavescens IFO 3086,

Sarcina lutea IFO 1099,

Serratia marcescens IFO 305

4,

Micrococcus luteus IFO 12708,

Aeromonas hydrophilia IFO 3820,

Agrobacterium species KNK 712 (FERM BP-1900),

Pseudomonas-sp. KNK 003A (FERM BP-3181),

Pseudomonas sp. KNK 505 (FERM BP-3182),

Agrobacterium 1302 NRRL B11291,

Alkaligenes aquamarinus AJ 11199,

Achromobacter liquefaciens AJ 11198,

Moraxella nonliquefaciens AJ 11221,

Paracoccus denitrificans AJ 11222,

Arthrobacter fragilus AJ 11223, and the like.

[0010] As the typical examples of the above bacteria, the microbiological characteristics

of

Agrobacterium species KNK 712 (FERM BP-1900),

Pseudomonas sp. KNK 003A (FERM BP-3181), and

Pseudomonas sp. KNK 505 (FERM BP-3182) are described below.

Agrobacterium species KNK 712 (FERM BP-1900)

[0011]

(a) Morphology

(1) Cell size and shape: 0.5-1.0 x 2.0-4.0 µm, rods

(2) Cellular polymorphism: none

(3) Motility and flagellar arrangement: active, subpolar

(4) Sporulation: none

(5) Gram-staining: negative

(b) Cultural characteristics on various media

(1) Meat extract agar plate culture:

satisfactory growth, round, ridgy, smooth margin, smooth wet surface, white to

cream-colored, glossy, opaque, liquid form

(2) Meat extract agar slant culture:

excellent growth, even growth on the inoculation line,- thick ridge, smooth wet

surface, smooth margin, white to cream-colored, glossy, opaque, no change in the medium

(3) Meat extract gelatin stab culture:

feeble growth, growth along the stab line, growth around the stab line, no gelatin

liquefaction, white to cream-colored, no change in transparency, no change in the

medium

(4) Meat extract liquid culture:

medium growth, uneven turbidity, flock formation, no surface growth

(5) Litmus milk: weak acid

(c) Physiological Characteristics

(1) Nitrate reduction: +

(2) Denitrification: +

(3) MR test: +

(4) Vp test: -

(5) Indole formation: -

(6) Hydrogen sulfide formation: -

(7) Starch hydrolysis: -

(8) Citrate utilization: - (Simmons medium)

(9) Inorganic nitrogen source: + (nitrates, ammonium salts)

(10) Urease: -

(11) Oxidase: +

(12) Catalase: +

(13) Growth range: 20-37°C, pH 6.5-8.5

(14) Attitude toward oxygen: aerobic

(15) O-F test: O type

(16) Formation of acid and gas from saccharide: Acid formation, -; Gas formation,

- (D-glucose)

(17) Malonate utilization: -

(18) Deaminase reaction of phenylalanine: -

(19) Decarboxylase reaction: - (lysine)

(20) Arginine dihydrolase reaction: -

(21) Casein degradation: -

(22) DNA degradation: -

(23) Auxotrophy: none

(24) Utilization of carbon compounds:

D-Glucose: +

L-Arabinose: +

Saccharose: +

D-Fructose: +

Malonate: -

Cellobiose: +

Ethanol: -

D-Xylose: +

D-Tartrate: -

Sorbitol: +

Citrate: -

Lactose: +

D-Mannitol: +

Meso-inositol: +

Raffinose: +

L-Rhamnose: +

Maltose: +

α-Methyl-D-glucoside: +

D-Mannose: +

Salicin: -

N-Acetylglucosamine: +

Gluconate: -

Caprate: -

Adipate: -

Phenylacetate: -

Methanol: -

(25) Egg york reaction:-

(26) β-Galactosidase: +

(27) Esculin hydrolysis: +

(28) Cytochrome oxidase: +

(29) Tween® degradation: - (Tween® 80)

(30) 3-Ketolactose formation: -

Pseudomonas sp. KNK 003A (FERM BP-3181)

[0012]

(a) Morphology:

(1) Cell size and shape: 0.5-0.7 × 1.2-2.5 µm, rods

(2) Cellular polymorphism: none

(3) Motility: active

(4) Sporulation: none

(5) Gram-staining: negative

(6) Colony shape: round, regular, entire, flat, smooth, shiny, semi-translucent, buff

(b) Physiological Characteristics

(1) Lysis by 3% KOH: +

(2) Aminopeptidase: +

(3) Oxidase: +

(4) Catalase: +

(5) Cell growth

Anaerobic condition: -

37/40°C: +/+

pH 5.6: -

Mac-Conkey agar: -

SS agar: -

Cetrimid agar: -

(6) Acid formation (O-F test)

Glucose aerobic condition: -

Glucose anaerobic condition: -

(7) Gas formation from glucose: -

(8) Acid formation (ASS)

Glucose: +

Fructose: -

Xylose: +

(9) ONPG: -

(10) ADH: -

(11) ODC: -

(12) VP: -

(13) Indole formation: -

(14) Nitrate reduction: -

(15) Denitrification: -

(16) Phenylalanine deaminase: -

(17) Levan formation from sucrose: -

(18) Lecithinase: -

(19) Urease: -

(20) Hydrolysis

Starch: -

Geratin: -

Casein: -

DNA: -

Tween® 80: -

Esculin: -

(21) Tyrosine degradation: -

(22) Utilization of various compounds

Acetate: weak

Adipate: -

Caprate: -

Citrate: -

Citraconate: -

Glycolate: -

Lactate: +

Levulinate: -

Malate: -

Malonate: -

Mesaconate: -

Phenylacetate: -

Suberate: -

m-Tartrate: -

D-Tartrate: -

L-Arabinose: +

Fructose: +

Glucose: +

Mannose: +

Maltose: -

Xylose: +

Saccharose: -

Trehalose: -

Ribose: -

Saccharate: -

Hydroxybutylate: -

Benzoate: -

Mannitol: +

Gluconate: +

2-Ketogluconate: +

N-Acethylglucosamine: -

L-Serine: -

L-Histidine: -

L-Valine: -

(23) Main respiratory quinone type: ubiquinone 10

Pseudomonas sp. KNK 505 (FERM BP-3182)

[0013]

(a) Morphology:

(1) Cell size and shape: 0.5-0.7 × 1.2-2.5 µm, rods

(2) Cellular polymorphism: none

(3) Motility: active

(4) Sporulation: none

(5) Gram-staining: negative

(6) Colony shape: round, regular, entire, flat, smooth, shiny, semi-translucent, buff

(b) Physiological Characteristics

(1) Lysis by 3% KOH: +

(2) Aminopeptidase: +

(3) Oxidase: +

(4) Catalase: +

(5) Cell growth

Anaerobic condition: -

37/40°C: +/+

pH 5.6: -

Mac-Conkey agar: -

SS agar: -

Cetrimid agar: -

(6) Acid formation (O-F test)

Glucose aerobic condition: -

Glucose anaerobic condition: -

(7) Gas formation from glucose: -

(8) Acid formation (ASS)

Glucose: +

Fructose: -

Xylose: +

(9) ONPG: -

(10) ADH: -

(11) ODC: -

(12) VP: -

(13) Indole formation: -

(14) Nitrate reduction: -

(15) Denitrification: -

(16) Phenylalanine deaminase: -

(17) Levan formation from sucrose: -

(18) Lecithinase: -

(19) Urease: -

(20) Hydrolysis

Starch: -

Geratin: -

Casein: -

DNA: -

Tween® 80: -

Esculin: -

(21) Tyrosine degradation: -

(22) Utilization of various compounds

Acetate: weak

Adipate: -

Caprate: -

Citrate: -

Citraconate: -

Glycolate: -

Lactate: +

Levulinate: -

Malate: -

Malonate: -

Mesaconate: -

Phenylacetate: -

Suberate: -

m-Tartrate: -

D-Tartrate: -

L-Arabinose: +

Fructose: +

Glucose: +

Mannose: +

Maltose: -

Xylose: +

Saccharose: -

Trehalose: -

Ribose: -

Saccharate: -

Hydroxybutylate: -

Benzoate: -

Mannitol: +

Gluconate: +

2-Ketogluconate: +

N-Acethylglucosamine: -

L-Serine: -

L-Histidine: -

L-Valine: -

(23) Main respiratory quinone type: ubiquinone 10

[0014] To obtain a gene from these strains, which is related to an enzyme capable of converting

D-N-carbamoyl-α-amino acids by removal of their carbamoyl groups into the corresponding

D-α-amino acids, usually, genetic DNA is extracted from the chromosome of microorganisms

according to the conventional procedure, after which a DNA fragment containing the

desired gene is obtained and subjected to an analysis for its base sequence. Moreover,

microorganisms which produce an enzyme capable of converting D-N-carbamoyl-α-amino

acids by removal of their carbamoyl groups into the corresponding D-α-amino acids,

as well as transformed microorganisms into which this enzyme gene has been incorporated,

are cultivated, and the produced enzyme is purified, after which the molecular weight

of its protein is determined and the amino acid sequence in the vicinity of its amino

terminus is determined by a gas-phase protein sequencer or the like. Then, this DNA

base sequence is compared with the amino terminal sequence of the protein, so that

the initiation site for genetic translation into a protein, of the base sequence portion

encoding an enzyme protein which is related to removal of carbamoyl groups is determined,

and taking into consideration the relation to the molecular weight of the protein,

it is confirmed that the enzyme protein is encoded in the gene portion extending from

this site to the termination codon, thereby verifying the desired gene (Molecular

Cloning, A Laboratory Manual, 2nd Ed., Cold Spring Harbor Laboratory Press, Chaps.

4 and 13). According to these procedures, DNA fragments of SEQ ID Nos. 1 and 2 in

the accompanying Sequence Listing were obtained from the strains

Agrobacterium species KNK 712 and

Pseudomonas sp. KNK 003A. The thus-obtained gene encoding the above enzyme-and/or DNA fragment

containing this gene are equivalent to DNA fragments having another base sequence

which encodes an amino acid sequence corresponding to the above gene and/or DNA fragment

because one amino acid usually corresponds to a plurality of base codons, and this

fact is obvious.

[0015] As the vector used in the present invention, plasmids, phages, or derivatives thereof

can be used, which are derived from microorganisms and can be autonomously grown in

cells of a bacteria belonging to the genus

Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Croynebacterium, or

Brevibacterium. For example, host-vector systems described in "Guidelines on Recombinant DNA Experiments"

(Ed., the Life Science Section of the Research Development Office-in the Science and

Technology Agency: revised on September 16, 1987), page 55, can be used. Moreover,

vectors, which have been modified to have a strong structural promoter for the purpose

of increasing the amount of enzyme to be produced, can also be used.

[0016] The preparation of a recombinant comprising a vector DNA and a gene-containing DNA

fragment can be conducted by freely using the known

in vitro recombinant DNA technique. The

in vitro DNA recombination is usually conducted by cleavage and ligation (ligase reaction)

of a vector DNA and a donor DNA containing the desired gene (e.g., see the specifications

of Japanese Patent Application No. 56-211908 and United States Patent No. 4,237,224).

Many kinds of recombinant DNA, in addition to the desired recombinant DNA, are produced

by ligase reaction, and therefore, for the purpose of selectively obtaining the desired

recombinant DNA, microorganisms belonging to the genus

Escherichia,

Pseudomonas,

Flavobacterium,

Bacillus,

Serratia,

Croynebacterium, or

Brevibacterium may be directly transformed with a ligase reaction mixture, and the resulting transformants

on which the inherited character from the genetic information of the desired gene

has been conferred may be selectively separated, and the desired recombinant DNA may

be extracted and isolated from their cultured bacterial cells.

[0017] For example, the recombinant can also be obtained without direct transformation of

bacterial species belonging to any one of the above genera; that is, the desired gene

is once cloned in a host vector system using other microorganisms, such as

Escherichia coli, after which recombinant DNA with an appropriate vector is

in vitro produced, and then the above bacterial species are transformed, followed by selective

separation of transformants in the same manner as described above.

[0018] The description of the following documents can be widely applied to the production

of recombinants: the specification of United States Patent No. 4,237,224 to S.N. Cohen,

et al.; "Idenshi-sousa Jikken-hou (Experimental Method of Gene Manipulation)" [Ed.,

Yasuyuki Takagi, Kohdansha Scientific (1980)]; Method in Enzymdogy,

68, Recombinant DNA [Ed., Ray Mv, Academic Press (1979)]; the specification of Japanese

Patent Application No. 56-211908, etc.

[0019] In the case of

Escherichia coli transformed with various kinds of recombinant DNA, a method for selecting, from the

transformed strains, particular transformed strains which have the desired gene, i.e.,

the gene of a particular D-N-carbamoyl-α-amino acid amidohydrolase, and in which that

gene has been expressed, is conducted as follows: colonies of the transformed strains

are first grown on the plate containing a selection marker, such as ampicillin. Then,

various colonies of these transformed strains having the recombinant DNA are collected

and suspended in physiological saline, after which this suspension is inoculated on

the minimum liquid medium containing a particular D-N-carbamoyl-α-amino acid as a

sole nitrogen source. On this medium, only transformed strains capable of utilizing

the D-N-carbamoyl-α-amino acid, i.e., transformed strains on which D-N-carbamoyl-α-amino

acid amidohydrolase activity has been now conferred, can be grown. The culture solution

thus obtained is inoculated on the above minimum medium, and such an operation is

repeated, resulting in an enrichment of the desired transformed strains. From this

enriched culture solution, bacterial cells are separated according to the conventional

method, and the separated transformed strains are cultivated to make a bacterial reaction

with a D-N-carbamoyl-α-amino acid as a substrate, whereby the transformed strains

containing the desired gene can be obtained by confirming the production of a D-α-amino

acid.

[0020] From the transformed strains thus obtained, recombinant DNA is extracted according

to the conventional method, such as a method using alkali denaturation (see Molecular

Cloning A Laboratory Manual, 2nd Ed., Cold Spring Harbor Laboratory Press, Chap. 1);

the structural gene of the desired enzyme in the DNA fragments containing the cloned

desired gene is subcloned and unnecessary DNA is removed; recombinant DNA modified

to have a strong promoter is prepared in a vector; the above host bacteria are transformed

therewith; and the resulting transformed strains are used to increase the amount of

the desired enzyme to be produced.

[0021] The introduced character of the recombinant DNA can be expressed by cultivating the

transformed strains on a conventional nutrient medium. In cases where the character

from the gene DNA or vector DNA is conferred on the recombinant DNA, any drug may

be supplemented to the medium depending upon that character.

[0022] To take the transformed strains thus obtained, as a source of enzyme supply, culture

may be prepared with the use of a conventional medium, and when necessary, it is also

possible to conduct a treatment for enzyme induction, such as an addition of hydantoin

compounds, D-N-carbamoyl-α-amino acids, isopropyl-1-thio-β-D-galactosides (IPTG),

or the like, and a temperature increase.

[0023] Usually, the medium used for cultivating the transformed strains may be a conventional

medium containing carbon sources, nitrogen sources, and inorganic ions. If organic

tracenutrients, such as vitamines and amino acids, are added thereto, satisfactory

results may be obtained in many cases. As the carbon sources, carbohydrates, such

as glucose and sucrose; organic acids, such as acetic acid; alcohols, and the like,

are conveniently used. As the nitrogen sources, ammonia gas, ammonia water, ammonium

salts, and the like, are used. As the inorganic ions, phosphate ion, magnesium ion,

potassium ion, iron ion, and the like, may be used.

[0024] If culture is prepared under aerobic conditions for 1-10 days, while adjusting the

pH and temperature to an appropriate range of 4-8 and 25-45°C, respectively, it is

possible to obtain desirable results.

[0025] Examples of the embodiments acting as an enzyme produced by the transformed strains

include culture solutions of the transformed strains, bacterial cells, treated bacterial

cells, enzymes extracted from bacterial cells, immobilized bacterial cells, and the

like.

[0026] As the bacterial cells, any of the culture solution as it is after completion of

cultivation, bacterial cells separated from the culture solution, washed bacterial

cells, and the like, can be used. As the treated bacterial cells, lyophilized bacterial

cells, acetone-dried bacterial cells, bacterial cells brought into contact with toluene

or detergents, lysozyme-treated bacterial cells, bacterial cells exposed to ultrasonic

waves, mechanically ground bacterial cells, and the like, can be used, as well as

enzyme extracts having the enzyme activity to convert D-N-carbamoyl-α-amino acids

obtained from these treated bacterial cells, by removal of their carbamoyl groups

into the corresponding D-α-amino-acids; these immobilized bacterial cells; insolubilized

treated bacterial cells; enzyme proteins fixed on a support for immobilization (e.g.,

anion exchange resin), and the like. For an immobilization method, for example, it

is possible to make reference to the specification of Japanese Patent Laid-open Publication

No. 63-185382.

[0027] As the support used for immobilization, suited are phenol-formaldehyde anion exchange

resins, such as Duolite A568 or DS17186 (Rohm & Haas Co.: registered trade mark);

and various anion exchange resins containing various amines, ammonium salts, or functional

groups of the diethanolamine type, for example, polystylene resins, such as Amberlite

IRA935, IRA945, IRA901 (Rohm & Haas Co.: registered trade mark), Lewatit OC1037 (Bayer

A.G.: registered trade mark), and Diaion EX-05 (Mitsubishi Chemical Industries Ltd.:

registered trade mark). Other supports, such as DEAE-cellulose, can also be used.

[0028] Further, to obtain stronger and more stable adsorption of enzymes, usually, cross-linking

agents are used, the preferred examples thereof being glutaraldehyde. As the enzyme

to be used, not only purified enzymes, but also those with different degrees of purification,

such as partially purified enzymes, suspensions of disintegrated bacterial cells,

and cell-free extracts, can be used.

[0029] The preparation of immobilized enzymes can be conducted by using an enzyme solution

and the conventional method in which, for example, enzymes are adsorbed on a support,

followed by cross-linking treatment.

[0030] D-N-carbamoyl-α-amino acids, which are used as a substrate of the enzymatic reaction

of the present invention, can be represented by the formula: R-CH(NHCONH

2)-COOH, and as a practical embodiment, in cases where the enzyme used has strict stereoselectivity

to D-N-carbamoyl-α-amino acids, it can be used as the D-form or a mixture of the D-

and L-forms. Moreover, in cases where the stereo-selectivity is not strict because

enzymes also act on L-carbamoyl amino acids, or where enzymes are used as an enzyme

mixture also acting on the L-form thereof, it is preferred that only enzymes of the

D-form are used to produce α-amino acids of the D-form.

[0031] The substituent R can be selected in a wide range, as described in the specifications

of Japanese Patent Publication Nos. 57-18793, 63-20520, and 1-48758; in particular,

to provide industrially useful compounds, such as intermediates of drugs, it is preferred

that R is phenyl, phenyl substituted with hydroxy, alkyl, substituted alkyl, aralkyl,

or thienyl. In the case of phenyl substituted with hydroxy, the number of hydroxy

is one or more, and they may be attached at any of o-, m-, and p-positions, with the

typical example thereof being p-hydroxyphenyl. The alkyl group is such a group of

1-4 carbon atoms that the corresponding amino acid becomes D-alanine, D-valine, D-leucine,

D-isoleucine, or-the like. The substituted alkyl group is such an alkyl having 1-4

carbon atoms substituted with hydroxy, alkylthio, carboxyl, amino, phenyl, phenyl

substituted with hydroxy, amido, or the like, that the corresponding amino acid becomes

D-serine, D-threonine, D-methionine, D-cysteine, D-asparagine, D-glutamine, D-tyrosine,

D-tryptophane, D-aspartic acid, D-glutamic acid, D-histidine, D-lysine, D-arginine,

D-citrulline, or the like. The aralkyl group is such a group having 7-8 carbon atoms,

for example, benzyl or phenyl, that the corresponding amino acid becomes D-phenylalanine

or the like.

[0032] As the aqueous medium, those containing water, buffers, or organic solvents, such

as ethanol, can be used. Further, when necessary, nutrients required for the growth

of microorganisms, antioxidants, detergents, coenzymes, hydroxylamines, metals, or

the like, can also be added to the aqueous medium.

[0033] In cases where, while cultivating the bacterial cells of the above microorganisms

in a water-soluble medium, the bacterial cells are brought into contact with a particular

D-N-carbamoyl-α-amino acid, an aqueous medium containing not only a D-N-α-amino acid

but also nutrients required for the growth of microorganisms, such as carbon sources,

nitrogen sources, and inorganic ions, is used. Further, if organic tracenutrients,

such as vitamines and amino acids, are added thereto, satisfactory results can be

obtained in many cases. As the carbon sources, carbohydrates, such as glucose and

sucrose; organic acids, such as acetic acid; alcohols, and the like, are conveniently

used. As the nitrogen sources, ammonia gas, ammonia water, ammonium salts, and the

like, are used. As the inorganic ions, phosphate ion, magnesium ion, potassium ion,

iron ion, and the like, may be used.

[0034] The cultivation is conducted under aerobic conditions, while adjusting the pH and

temperature to an appropriate range of 4-8 and 25-45°C, respectively. If the cultivation

is conducted for 1-10 days, D-N-carbamoyl-α-amino acids can be converted into only

D-α-amino acids with high efficiency.

[0035] To the contrary, in cases where the culture solution of the above microorganisms

is allowed as it is, to react with cultivated bacterial cells, treated bacterial cells,

enzyme extracts, immobilized bacterial cells, insolubilized bacterial cells, or fixed

enzyme proteins, in an aqueous medium containing a particular D-N-carbamoyl-α-amino

acid dissolved or suspended, the reaction mixture may be allowed to stand for some

time or stirred, while maintaining at an appropriate temperature of 10-80°C and pH

of 4-9.5. Thus, if 5-100 hours have run their course, the corresponding D-α-amino

acid is produced in large quantities and enriched in the aqueous medium. Moreover,

the D-N-carbamoyl-α-amino acid may be added in separate portions with the progress

of reaction. The produced D-α-amino acid can be separated and purified by a conventional

separation method.

[0036] The D-α-amino acid thus obtained can be represented by the formula: R-CHNH

2COOH (R is as defined above).

Examples

[0037] The following will describe the embodiments of the present invention. The D-α-amino

acid produced was detected and determined by high performance liquid chromatography

(HPLC) or thin layer chromatography (TLC).

Example 1

[0038] Preparation of recombinant DNA comprising chromosome DNA from

Agrobacterium species KNK 712 (FERM BP-1900) and vector DNA:-

[0039] Agrobacterium species KNK 712 (FERM BP-1900) was cultivated in 2 liters of L-broth (10 g of peptone/liter,

5 g of yeast extract/liter, 5 g of sodium chloride/liter; pH 7.0) at 33°C for 27 hours,

after which cultures were harvested to give 20 g of bacterial cells. From the bacterial

cells obtained, chromosome DNA was extracted according to the Marmur method. To 250

µg of this chromosome DNA, 2 U of

Sau3AI were added, and allowed to react at 37°C for 30 minutes, thereby causing partial

digestion. From the partially digested DNA, 4-9 kbp DNA fragments were obtained by

agarose gel electrophoresis. On the other hand, plasmid pUC_18 was completely digested

with

BamHI, and ligated with T4 DNA ligase to the above-obtained DNA fragments from chromosome,

resulting in a mixed solution of various recombinant plasmids.

Example 2

[0040] Selection of plasmid derived from

Agrobacterium species KNK 712 (FERM BP-1900) and containing gene related to conversion of D-N-carbamoyl-α-amino

acid into the corresponding D-α-amino acid:-

[0041] Using the mixed plasmid solution of Example 1,

Escherichia coli JM 109 was transformed according to the conventional method. This was inoculated

on the medium of Table 1, containing ampicillin as a selection marker.

Table 1

| Polypeptone |

1 g |

| Yeast extract |

0.5 g |

| Sodium chloride |

0.5 g |

| Ampicillin |

100 mg |

| Ager |

15 g |

| Water was added to the volume of 1 liter (pH 7.0). |

[0042] Water was added to the volume of 1 liter (pH 7.0).

[0043] The grown colonies were collected and inoculated into the liquid medium of Table

2, containing D-N-carbamoyl-alanine as a sole nitrogen source, followed by cultivation.

Table 2

| Na2HPO4 |

6 g |

| KH2PO4 |

3 g |

| NaCl |

0.5 g |

| MgSO4 |

0.12 g |

| CaCl2 |

11 mg |

| Glucose |

2 g |

| Ampicillin |

50 mg |

| Thiamin |

1 mg |

| D-N-Carbamoyl-alanine |

1 g |

| Water was added to the volume of 1 liter (pH 7.0). |

[0044] Water was added to the volume of 1 liter (pH 7.0).

[0045] Only the transformed strains expressing the desired gene can be grown on the medium

of Table 2 by utilizing D-N-carbamoyl-alanine as a nitrogen source. The culture solution

in the medium of Table 2 was inoculated into the same medium as used above, and this

operation was repeated for enrichment of the desired transformed strains. From the

enriched culture solution, the transformed strains were purely separated with the

medium of Table 1. These purely separated cells were inoculated into 10 ml of L-broth

(10 g of peptone/liter, 5 g of yeast extract/liter, 5 g of sodium chloride/liter;

pH 7.0) containing 100 mg/liter of ampicillin, and incubated at 37°C for 16 hours,

after which 1 ml of the culture solution was harvested and the supernatant was removed

therefrom, followed by suspension of the bacterial cells in 0.5 ml of substrate solution

(0.5% D-N-carbamoyl-parahydroxyphenylglycine, 0.05% Triton® X-100, 0.1 M phosphate

buffer (hereinafter referred to as KPB); pH 7.0) and allowing to react at 37°C for

3 hours. This reaction mixture was spotted on TLC and developed, followed by staining

with ninhydrin, resulting in a spot of D-parahydroxyphenylglycine which was in agreement

with the standard. From this fact, it was confirmed that the transformed strains purely

separated have a plasmid containing a gene related to the desired enzyme. The plasmid

contained in these strains was named pAHD 101.

[0046] Then, from the above transformed strains, pAHD 101 was prepared in large quantities

according to the alkali denaturation method, followed by mapping, which reveled that

it had the structure shown in Fig. 1.

[0047] Escherichia coli JM 109 transformed with pAHD 101 was named

Escherichia coli JM 109 pAHD 101.

Example 3

[0048] Selection of plasmid derived from

Pseudomonas sp. KNK 003A (FERM BP-3181) and containing gene related to conversion of D-N-carbamoyl-α-amino

acid into the corresponding D-α-amino acid:-

[0049] In the same manner as described in Example 1, a mixed solution of various recombinant

plasmids formed from chromosome DNA fragments of

Pseudomonas sp. KNK 003A (FERM BP-3181) and plasmid pUC18 was obtained. Using this mixed solution,

Escherichia coli JM 109 was transformed according to the conventional method. From these various transformed

strains, particular transformed strains having a plasmid which contains a gene related

to an enzyme capable of converting D-N-carbamoyl-α-amino acids into the corresponding

D-α-amino acids were obtained in the same manner as described in Example 2, except

that the liquid medium of Table 2, containing 100 mg/liter of IPTG, was used in place

of the liquid medium of Table 2. The plasmid contained in these strains was named

pPHD 301.

[0050] Then, from the above transformed strains, pPHD 301 was prepared in large quantities,

followed by mapping, which revealed that it had the structure shown in Fig. 2.

[0051] Escherichia coli JM 109 transformed with pPHD 301 was named

Escherichia coli JM 109 pPHD 301.

Example 4

Subcloning of pAHD 101

[0052] The pAHD 101 obtained in Example 2 was completely digested with

SmaI and

EcoRI, and a 2.7 kbp

SmaI-

EcoRI fragment was obtained by agarose gel electrophoresis. On the other hand, plasmid

pUC 19 was completely digested with

SmaI and

EcoRI, and ligated with T4 DNA ligase to the

SmaI-

EcoRI fragment of pAHD 101, after which

Escherichia coli JM 109 was transformed with this ligated plasmid and the transformed strains were

cultivated on an L-medium (1% peptone, 0.5% yeast extract, 0.5% sodium chloride, 1.5%

agar; pH 7.0) containing isopropyl-1-thio-β-D-galactoside (IPTG), 5-chloro-4-bromo-3-indolyl-β-D-galactose

(Xgal) and ampicillin.

[0053] The plasmid corresponding to pUC 19 containing the

SmaI-

EcoRI fragment of pAHD 101 formed white colonies without exhibiting blue color, and therefore,

these white colonies were selected. To confirm that these selected bacteria have the

desired enzyme activity, they were inoculated into 10 ml of L-broth (1% peptone, 0.5%

yeast extract, 0.5% sodium chloride) containing 100 mg/liter of ampicillin after cultivation

of which 1 ml of the culture solution was harvested and the supernatant was removed

therefrom, and the bacterial cells were suspended in 0.5 ml of substrate solution

(0.5% D-N-carbamoyl-parahydroxyphenylglycine, 0.05% Triton® X-100, 0.1 M phosphate

buffer; pH 7.0), followed by reaction at 37°C for 3 hours. This reaction mixture was

spotted on TLC and developed, followed by staining with ninhydrin, resulting in a

spot of D-parahydroxyphenylglycine which was in agreement with the standard. The plasmid

contained in these transformed strains was named pAD 107.

[0054] Then, the plasmid pAD 107 was prepared and partially hydrolyzed with

SalI, followed by agarose gel electrophoresis to give a 4.5 kbp fragment containing the

pUC 19 portion. This fragment was circularized with T4 DNA ligase, and this plasmid

was used to transform

Escherichia coli JM 109. The trasformed strains were obtained from the L-medium containing ampicillin

and bacterial reaction was conducted in the same manner as described above, thereby

obtaining transformed strains having the ability to convert D-N-carbamoyl-parahydroxyphenylglycine

into D-parahydroxyphenylglycine. The plasmid contained in these transformed strains

was named pAD 108. The pAD 108 was prepared form the above transformed strains, followed

by mapping, which revealed that it had the structure shown in Fig. 3.

[0055] Escherichia coli JM 109 transformed with pAD 108 was named

Escherichia coli JM 109 pAD 108. The accession number given from the Fermentation Research Institute

was FERM BP-3184.

Example 5

Subcloning of pPHD 301

[0056] The pPHD 301 obtained in Example 3 was completely digested with

AccI, and a 5.2 kbp fragment containing the pUC 18 portion was obtained by agarose gel

electrophoresis. This fragment was circularized with T4 DNA ligase, and this plasmid

was used to transform

Escherichia coli JM 109. The transformed strains were obtained from an L-medium containing ampicillin

and bacterial reaction was conducted in the same manner as described in Example 4,

thereby obtaining transformed strains having the ability to convert D-N-carbamoyl-parahydroxyphenylglycine

into D-parahydroxy-phenylglycine. The plasmid contained in these transformed strains

was named pPD 302.

[0057] Then, the plasmid pPD 302 was prepared and completely digested with

SphI and

AccI, after which a 1.8 kbp

SphI-

AccI fragment was obtained by agarose gel electrophoresis. On the other hand, plasmid

pUC 19 was completely digested with

SphI and

AccI, and ligated with T4 DNA ligase to the

SphI-

AccI fragment of pPD 302, after which

Escherichia coli JM 109 was transformed with this ligated plasmid. The trasformed strains were obtained

from an L-medium containing ampicillin, and bacterial reaction was conducted in the

same manner as described in Example 4, thereby obtaining transformed strains having

the ability to convert D-N-carbamoyl-parahydroxyphenylglycine into D-parahydroxyphenylglycine.

The plasmid contained in these transformed strains was named pPD 304. The plasmid

pPD 304 was prepared from the above transformed strains, followed by mapping, which

revealed that it had the structure shown in Fig. 4.

[0058] Escherichia coli JM 109 transformed with pPD 304 was named

Escherichia coli JM 109 pPD 304. The accession number given from the Fermentation Research Institute

was FERM BP-3183.

Example 6

[0059] Conversion of D-N-carbamoyl-α-amino acid into D-α-amino acid with enzyme obtained

from transformed strains:-

[0060] Using the plasmid pAD 108 obtained in Example 4,

Escherichia coli JM 109 was transformed. This strain was cultivated in L-broth containing 100 µg/ml

of ampicillin and 100 µg/ml of IPTG at 37°C for 16 hours. From 100 ml of this culture

solution, bacterial cells were harvested and then suspended in 0.1 M KPB (pH 7.0)

to the volume of 10 ml. This was subjected to ultrasonication while cooling with ice,

followed by centrifugation to give the supernatant as a crude enzyme solution. Using

this crude enzyme solution, reaction was conducted with various kinds of D-N-carbamoyl-α-amino

acid shown in Table 3 as a substrate. To 2 ml of 40 mM D-N-carbamoyl-α-amino acid

(Table 3) and 0.2 M KPB (pH 7.0), 100 µl of the above crude enzyme solution were added,

thereby allowing to react at 40°C for 20 minutes, and the amount of D-α-amino acid

produced was determined. The results are shown in Table 3. Moreover, there was a 10-fold

improvement in the specific activity of a D-N-carbamoyl-α-amino acid amidohydrolase

obtained from JM 109 pAD 108 at this time as compared with a crude enzyme solution

from

Agrobacterium species KNK 712 (FERM BP-1900).

Example 7

[0061] Conversion of D-N-carbamoyl-α-amino acid into D-α-amino acid with enzyme obtained

from transformed strains: -

[0062] Using the plasmid pPD 304 obtained in Example 5,

Escherichia coli JM 109 was transformed. From this strain, a crude enzyme solution was obtained in

the same manner as described in Example 6. Using this crude enzyme solution, reaction

was conducted in the same manner as described in Example 6. The results are shown

in Table 3. There was a 40-fold improvement in the specific activity of a D-N-carbamoyl-α-amino

acid amidohydrolase obtained from JM 109 pPD 304 at this time as compared with a crude

enzyme solution from

Pseudomonas sp. KNK 003A (FERM BP-3181).

Example 8

[0063] Conversion of D-N-carbamoyl-parahydroxyphenylglycine into D-parahydroxyphenylglycine

with enzyme obtained from transformed strains:-

[0064] Using the plasmid pAD 108 obtained in Example 4,

Escherichia coli JM 109 was transformed. This strain was cultivated in the same manner as described

in Example 6. From 100 ml of the culture solution, bacterial cells were harvested,

and washed with 0.1 M KPB (pH 7.0), after which they were suspended in 100 ml of 5%

D-N-carbamoyl-parahydroxyphenylglycine, 0.05% Triton® X-100, and 0.1 M KPB (pH 7.0),

followed by stirring at 40°C for 20 hours to cause reaction. The reaction mixture

thus obtained was subjected to centrifugation at 6000 rpm for 10 minutes to remove

the bacterial cells, and pH was decreased to 2.7 by addition of concentrated hydrochloric

acid, followed by adsorption on the cation exchange resin IR-120B (H

+ type) and elution with 5% NH

4OH. Then, the eluates were desalinized with IRC-84 (H

+ type) and decolorized with an AF resin. The decolorized solution was concentrated

to allow crystallization, and the deposited crystals were recrystallized from water

to give 3.8 g of white powder. These crystals exhibited the specific rotation [α]

D20 = -158 (C = 1, 1 N HCl), and gave a single spot on TLC, and the IR spectrum thereof

was in agreement with that of the D-parahydroxyphenylglycine standard.

Example 9

[0065] Preparation of fixed D-N-carbamoyl-α-amino acid amidohydrolase:-

[0066] After 200 ml of the culture solution obtained, in the same manner as described in

Example 6, from the strains of

Escherichia coli JM 109 transformed with pAD 108 was harvested, they were washed with 0.1 M KPB (pH

7.0), and suspended in 20 ml of 0.1 M KPB (pH 7.0), followed by ultrasonication of

the bacterial cells. This suspension of disintegrated bacterial cells was subjected

to centrifugation at 12000 rpm for 20 minutes to give the supernatant as a crude enzyme

solution. To this crude enzyme solution, 2 g of anion exchange resin Duolite A-568

equilibrated with 0.1 M KPB (pH 7.0) were added, and stirred at 4°C for 15 hours to

make the enzyme adsorbed thereon. To this solution, glutaraldehyde was added to have

a final concentration of 0.1%, and stirred for 1 hour, followed by cross-linking treatment,

after which the resin was collected by filtration and washed with 0.1 M KPB, resulting

in 2 g of fixed D-N-carbamoyl-α-amino acid amidohydrolase.

Example 10

[0067] Conversion of D-N-carbamoyl-parahydroxyphenylglycine into D-parahydroxyphenylglycine

with immobilized enzyme:-

[0068] Two grams of immobilized D-N-carbamoyl-α-amino acid amidohydrolase obtained in Example

9 were added to 100 ml of 2% D-N-carbamoyl-parahydroxyphenylglycine and 0.1 M KPB

(pH 7.0), and stirred at 40°C for 20 hours, while maintaining the pH at 7.0 by addition

of 1 N HCl, thereby causing reaction. After the reaction, the mixture was allowed

to stand, and the reaction mixture was collected by suction, afcer which the produced

amino acid was purified in the same manner as described in Example 8 to give 1.5 g

of D-parahydroxyphenylglycine.

Example 11

[0069] Analysis of DNA base sequence for the gene of enzyme derived from

Agrobacterium species KNK 712 (FERM BP-1900) and capable of converting D-N-carbamoyl-α-amino acid into

the corresponding D-α-amino acid:-

[0070] The plasmid pAD 108 containing the gene of a D-N-carbamoyl-α-amino acid amidohydrolase

(hereinafter referred to as amidohydrolase) derived from

Agrobacterium species KNK 712 (FERM BP-1900) was digested with restriction endonucleases

EcoRI and

HindIII (manufactured by Takara Shuzo Co., Ltd.), and a 1.8. kb DNA fragment was separated

for preparation by agarose gel electrophoresis. This fragment was digested with various

restriction endonucleases, and ligated with T4-DNA ligase (manufactured by Takara

Shuzo Co., Ltd.) to M13mp18 or M13mp19, after which

Escherichia coli JM 109 was infected therewith, resulting in the formation of a plaque. This single

plaque was inoculated into 1.5 ml of 2YT medium (16 g/l of bactotrypton (Difco Co.),

10 g/l of yeast extract (Difco Co.), and 5 g/l of NaCl) into which 1% JM 109 had been

inoculated, and subjected to shaking culture at 37°C for 5 hours. After centrifugation,

200 µl of 20% polyethyleneglycol 6000 and 25 M NaCl solution were added to the supernatant,

and allowed to stand at room temperature for 15 minutes, after which phage particles

were recovered as a precipitate by centrifugation. This was dissolved in 100 µl of

TE solution [10 mM Tris HCl (pH 8.0), 1 mM EDTA], and extracted with 50 µl of phenol

(saturated with TE solution), after which 10 µl of 3 M sodium acetate solution and

250 µl of ethanol were added and allowed to stand overnight at -20°C, followed by

centrifugation. After drying, the precipitate was dissolved in 50 µl of TE solution.

Then, 7 µl of this solution was used for reaction, electrophoresis, and autoradiography

with the aid of a DNA sequence kit (manufactured by United States Biochemical Corp.)

using SEQUENASE (registered trade mark) ver. 2, according to its instruction manual.

From the results obtained, the DNA base sequence of amidohydrolase gene for the strain

KNK 712 was determined as shown by SEQ ID No. 1 in the accompanying Sequence Listing.

Example 12

[0071] Analysis of DNA base sequence for the gene of enzyme derived from

Pseudomonas sp. KNK 003A (FERM BP-3181) and capable of converting D-N-carbamoyl-α-amino acid

into the corresponding D-α-amino acid:

[0072] The plasmid pPD 304 containing amidohydrolase gene derived from the strain KNK 003A

was digested with restriction endonucleases

BamHI and

HindIII (manufactured by Takara Shuzo Co., Ltd.), and a 1.8 kb DNA fragment was separated

for preparation by agarose gel electrophoresis. This fragment was digested with various

restriction endonucleases, and ligated with T4-DNA ligase (Takara Shuzo Co., Ltd.)

to M13mpl8 or M13mp19, after which

Escherichia coli JM 109 was infected therewith, resulting in the formation of a plaque. This single

plaque was inoculated into 1.5 ml of 2YT medium (16 g/l bactotrypton (Difco Co.),

10 g/l yeast extract (Difco Co.), and 5 g/l NaCl) into which 1% JM 109 had been inoculated,

and subjected to shaking culture at 37°C for 5 hours. After centrifugation, 200 µl

of 20% polyethyleneglycol 6000 and 25 M NaCl solution were added to the supernatant,

and allowed to stand at room temperature for 15 minutes, after which phage particles

were recovered as a precipitate by centrifugation. This was dissolved in 100 µl of

TE solution [10 mM Tris HCl (pH 8.0), 1 mM EDTA], and extracted with 50 µl of phenol

(saturated with TE solution), after which 10 µl of 3M sodium acetate solution and

250 µl of ethanol were added thereto, and allowed to stand overnight at -20°C, followed

by centrifugation. After drying, the precipitate was dissolved in 50 µl of TE solution.

Then, 7 µl of this solution was used for reaction, electrophoresis, and autoradiography

with the aid of a DNA sequence kit (manufactured by United States Biochemical Corp.)

using SEQUENASE (registered trade mark) ver. 2, according to its instruction mannual.

From the results obtained, the DNA base sequence of amidohydrolase gene derived from

the strain KNK 003A was determined as shown by SEQ ID No. 2 in the accompanying Sequence

Listing.

Example 13

[0073] Purification of D-N-carbamoyl-α-amidohydrolase derived from

Agrobacterium species KNK 712 (FERM BP-1900):-

[0074] Agrobacterium species KNK 712 (FERM BP-1900) was cultivated in the medium of Table 4 at 33°C for 25 hours.

Table 4

| Glycerin |

25 g |

| Sucrose |

5 g |

| KH2PO4 |

5 g |

| Na2HPO4 |

5 g |

| MgSO4.7H2O |

1 g |

| MnCl2.4H2O |

10 mg |

| Yeast extract |

4 g |

| Urea |

2 g |

| D-N-carbamoyl-P-hydroxyphenylglycine |

1 g |

| Water was added to the volume of 1 liter (pH 6.5). |

[0075] Water was added to the volume of 1 liter (pH 6.5).

[0076] Twenty one liters of this culture solution were harvested and the bacterial_cells

were ultrasonicated. After removal of the residue by centrifugation, nucleic acids

were removed by protamine sulfate treatment (0.1 mg/mg of protein). The centrifuged

supernatant was subjected to heat treatment at 50°C for 20 minutes, and after removal

of the precipitate, protein was precipitated by addition of ammonium sulfate, and

a protein fraction having activity and being precipitated with 15% to 35% saturated

ammonium sulfate was recovered. This fraction was dissolved and subjected to HPLC

using DEAE-5pw column (manufactured by Toso Co., Ltd.), followed by elution with a

concentration gradient of NaCl and recovered active fractions. At this stage, in comparison

with a suspension of disintegrated bacterial cells, there was about 20-fold increase

in the specific activity of amidohydrolase. When this fraction was analyzed by SDS-polyacrylamide

gel electrophoresis, this amidohydrolase migrated near to the position corresponding

to the molecular weight of about 35,000.

Example 14

[0077] Determination of amino acid sequence around protein amino terminus of D-N-carbamoyl-α-amino

acid amidohydrolase derived from

Agrobacterium species KNK 712 (FERM BP-1900):-

[0078] A purified amidohydrolase preparation produced by

Agrobacterium species KNK 712 (FERM BP-1900) obtained in Example 13 was charged in a_reverse-phase HPLC

column (AP-303; manufactured by YMC Co.), and eluted with a concentration gradient

of acetonitrile. This fraction containing the amidohydrolase was charged for analysis

in a gas-phase protein sequencer (manufactured by Applied Biosystems Co., Ltd.), and

it was found that the amidohydrolase is a protein having a sequence in the amino terminus

portion, which consists of 1st to 20th amino acids of SEQ ID No. 1 .

Example 15

[0079] Purification of D-N-carbamoyl-α-amino acid amidohydrolase derived from Pseudomonas

sp. KNK 003A (FERM BP-3181):-

[0080] Pseudomonas sp. KNK 003A (FERM BP-3181) was cultivated in the medium of Table 5 at

45°C for 3 days.

Table 5

| Glycerin |

10 g |

| Glucose |

5 g |

| KH2PO4 |

3.5 g |

| Na2HPO4 |

3.5 g |

| MgSO4.7H2O |

0.5 g |

| MnCl2.4H2O |

20 mg |

| FeSO4 |

10 mg |

| CaCO3 |

1 g |

| Meat extract |

2 g |

| Yeast extract |

2 g |

| Polypeptone |

2 g |

| D-N-carbamoylalanine |

1 g |

| Water was added to the volume of 1 liter (pH 7.0). |

[0081] Water was added to the volume of 1 liter (pH 7.0).

[0082] Twenty six liters of this culture solution were harvested, and in the same manner

as described in Example 13, the following operations were conducted: ultrasonication

of the bacterial cells; removal of nucleic acids by protamine sulfate treatment; heat

treatment (65°C, 20 min); fractionation by ammonium sulfate precipitation (separation

of protein fractions having amidohydrolase activity and being precipitated with 50%

to 70% saturated ammonium sulfate); and HPLC using DEAE-5pw column. These active fractions

was allowed to adsorb in a Biogel-HT (Bio-Rad Laboratories Co., Ltd.) column, and

eluted with a concentration gradient of ammonium sulfate, after which the active fractions

were concentrated and subjected to gel filtration using a Sephacryl® S-300 (Pharmacia

LKB Biotechnology Co., Ltd.) column.

[0083] Then, when isoelectric focusing (pH 4 to 6.5) was conducted, the above amidohydrolase

migrated near to the position at pH 5.7, and the gel of this band portion having activity

was cut out, from which protein was extracted. At this stage, in comparison with a

suspension of the disintegrated bacterial cells, there was about 100-fold increase

in the specific activity of amidohydrolase. When this sample was analyzed by SDS-polyacrylamide

gel electrophoresis, amidohydrolase migrated near to the position corresponding to

the molecular weight of about 38,000. Moreover, when this sample was subjected to

gel filtration using a Sephacryl® S-200 column, it was eluted at the position corresponding

to the molecular weight of about 67,000.

Example 16

[0084] Determination of amino acid sequence around protein amino terminus of D-N-carbamoyl-α-amino

acid amidohydrolase derived from

Pseudomonas sp. KNK 003A (FERM BP-3181):-

[0085] A purified amidohydrolase preparation from

Pseudomonas sp. KNK 003A (FERM BP-3181) obtained in Example 15 was charged in a reverse-phase

HPLC column, and eluted with a concentration gradient of acetonitrile. This fraction

containing the amidohydrolase was charged for analysis in a gas-phase protein sequencer,

and it was found that the amidohydrolase is a protein having a sequence in the amino

terminus portion, which consists of 1st to 20th amino acids of SEQ ID No. 2 .

Example 17

[0086] Purification of D-N-carbamoyl-α-amino acid amidohydrolase produced by transformed

Escherichia coli:-

[0087] Escherichia coli JM 109.pAD 108 obtained in Example 4 and

Escherichia coli JM 109.pPD 304 obtained in Example 5 were cultivated by the method as described in

Example 6. The bacterial cells were collected from each culture solution by centrifugation,

and ultrasonicated. After removal of the residue, these crude enzyme solutions were

analyzed by SDS-polyacrylamide electrophoresis. With respect to a suspension of the

cultivated and disintegrated bacterial cells of

Escherichia coli JM 109.pAD 108, the amidohydrolase migrated to the position corresponding to the

molecular weight of about 35,000, and an analysis by densitometer after staining revealed

that the amidohydrolase amounted to about 50% of the whole soluble proteins of the

bacterial cells. Moreover, with respect to a suspension of the cultivated and disintegrated

bacterial cells of

Escherichia coli JM 109.pPD 304, the amidohydrolase migrated to the position corresponding to the

molecular weight of about 38,000, and an analysis by densitometer after staining revealed

that the amidohydrolase amounted to about 15% of the whole soluble proteins of the

bacterial cells.

Example 18

[0088] Determination of protein amino terminal sequence of D-N-carbamoyl-α-amino acid amidohydrolase

produced by transformed

Escherichia coli:-

[0089] A suspension of the cultivated and disintegrated bacterial cells of

Escherichia coli JM 109.pAD 108 obtained in Example 17 was subjected to heat treatment at 50°C for

30 minutes, and after removal of the precipitate by centrifugation, ammonium sulfate

was added to give 30% saturation, thereby causing precipitation of protein. The precipitated

protein was removed by centrifugation and dissolved in deionized water, followed by

desaltization using an NAP-10 column (Pharmacia LKB Biotechnology Co., Ltd.) and charging

in a gas-phase protein sequencer. From the results obtained, it was found that there

were mixed proteins in approximately the same quantities, one having a sequence in

the amino terminus portion, which consists of 1st to 16th amino acids of SEQ ID No.

1, and the other having a sequence in the amino terminus portion, which contains an

additional methionine residue attached to the amino terminus of the former's sequence.

Effect of the invention

[0090] As described hereinabove, the present invention makes it possible to produce D-α-amino

acids from D-N-carbamoyl-α-amino acids with high efficiency by employing gene technology.

Brief Description of the drawings

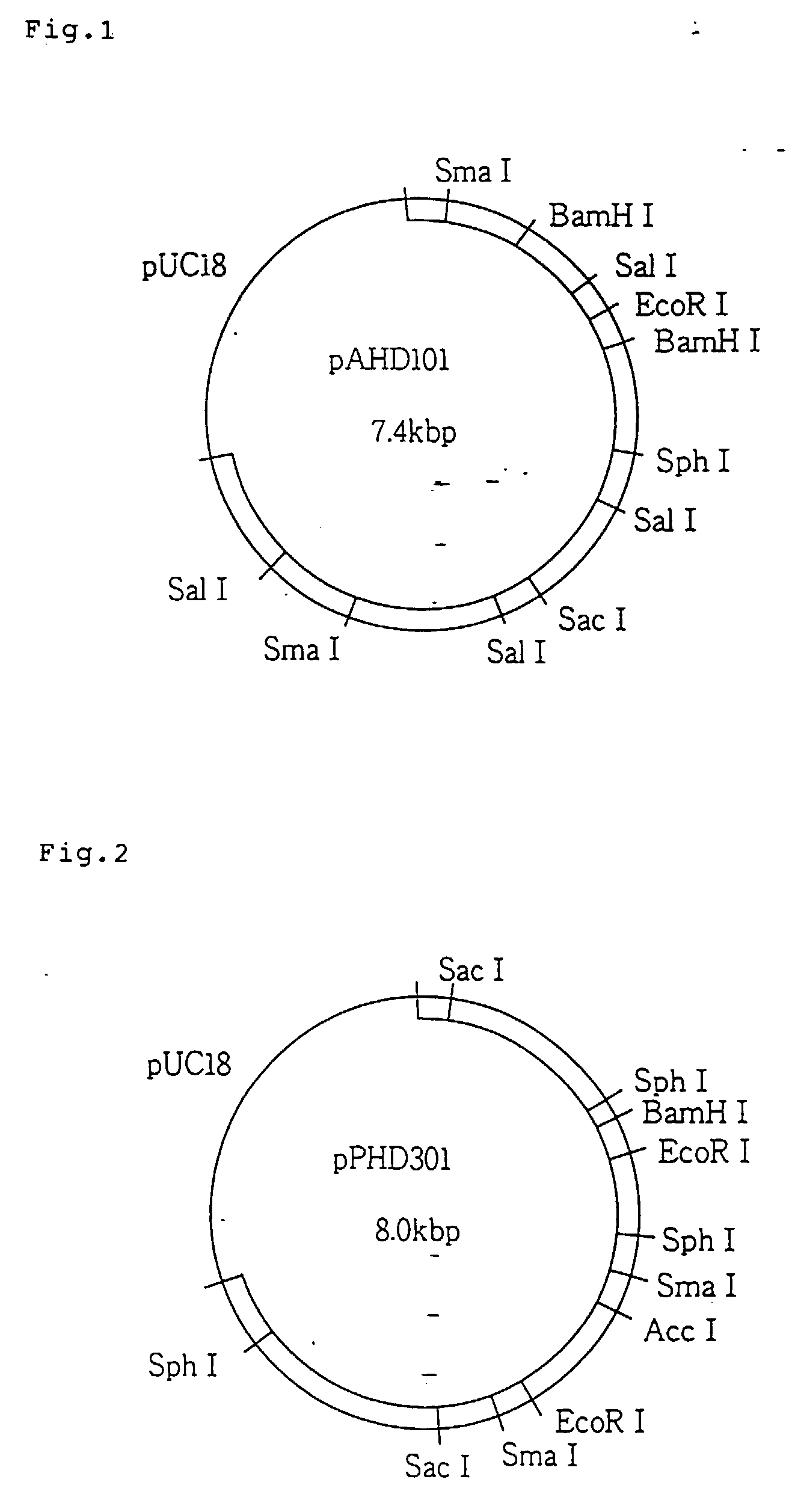

[0091] Fig. 1 shows the restriction endonuclease map of plasmid pAHD 101 obtained by the

present invention.

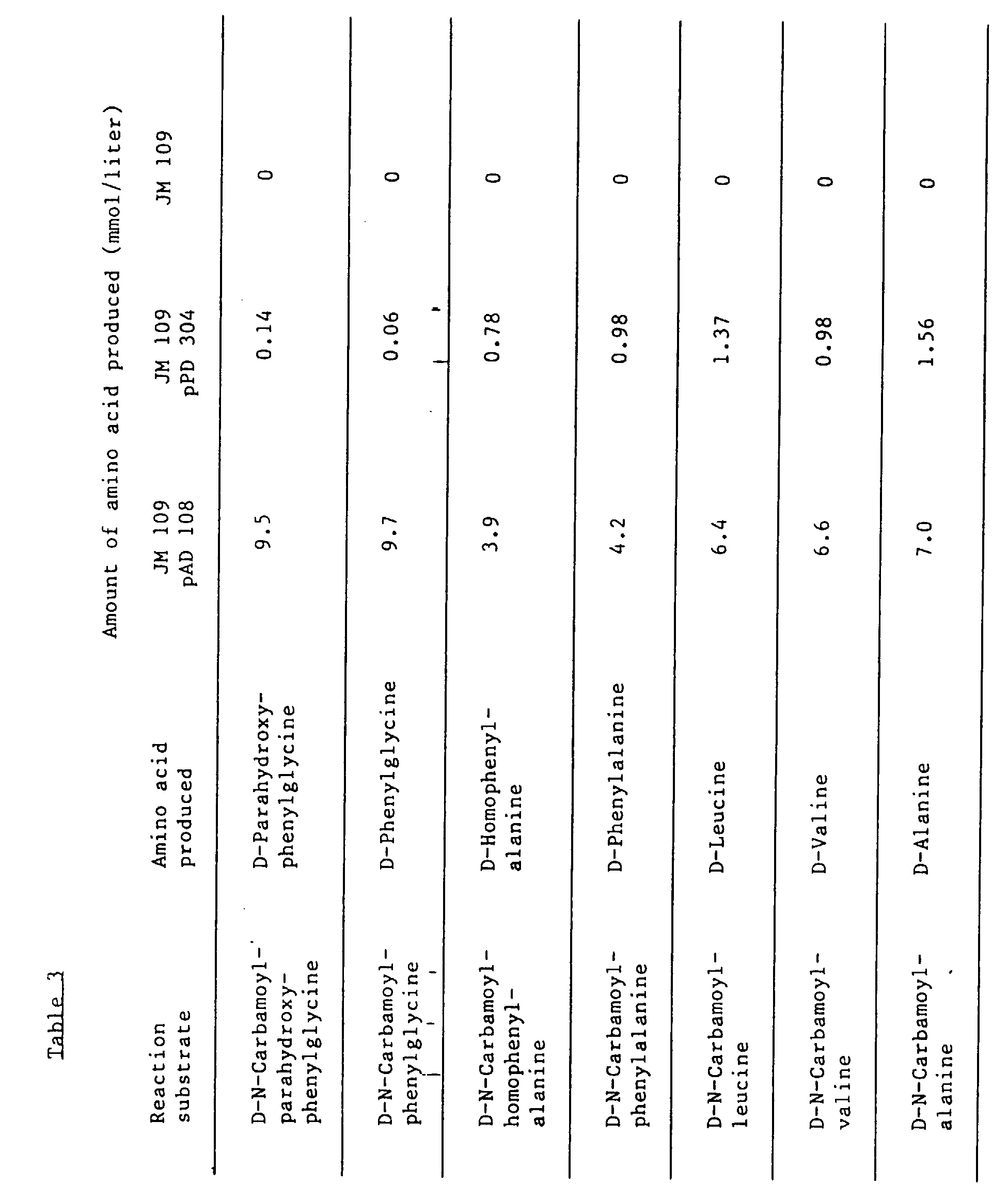

[0092] Fig. 2 shows the restriction endonuclease map of plasmid pPHD 301 obtained by the

present invention.

[0093] Fig. 3 shows the restriction endonuclease map of plasmid pAD 108 obtained by the

present invention.

[0094] Fig. 4 shows the restriction endonuclease map of plasmid pPD 304 obtained by the

present invention.

SEQUENCE LISTING

[0095]

SEQ ID NO.: 1

SEQUENCE LENGTH: 1785

SEQUENCE TYPE: nucleic acid

STRANDEDNESS: double

TOPOLOGY: linear

MOLECULE TYPE: genomic DNA

ORIGINAL SOURCE

ORGANISM: Agrobacterium species

STRAIN: KNK 712 (FERM BP-1900)

SEQ ID NO.: 2

[0097]

SEQUENCE LENGTH: 1820

SEQUENCE TYPE: nucleic acid

STRANDEDNESS: double

TOPOLOGY: linear

MOLECULE TYPE: genomic DNA

ORIGINAL SOURCE

ORGANISM: Pseudomonas sp.

STRAIN: KNK 003A (FERM BP-3181)

Claims for the following Contracting State(s): BE, DE, FR, GB, IT, NL

1. A process for the production of D-α-amino acids, by the method in which D-N-carbamoyl-α-amino

acids are converted into the corresponding D-α-amino acids in an aqueous medium with

the aid of an action of an enzyme capable of converting D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids, characterized

in that said enzyme is produced by a transformant which is obtainable by transformation

of host bacterial cells selected from microorganisms belonging to the genus Escherichia,Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium or Brevibacterium with a recombinant DNA comprising a vector DNA and a DNA fragment having a gene encoding

said enzyme, after which the D-α-amino acids produced are collected.

2. A process according to claim 1, wherein D-N-carbamoyl-α-amino acid is a compound of

the general formula:

R-CH(NHCONH2)-COOH

(where R is phenyl, phenyl substituted with hydroxy, alkyl, substituted alkyl, aralkyl,-or

thienyl).

3. A process according to claim 1 or 2, wherein the enzyme produced by the transformant

is present in a culture solution of said transformant, bacterial cells, treated bacterial

cells, extracts from bacterial cells, immobilized bacterial cells, or is used as a

immobilized enzyme.

4. A process according to any one of claims 1 to 3, wherein the DNA fragment containing

said gene is derived from eucaryotes, procaryotes, viruses, bacteriophages, or plasmids.

5. A process according to claim 4, wherein said procaryotes are bacteria.

6. A process according to claim 5, wherein said bacteria are those selected from microorganisms

belonging to the genus Pseudomonas, Agrobacterium, Aerobacter, Aeromonas, Brevibacterium, Bacillus, Flavobacterium, Serratia, or Micrococcus.

7. A process according to claim 6, wherein said bacteria are Pseudomonas sp. KNK 003A (FERM BP-3181) or Pseudomonas sp. KNK 505 (FERM BP-3182).

8. A process according to claim 6, wherein said bacteria are Agrobacterium species KNK 712 (FERM BP-1900).

9. A microorganism including a recombinant comprising a vector DNA and a DNA fragment

having a gene encoding an enzyme capable of converting D-N-carbamoyl-α-amino acids

into the corresponding D-α-amino acids.

10. A microorganism according to claim 9, wherein said microorganism including the recombinant

is one selected from microorganisms belonging to the genus Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium, or Brevibacterium.

11. A microorganism according to claim 10, wherein said microorganism is Escherichia coli JM 109 pAD 108 (FERM BP-3184), or Escherichia coli JM 109 pPD 304 (FERM BP-3183).

12. A process for the production of D-N-carbamoyl-α-amino acid amidohydrolases, characterized

in that a transformant which is obtained by transformation of host bacterial cells

selected from microorganisms belonging to the genus Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium, or Brevibacterium with a recombinant DNA comprising a vector DNA and a DNA fragment having a gene encoding

an enzyme capable of converting D-N-carbamoyl-α-amino acids by removal of their carbamoyl

groups into the corresponding D-α-amino acids is cultivated and said enzyme is recovered.

13. A process according to claim 12, wherein D-N-carbamoyl-α-amino acid is a compound

of the general formula:

R-CH(NHCONH2)-COOH

(where R is phenyl, phenyl substituted hydroxy, alkyl, substituted alkyl, aralkyl,

or thienyl).

14. A recombinant plasmid which is obtained by recombination of plasmid pUC 18 or pUC

19 with a DNA fragment having any one of the restriction endonuclease maps of Figs.

1-4 and containing an gene encoding a D-N-carbamoyl-α-amino acid amidohydrolase derived

from Pseudomonas sp. KNK 003A (FERM BP-3181) or Agrobacterium species KNK 712 (FERM BP-1900).

15. An immobilized enzyme in which an enzyme capable of converting D-N-carbamoyl-α-amino

acids by removal of their carbamoyl groups into the corresponding D-α-amino acids

is fixed on a support for immobilization capable of carrying the enzyme.

16. A gene for a protein having the enzyme activity to convert D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids, said

gene encoding all or a part of the amino acid sequence of 1st to 303rd amino acids

shown in SEQ ID No. 1 in the accompanying Sequence Listing.

17. A DNA fragment in which the base sequence of 167th to 232nd bases of SEQ ID No. 1,

or a base sequence equivalent thereto, is attached to the upstream of the 5' end of

the DNA fragment according to claim 16.

18. A DNA fragment having all or a part of the base sequence of 1st to 1785th bases of

SEQ ID No. 1, or having a base sequence equivalent thereto, and containing a gene

of a protein which has the enzyme activity to convert D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids.

19. A DNA fragment according to claim 18, which comprises a DNA fragment encoding the

amino acid sequence of 1st to 20th amino acids of SEQ ID No. 1.

20. A gene of a protein having the enzyme activity to convert D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids, said

gene encoding all or a part of the amino acid sequence of 1st to 311th amino acids

of SEQ ID No. 2.

21. A DNA fragment having the base sequence of 1st to 1820th bases of SEQ ID No. 2 , or

having a base sequence equivalent thereto, and containing a gene of a protein which

has the enzyme activity to convert D-N-carbamoyl-α-amino acids by removal of their

carbamoyl groups into the corresponding D-α-amino acids.

22. A DNA fragment according to claim 21, which comprises a DNA fragment encoding the

amino acid sequence of 1st to 20th amino acids of SEQ ID No. 2.

23. A protein having all or a part of the amino acid sequence of 1st to 303rd amino acids

of SEQ ID No. 1, and having the enzyme activity to convert D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids.

24. A protein according to claim 23, which has the amino acid sequence of 1st to 20th

amino acids of SEQ ID No. 1.

25. A protein having all or a part of the amino acid sequence of 1st to 311st amino acids

of SEQ ID No. 2, and having the enzyme activity to convert D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids.

26. A protein according to claim 25, which has the amino acid sequence of 1st to 20th

amino acids of SEQ ID No. 2.

27. A microorganism according to claim 9, wherein said vector DNA is a vector which can

autonomously grow in a cell of a microorganism belonging to the genus Escherichia.

28. A process for the production of a D-α-amino acid from a D-N-carbamoyl-α-amino acid

characterized in that an enzyme which removes carbamoyl group of the D-N-carbamoyl-α-amino

acid produced by the microorganism according to claim 9 or 27 to convert it into the

corresponding D-α-amino acid is used.

29. A process for the production of an enzyme for removing carbamoyl group of a D-N-carbamoyl-α-amino

acid to convert it into the corresponding D-α-amino acid characterized in that the

microorganism according to claim 9 or 27 is used.

30. A DNA fragment having all or a part of the base sequence of 230th to 1144th bases

shown in SEQ ID No. 1, or a base sequence equivalent thereto, and containing a gene

encoding a protein which has the enzyme activity to convert a D-N-carbamoyl-α-amino

acid by removal of its carbamoyl group into the corresponding D-α-amino acid.

31. A DNA fragment having all or a part of the base sequence of 233rd to 1141st bases

shown in SEQ ID No. 1, or a base sequence equivalent thereto, and containing a gene

encoding a protein which has the enzyme activity to convert a D-N-carbamoyl-α-amino

acid by removal of its carbamoyl group into the corresponding D-α-amino acid.

32. An expressible recombinant DNA comprising a DNA fragment according to claim 30 or

31 and a vector DNA.

33. A microorganism comprising a recombinant DNA according to claim 32.

34. A process for the production of an enzyme which removes carbamoyl group of a D-N-carbamoyl-α-amino

acid to convert it into the corresponding D-α-amino acid characterized in that a microorganism

according to claim 33 is used.

35. A process for the production of a D-α-amino acid from a D-N-carbamoyl-α-amino acid

characterized in that an enzyme produced by a process according to claim 34 is used.

36. An immobilized enzyme obtained by immobilizing a protein according claim 23 on an

immobilized support.

37. A process for the production of a D-α-amino acid from a D-N-carbamoyl-α-amino acid

characterized in that a protein of claim 23 or an enzyme of claim 36 is used.

38. Use of a protein having decarbamylase activity according to claim 23 for the production

of a D-α-amino acid.

39. Use of an immobilized enzyme according to claim 36 for the production of a D-α-amino

acid.

Claims for the following Contracting State(s): ES

1. A process for the production of D-α-amino acids, by the method in which D-N-carbamoyl-α-amino

acids are converted into the corresponding D-α-amino acids in an aqueous medium with

the aid of an action of an enzyme capable of converting D-N-carbamoyl-α-amino acids

by removal of their carbamoyl groups into the corresponding D-α-amino acids, characterized

in that said enzyme is produced by a transformant which is obtainable by transformation

of host bacterial cells selected from microorganisms belonging to the genus Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium or Brevibacterium with a recombinant DNA comprising a vector DNA and a DNA fragment having a gene encoding

said enzyme, after which the D-α-amino acids produced are collected.

2. A process according to claim 1, wherein D-N-carbamoyl-α-amino acid is a compound of

the general formula:

R-CH(NHCONH2)-COOH

(where R is phenyl, phenyl substituted with hydroxy, alkyl, substituted alkyl, aralkyl,

or thienyl).

3. A process according to claim 1 or 2, wherein the enzyme produced by the transformant

is present in a culture solution of said transformant, bacterial cells, treated bacterial

cells, extracts from bacterial cells, immobilized bacterial cells, or is used as an

immobilized enzyme.

4. A process according to any one of claims 1 to 3, wherein the DNA fragment containing

said gene is derived from eucaryotes, procaryotes, viruses, bacteriophages, or plasmids.

5. A process according to claim 4, wherein said - procaryotes are bacteria.

6. A process according to claim 5, wherein said bacteria are those selected from microorganisms

belonging to the genus Pseudomonas, Agrobacterium, Aerobacter, Aeromonas, Brevibacterium, Bacillus, Flavobacterium,

Serratia, or Micrococcus.

7. A process according to claim 6, wherein said bacteria are Pseudomonas sp. KNK 003A (FERM BP-3181) or Pseudomonas sp. KNK 505 (FERM BP-3182).

8. A process according to claim 6, wherein said bacteria are Agrobacterium species KNK 712 (FERM BP-1900).

9. A process for preparing a microorganism comprising the step of including a recombinant

comprising a vector DNA and a DNA fragment having a gene encoding an enzyme capable

of converting D-N-carbamoyl-α-amino acids into the corresponding D-α-amino acids.

10. A process according to claim 9, wherein said microorganism including the recombinant

is one selected from microorganisms belonging to the genus Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium or Brevibacterium.

11. A process according to claim 10, wherein said microorganism is Escherichia coli JM 109 pAD 108 (FERM BP-3184) or Escherichia coli JM 109 pPD 304 (FERM BP-3183).

12. A process for the production of D-N-carbamoyl-α-amino acid amidohydrolases, characterized

in that a transformant which is obtained by transformation of host bacterial cells

selected from microorganisms belonging to the genus Escherichia, Pseudomonas, Flavobacterium, Bacillus, Serratia, Corynebacterium or Brevibacterium with a recombinant DNA comprising a vector DNA and a DNA fragment having a gene encoding

an enzyme capable of converting D-N-carbamoyl-α-amino acids by removal of their carbamoyl

groups into the corresponding D-α-amino acids is cultivated and said enzyme is recovered.

13. A process according to claim 12, wherein D-N-carbamoyl-α-amino acid is a compound

of the general formula:

R-CH(NHCONH2)-COOH

(where R is phenyl, phenyl substituted hydroxy, alkyl, substituted alkyl, aralkyl,

or thienyl).

14. A process of preparing a recombinant plasmid comprising the step of recombining plasmid

pUC 18 or pUC 19 with a DNA fragment having any one of the restriction endonuclease

maps of Figs. 1-4 and containing a gene encoding a D-N-carbamoyl-α-amino acid amidohydrolase

derived from Pseudomonas sp. KNK 003A (FERM BP-3181) or Agrobacterium species KNK 712 (FERM BP 1900).

15. A process for preparing an immobilized enzyme in which an enzyme capable of converting

D-N-carbamoyl-α-amino acids by removal of their carbamoyl groups into the corresponding

D-α-amino acids is fixed on a support for immobilization capable of carrying the enzyme.

16. A process for preparing a gene for a protein having the enzyme activity to convert

D-N-carbamoyl-α-amino acids by removal of their carbamoyl groups into the corresponding

D-α-amino acids, said gene encoding all or a part of the amino acid sequence of 1st

to 303rd amino acids shown in SEQ ID No. 1, comprising the step of isolating said

gene from Pseudomonas sp. KNK 003A (FERM BP-3181) or Agrobacterium species KNK 712 (FERM BP-1900).

17. A process for preparing a DNA fragment comprising the step of attaching the base sequence

of 167th to 232nd bases of SEQ ID No. 1, or a base sequence equivalent thereto to

the upstream of the 5' end of the DNA fragment according to claim 16.

18. A process for preparing a DNA fragment comprising the step of isolating a DNA sequence,

having all or a part of the base sequence of 1st to 1785th bases of SEQ ID No. 1,

or having a base sequence equivalent thereto, and containing a gene of a protein which

has the enzyme activity to convert D-N-carbamoyl-α-amino acids by removal of their

carbamoyl groups into the corresponding D-α-amino acids.

19. A process according to claim 18, which comprises a DNA fragment encoding the amino

acid sequence of 1st to 20th amino acids of SEQ ID No. 1.

20. A process for preparing a gene of a protein having the enzyme activity to convert

D-N-carbamoyl-α-amino acids by removal of their carbamoyl groups into the corresponding

D-α-amino acids, said gene encoding all or a part of the amino acid sequence of 1st

to 311th amino acids of SEQ ID No. 2 comprising the step of isolating said gene from

Pseudomonas sp. KNK 003A (FERM BP-3181) or Agrobacterium species KNK 712 (FERM BP 1900).

21. A process for preparing a DNA fragment, having the base sequence of 1st to 1820th

bases of SEQ ID No. 2, or having a base sequence equivalent thereto, and containing

a gene of a protein which has the enzyme activity to convert D-N-carbamoyl-α-amino

acids by removal of their carbamoyl groups into the corresponding D-α-amino acids,

comprising the step of isolating said DNA sequence.