| (19) |

|

|

(11) |

EP 1 308 391 A1 |

| (12) |

EUROPEAN PATENT APPLICATION |

| (43) |

Date of publication: |

|

07.05.2003 Bulletin 2003/19 |

| (22) |

Date of filing: 23.09.2002 |

|

| (51) |

International Patent Classification (IPC)7: B65D 1/22 |

|

| (84) |

Designated Contracting States: |

|

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR IE IT LI LU MC NL PT SE SK TR |

|

Designated Extension States: |

|

AL LT LV MK RO SI |

| (30) |

Priority: |

31.10.2001 IT MO20010210

|

| (71) |

Applicant: Sercom Srl. |

|

40014 Crevalcore (Bologna) (IT) |

|

| (72) |

Inventor: |

|

- Bonaveri, Germano

40026 Imola (Bologna) (IT)

|

| (74) |

Representative: Dalle Nogare, Roberto |

|

c/o Ufficio Internazionale Brevetti

INIP

Via Ruggi, 5

40137 Bologna

40137 Bologna (IT) |

|

| |

|

| (54) |

Metallic box to be made by an only plate sheet |

(57) A metallic box is provided, consisting of a bottom (1) and of four sides (2,3), realized

in an only piece; the assembling of the box is quickly realized manually by folding

the sides along folding lines, whereby the reciprocal bond is actuated in the final

part of the folding by retaining and blocking elements (6,8) of the contiguous sides,

said elements making part of the only produced piece.

|

|

[0001] In the production of the metallic boxes some factors weigh on the cost of the same

box and on which of the furniture of that this box is part. An important cost element

for the furniture producer is given by the box encumbered volume during the forwarding,

the moving and the storage. The optimum solution from this point of view is that the

box, during these phases, was substantially shaped to plane plate with its final shape

to be realized only in the use moment or when the box is to be mounted inside the

furniture. The constraint way of the sides between them is another determining cost

element. According to some prior art solutions screws, rivets or weldings are used,

or other additional elements to be specifically produced are used. Other known solutions

provide elements to be plastically folded in running like keys or other to realize

the connections. In the present art is not known a solution which gave a connection

of the sides where the only work to be made for the mounting was the folding of the

four sides for plastic deformation and the bond is directly actuated between the folded

sides without other elements to be added or without further plastic deformation workings.

The present invention refers to a metallic box the working out of which, consisting

of the bottom and of the four sides, is realized in an only piece. Moreover its assembling

is quickly realized also manually for folding of plastic type of the sides longways

the facilitated folding lines and where the reciprocal bond is actuated in the final

part of the folding making to correspond the retaining and the blocking elements of

the contiguous sides, said elements making part of the only produced piece. The present

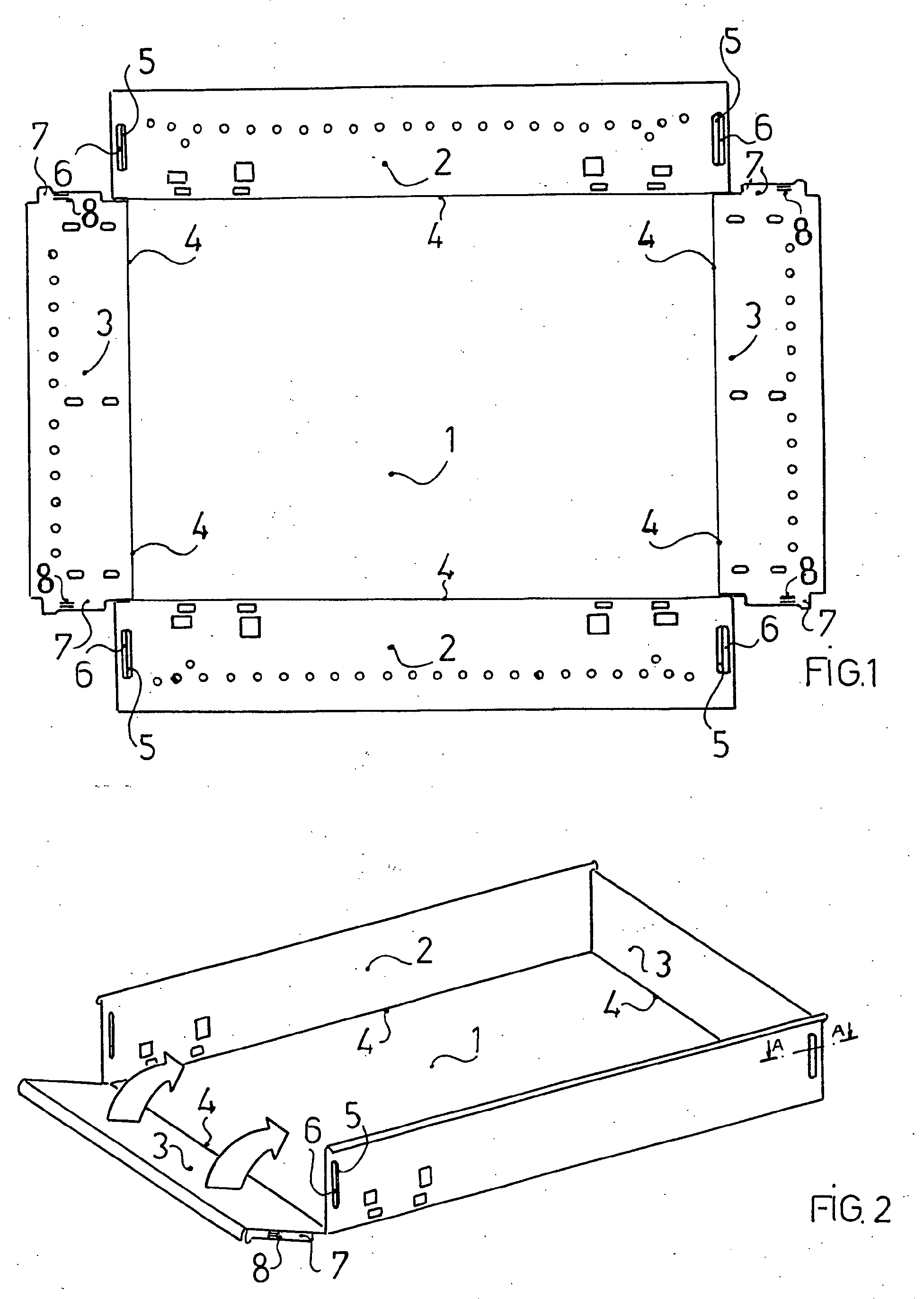

invention is better explained in the four figures of sheets 1 and 2 where is shown

a preferred embodiment. Figure 1 is plan view of the box after the production phase.

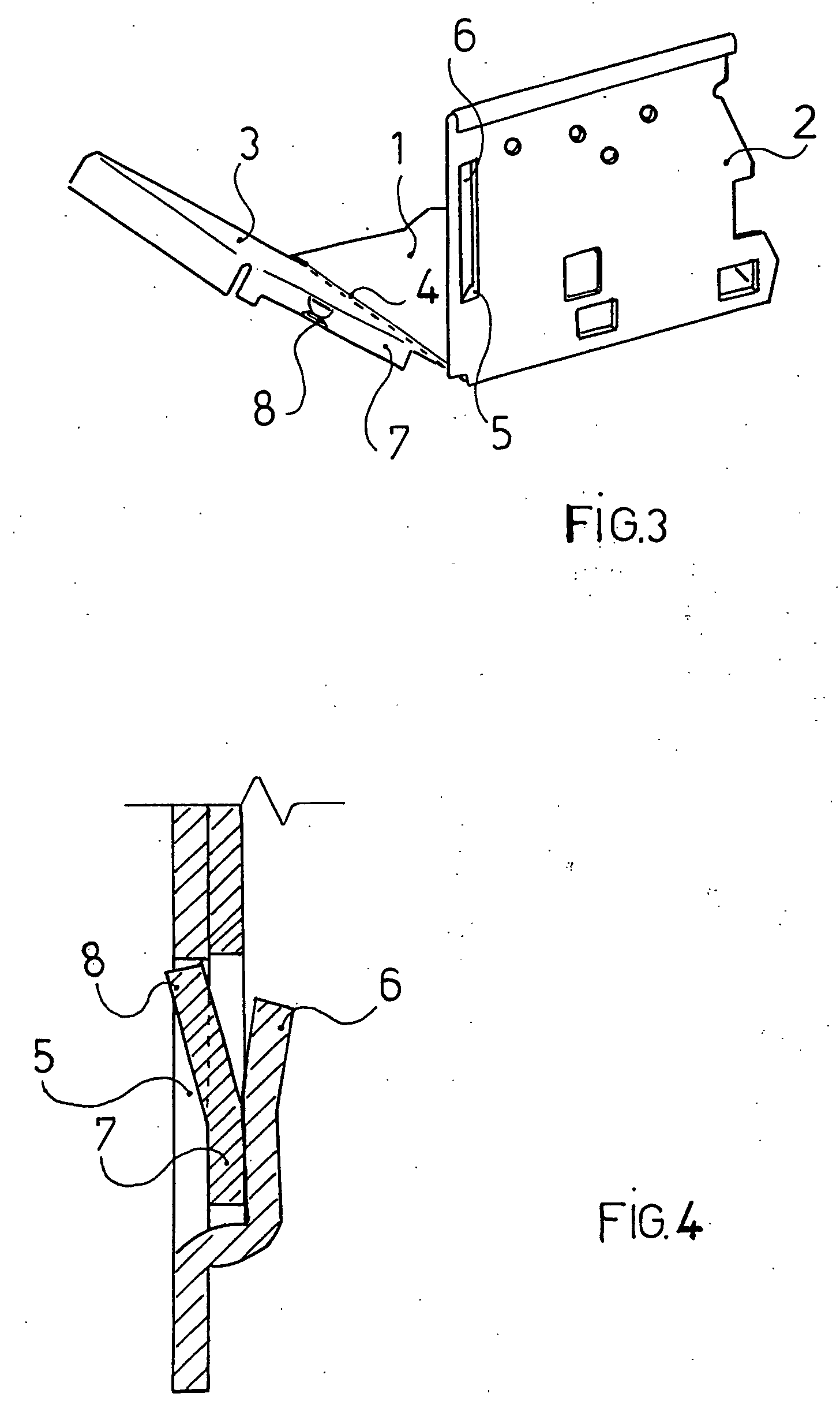

Figure 2 is view of the box with three sides already folded and bond between them

with the fourth side during the folding phase.

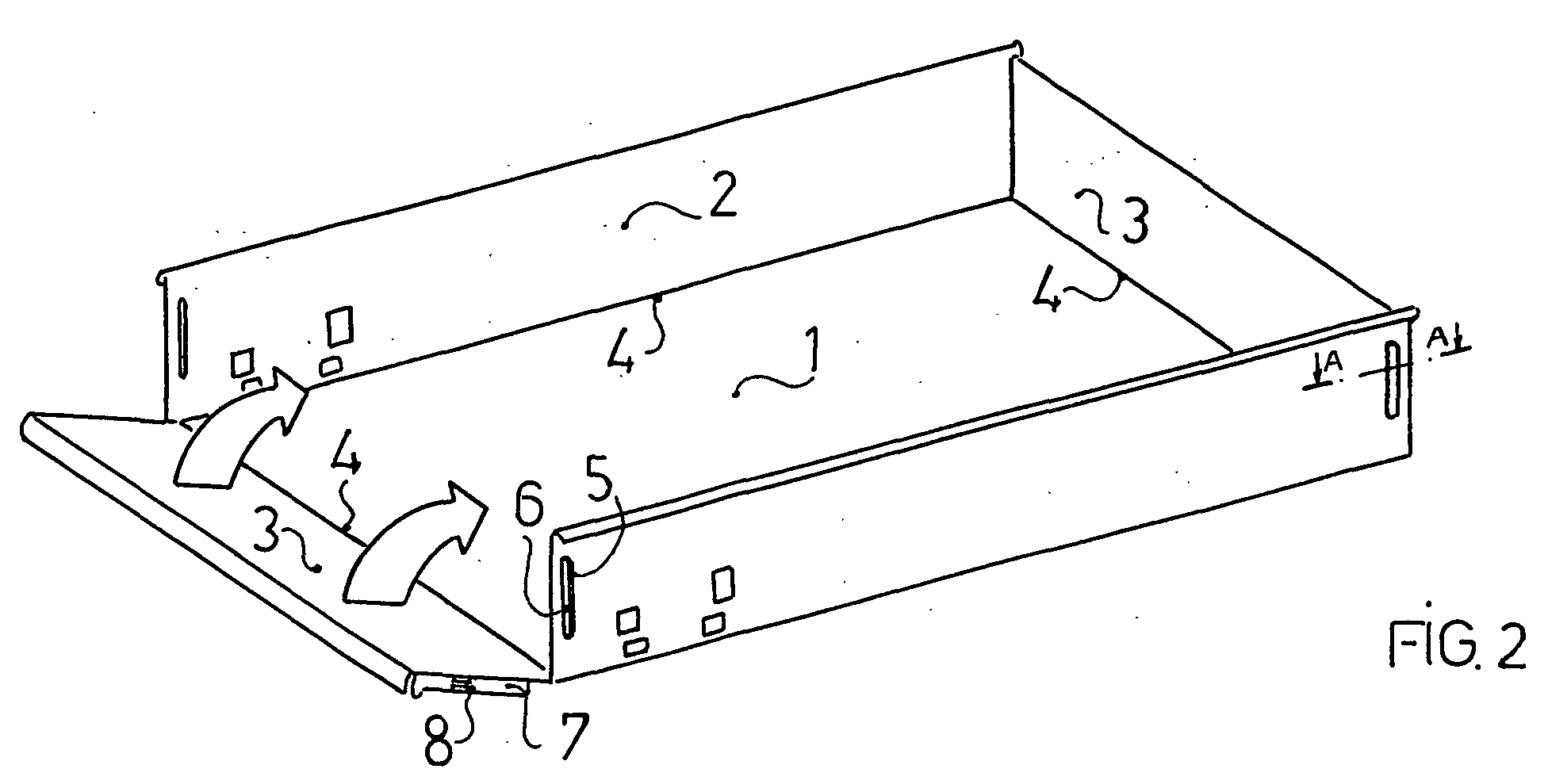

[0002] Figure 3 is view of a detail where the bond elements between the two contiguous sides

are pointed out. Figure 4 is view of the section A-A of figure 2 to show in other

detail the elements to realize the retaining and the blocking. The illustrated embodiment,

showing a concrete example, is realized for shearing and die forming. In figure 1

is to be noted the foundamental elements. The bottom 1, two opposite sides 2 each

of them having near their ends two blocking openings 5 and two holding rims 6, two

opposite sides 3 having a holding reed 7 and a blocking component 8, facilitated folding

lines 4 between the bottom and each of the f-our sides. Said lines to be realized

by microshearing, hemming, line cut or other on condition that was realized the end

to locally reduce the resistance to the plastic deformation necessary for the folding.

In the drawings are to be noted also drillings and various openings suitable for the

connection with guide bearing and other parts. The assembling phase, illustrated in

figures 2 and 3, begins with the folding longways the facilitated folding lines of

the two opposite sides 2 that are placed at 90° in comparison with the bottom. At

the second step one of the two sides 3 is brought in folding. Near the 90° the male

holding reeds 7 of the side begin to engage with the correspond ing holding rims 6

of the contiguous sides 2 that with the concurrent action of the inside face of the

side form the female part. From the figures 3 and 4 is to be noted that shortly before

the reed 7 reachs the movement limit inside the rim 6, a male blocking component 8,

to be realized by semishearing on the side 3, meets a female blocking element consisting

of an opening 5 into which the male component 8 comes to engage realizing a bond that

blocking all movements. In the same way, the other side 3, that in figure 2 is in

folding, is folded till the holding and the blocking with the contiguous sides 2.

In the illustrated embodiment the position of the holding and blocking elements is

so that the movement which determines the bond must be a "reopen" movement. In other

words the side 3 is folded over the 90° till the reed 7 has interely got over the

rim 6 and it is able to insert into the same rim with an opposite e direction movement.

This particular holding and blocking way has the advantage of a better resistance

to forces that tend to open the box such as against said forces acts the direct contact

between the end of the reed and the end of the rim (see figure 4). In the case that

different necessities make to be inclined for a direct blocking during the closing

phase, the positions of the holding and blocking elements have opposed orientation

in comparison with that illustrated so to reach holding and blocking during the closing

of the side 3.

[0003] To complete the description it is to be noted that the shape of the holding and blocking

elements illustrated not limiting the possibility to realized the invented box with

other shapes of these details and with different positions.

[0004] For. example the blocking opening 5 and the holding rim 6 may be separated instead

of realized with the same semi shearing. In the same way also the reed 7 and the.

male blocking component 8. may be separated instead of be realized with the same semi

shearing. Moreover the holding male elements 7 may be realized on the sides 2 that

are for first, folded and the holding female elements 6 may be realized onto the contiguous

sides (3). In the same way the male blocking elements 8 may be realized onto the sides

2 for first folded and the female blocking elements 5 on to the contiguous sides 3.

1. Metallic box to be made by an only plate sheet, on the base . of what previous described,

comprising a bottom, four sides and facilitated folding lines between the bottom and

the same sides, where the final shape of the box is realized for folding of the sides

longways the same facilitated folding lines and where each side is bonded with each

contiguous side by the retaining reciproc action of a male element presents' on a

side and a female - element presents on the other side., and the reciproc blocking

action between a male element provides on a side and a female element presents on

the other.

2. Metallici box to be made by an only plate sheet, as for claim 1, characterized in that for the holding and blocking actions between the contiguous sides, the small necessary

deformations permit to the same to be in the elastic characteristic of the material.

3. Metallic box to be made by an only plate sheet, as for the previous claims, in that

the holding and blocking phase is actuated during the' "reopen" movement of each of

the counterposed sides folded by last after that these are being folding over the

blocking position.

4. Metallic box to be made by an only plate sheet, as for the previous claims, characterized in that already during, the die forming is possible to realized openings with different shapes

so to fix guides or other parts.