| (19) |

|

|

(11) |

EP 0 928 874 B1 |

| (12) |

EUROPEAN PATENT SPECIFICATION |

| (45) |

Mention of the grant of the patent: |

|

09.06.2004 Bulletin 2004/24 |

| (22) |

Date of filing: 17.06.1998 |

|

| (51) |

International Patent Classification (IPC)7: E06B 3/46 |

|

| (54) |

Matching device for profiled sections of sliding doors or windows in a frame

Kollaborationsanordnung für Profile von Schiebefenstern oder -türen in einer Umrahmung

Disposition coopérante pour profilés de fenêtres ou portes coulissantes dans un encadrement

|

| (84) |

Designated Contracting States: |

|

ES FR GR PT |

|

Designated Extension States: |

|

AL MK |

| (30) |

Priority: |

09.01.1998 IT MI980018

|

| (43) |

Date of publication of application: |

|

14.07.1999 Bulletin 1999/28 |

| (73) |

Proprietor: ALL.CO S.p.A. |

|

I-56014 Ospedaletto (Pisa) (IT) |

|

| (72) |

Inventor: |

|

- Vecoli, Luigi

55045 Pietrasanta (Lucca) (IT)

|

| (74) |

Representative: Siniscalco, Fabio et al |

|

Jacobacci & Partners S.p.A.

Via Senato, 8

20121 Milano

20121 Milano (IT) |

| (56) |

References cited: :

DE-U- 1 895 317

US-A- 3 432 966

|

GB-A- 1 496 507

US-A- 4 185 416

|

|

| |

|

|

|

|

| |

|

| Note: Within nine months from the publication of the mention of the grant of the European

patent, any person may give notice to the European Patent Office of opposition to

the European patent

granted. Notice of opposition shall be filed in a written reasoned statement. It shall

not be deemed to

have been filed until the opposition fee has been paid. (Art. 99(1) European Patent

Convention).

|

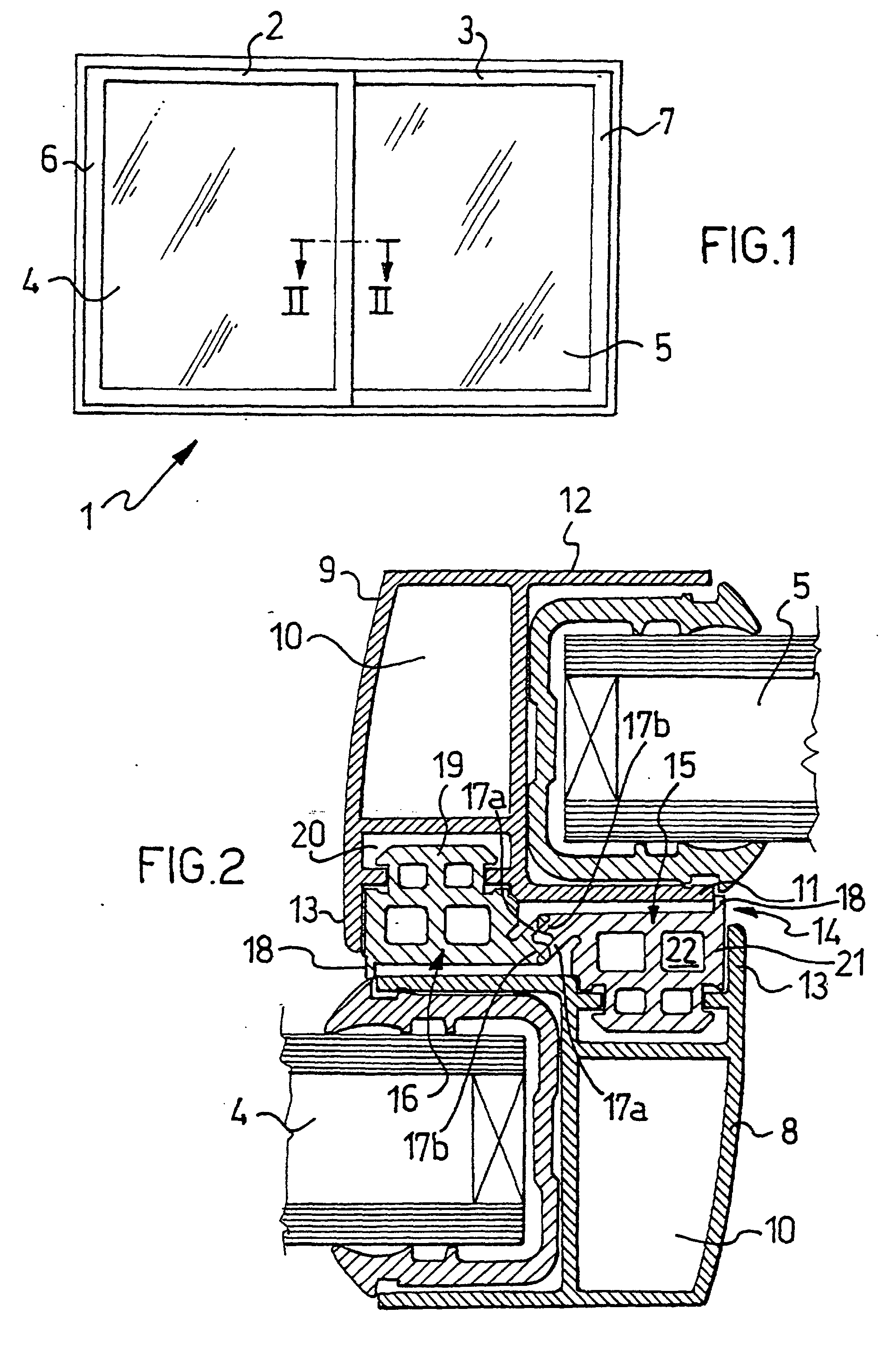

[0001] The present invention relates to a matching device for profiled sections of sliding

doors or windows when they are in the closed position in a frame.

[0002] As is known, in frames with sliding doors or' windows, there is a need to provide

a matching device between the profiled sections of the sliding doors or windows when

they are in the closed position. This matching device has to ensure leaktightness

between the doors or windows in the closed position.

[0003] US 4,185,416 discloses a weatherstrip for sealing the meeting stiles of a sliding

door, wherein the weather strip comprises two elongated weatherstrip members with

a rigid base section fixedly secured to the stile and a first flexible leg for resiliently

engaging a corresponding leg of the opposed weatherstrip member and a second resilient

leg for sealing against the sides of the meeting stile.

[0004] US 3,432,966 discloses a plastic interlock and weather seal strip for application

to sliding doors and windows, comprising a rigid hollow mounting and interlock portion

and a coextruded soft tubular weather seal portion in order to provide an interlocking

weather seal.

[0005] DE 18 95 317 U discloses a sliding window comprising elastic sealing profiles which

adhere one another in the closed position of the window. A sealing lip of the sealing

profiles has an at least partially hollow configuration.

[0006] GB 1 496 507 discloses a sliding contact packing comprising a resilient flexible

backing lip and a flexible substantially non-resilient low friction sheet of material

different from that of the backing lip. The sheet of low friction material is interposed

between the resilient flexible backing lip and the surface which is engaged by the

contact packing.

[0007] Nevertheless, the cited prior art solutions are still not sufficiently thermal insulating

and show a poor shape stability of the weather seal portions.

[0008] In accordance with a known solution, a matching device comprises a labyrinth formed

between shaped portions of the profiled sections of the doors or windows of the frame

when they are in the closed position and weatherstrips disposed along the labyrinth.

[0009] This solution is structurally complex since it requires profiled sections of complex

shape and, moreover, is unsatisfactory from the point of view of thermal insulation

since the labyrinth and the weatherstrips arranged as barriers together have high

thermal conductivity.

[0010] Matching devices in which strips of a suitable material are associated with the profiled

sections to form the labyrinth and suitable weatherstrips are arranged as barriers

for the labyrinth have been proposed. This solution achieves a definite improvement

in thermal insulation but has undoubted structural complexity owing to the presence

of the strips.

[0011] The problem upon which the present invention is based is that of devising a matching

device of the type specified which has structural and functional characteristics such

as to overcome the aforementioned problems.

[0012] This problem is solved by a matching device of the type specified comprising two

profiled strips, each of which is associated with a respective profiled section and

which are in mutual contact under pressure, the profiled strips having the features

defined in claim 1.

[0013] Further characteristics and the advantages of the present invention will become clear

from the following description of a preferred embodiment thereof, given by way of

non-limiting example, with reference to the appended drawings, in which:

Figure 1 is a schematic elevational view of a window frame incorporating a matching

device according to the present invention, and

Figure 2 is a view of the matching device of Figure 1, sectioned on the line II, and

on an enlarged scale.

[0014] With reference to the appended drawings, a frame which, in the embodiment shown,

is a window frame, is generally indicated 1. The window frame 1 includes two sliding

windows 2 and 3 which have respective double panes 4 and 5 enclosed in respective

frames 6 and 7. The frames 6 and 7 are made of profiled sections and comprise, in

particular, respective profiled sections 8 and 9 which are intended to meet when the

windows 2 and 3 are in the closed position in the window frame.

[0015] The profiled sections 8 and 9 are identical and are arranged in opposed positions.

[0016] Each profiled section comprises a box-like body 10 projecting from which there are

two flanges 11 and 12 holding the respective double pane, and a transverse flange

13.

[0017] The window frame 1 comprises a matching device 14 for the profiled sections 8 and

9 of the windows 2 and 3 when the windows are in the closed position.

[0018] The matching device 14 according to the invention comprises two profiled strips,

indicated 15 and 16, respectively, each associated with a respective profiled section

8 or 9.

[0019] When the sliding windows 1 and 3 are in the closed position in the frame 1, the two

profiled strips 15 and 16 of the matching device 14 are in mutual leaktight contact

under pressure.

[0020] The two profiled strips 15 and 16, which are identical and arranged in opposed positions,

are made of a thermally-insulating plastics material selected from elastomers constituted

by ethylene and propylene copolymers, such as DUTRAL (registered trade mark) and/or

similar materials.

[0021] Each profiled strip 15 (16) comprises a resiliently yielding lip 17a which is in

contact under pressure with a flat portion 17b of the other profiled strip 16 (15).

[0022] Each profiled strip 15 (16) associated with a profiled section 8 (9) advantageously

also comprises a resiliently yielding edging 18 which is in leaktight contact under

pressure with the transverse flange 13 of the other profiled section 9 (8).

[0023] At this point, it is easy to see that the matching device 14 according to the present

invention has, altogether, four leaktight pressure contact points, more precisely,

two leaktight pressure contacts between the edging 18 of the profiled strip carried

by each profiled section and the flange 11 of the other profiled section and two leaktight

pressure contacts between the lip 17a of each profiled strip and the flat portion

17b of the other profiled strip.

[0024] Each profiled strip 15, 16 of the matching device 14 is firmly fixed to the respective

profiled section 8 or 9 of the window by virtue of the fact that each profiled strip

15, 16 comprises a substantially mushroom-shaped appendage 19 which is engaged in

the manner of a press stud in a hammer-shaped recess 20 in the profiled section 8,

9.

[0025] Each profiled strip 15 or 16 has a body 21 with a substantially rectangular cross-section

which is housed between the box-like body 10 and the transverse flange 13 of the respective

profiled section. The appendage 19 projects from the body 21 towards the box-like

body 10, and the lip 17a and the flat portion 17b project from the body 21 towards

the transverse flange 13 of the other profiled section.

[0026] Each profiled strip 15 or 16 advantageously comprises a plurality of weight-reducing

cavities, all indicated 22, which, preferably, are of square cross-section and are

formed in the body 21 so as to confer on the cross-section of the profiled strip a

substantially cross-walled configuration, achieving low thermal conductivity.

[0027] The main advantage of the matching device according to the present invention lies

in its structural simplicity. It is in fact formed by few parts and allows the profiled

sections of the windows to be formed with a simple shape.

[0028] A further advantage of the matching device according to the present invention is

that it improves thermal insulation by virtue of the fact that the same elements which

ensure leaktightness also constitute a thermal break.

[0029] Finally, it should be noted that the matching device according to the present invention

can be installed quickly since the individual profiled strips which make up the matching

device are identical and can be fitted directly by the engagement of their appendages

in the manner of press studs in the recesses in the profiled sections.

[0030] Not the least advantage of the matching device according to the present invention

lies in its compactness. Moreover, it can be produced with an aesthetically pleasing

appearance.

[0031] Furthermore, it should be noted that the matching device according to the present

invention can be expected to have a practically indefinite operative life.

[0032] Naturally, in order to satisfy contingent and specific requirements, an expert in

the art may apply to the above-described device many modifications and variations

all of which, however, are included in the scope of protection of the invention as

defined by the following claims.

1. A matching device (14) for profiled sections (8, 9) of a sliding door or window (2,

3) when they are in the closed position in a frame (1), said matching device (14)

comprising two profiled strips (15, 16) each of which is associatable with a respective

profiled section (8, 9), the profiled strips (15, 16) being in mutual contact under

pressure when the door or window (2, 3) is brought into a closed position, the profiled

strips (15, 16) comprising a body (21) and being made of a thermally insulating material,

characterized in that the body (21) of the strips (8, 9) comprise a plurality of weight reducing cavities

(22) such that the cross-section of the profiled strips (15, 16) has a cross-walled

configuration achieving low thermal conductivity.

2. A matching device (14) according to Claim 1, characterized in that the two profiled strips (15, 16) are identical.

3. A matching device (14) according to Claim 1, characterized in that each profiled strip (15, 16) comprises a resiliently yielding lip (17a) which is,

in the closed position of the doors or windows (2, 3), in contact under pressure with

a portion (17b) of the other profiled strip (16, 15).

4. A matching device (14) according to Claim 3, characterized in that the profiled strip (15, 16) associatable with the profiled section (8, 9) of a door

or window (2, 3) comprises a resiliently yielding edge (18) which is, in the closed

position of the doors or windows (2, 3), in contact under pressure with the profiled

section ( 9 , 8) of the other door or window (3, 2).

5. A matching device (14) according to Claim 4, characterized in that each profiled strip (15, 16) comprises an appendage (19) which is engageable in a

recess (20) formed in the respective profiled section (8, 9).

6. A matching device (14) according to Claim 5, characterized in that the appendage (19) is engageable in the recess (20) in the manner of a press-stud.

7. A matching device (14) according to Claim 1, wherein the weight reducing cavities

(22) are of square cross-section.

8. A matching device (14) according to claim 1, wherein the profiled strips (15, 16)

are made of thermally insulating plastics material.

9. A matching device (14) according to Claim 8, characterized in that the thermally insulating plastics material is selected from elastomers constituted

by ethylene and propylene copolymers.

10. A matching device (14) according to any one of the preceding claims, whereby the two

profiled strips (15, 16) are of identical crosssection and arrangeable in opposed

positions, each profiled strip (15; 16) further comprising:

- a resiliently yielding lip (17a) which is in contact under pressure with a flat

portion (17b) of the other profiled strip (16; 15) when the door or window (2, 3)

is brought into a closed position;

- a resiliently yielding edging (18) which is in leaktight contact under pressure

with a transverse flange (13) of the other profiled strip (16; 15) when the door or

window (2, 3) is brought into a closed position, providing the matching device (14)

with four leaktight pressure contact points.

11. A profiled strip (15,16) for a matching device (14) for two profiled sections (8,

9) of a sliding door or window (2, 3) when they are in the closed position in a frame

(1), the profiled strip (15, 16) comprising a body (21) and being made of a thermally

insulating material, characterized in that the body (21) of the strips (8, 9) comprise a plurality of weight reducing cavities

(22) such that the cross-section of the profiled strips (15, 16) has a cross-walled

configuration achieving low thermal conductivity.

12. A profiled strip (15, 16) according to claim 11, made of thermally insulating plastics

material.

13. A profiled strip (15, 16) according to Claim 12, characterized in that the plastics material is selected from elastomers constituted by ethylene and propylene

copolymers.

14. Frame (6, 7) for sliding doors or windows (2, 3) comprising identical profiled sections

(8, 9) which meet when doors or windows (2, 3) are in a closed position and a matching

device (14) according to any one of claims 1 to 10.

15. Frame (6, 7) according to claim 14, wherein the profiled sections (8, 9) comprise

a box-like body (10) with two projecting flanges (11, 12) holding the panes of the

doors or windows (2, 3) and a transverse flange (13), the body (21) of each profiled

strip (15, 16) being housed between said box-like body (10) and said transverse flange

(13) of the respective profiled section (8, 9).

1. Passvorrichtung (14) für Profilabschnitte (8, 9) einer Schiebetür oder eines Schiebefensters

(2, 3), wenn sie sich in der geschlossenen Position in einem Rahmen (1) befinden,

wobei die Passvorrichtung (14) zwei Profilleisten (15, 16) umfasst, von denen jede

mit einem entsprechenden Profilabschnitt (8, 9) verbunden werden kann, und die Profilleisten

(15, 16) unter Druck in Kontakt miteinander sind, wenn die Tür bzw. das Fenster (2,

3) in eine geschlossene Position gebracht ist, und die Profilleisten (15, 16) einen

Körper (21) umfassen und aus einem wärmeisolierenden Material bestehen, dadurch gekennzeichnet, dass der Körper (21) der Leisten (8, 9) eine Vielzahl gewichtsverringemder Hohlräume (22)

umfasst, so dass der Querschnitt der Profilleisten (15, 16) eine Gitterwandstruktur

hat, die geringe Wärmeleitfähigkeit bewirkt.

2. Passvorrichtung (14) nach Anspruch 1, dadurch gekennzeichnet, dass die zwei Profilleisten (15, 16) identisch sind.

3. Passvorrichtung (14) nach Anspruch 1, dadurch gekennzeichnet, dass jede Profilleiste (15, 16) eine elastisch nachgebende Lippe (17a) umfasst, die in

der geschlossenen Position der Türen bzw. Fenster (2, 3) unter Druck in Kontakt mit

einem Abschnitt (17b) der anderen Profilleiste (16, 15) ist.

4. Passvorrichtung (14) nach Anspruch 3, dadurch gekennzeichnet, dass die Profilleiste (15, 16), die mit dem Profilabschnitt (8, 9) einer Tür bzw. eines

Fensters (2, 3) in Verbindung gebracht werden kann, eine elastisch nachgebende Kante

(18) umfasst, die in der geschlossenen Position der Türen bzw. Fenster (2, 3) unter

Druck in Kontakt mit dem Profilabschnitt (9, 8) des anderen Fensters bzw. der anderen

Tür (3, 2) ist.

5. Passvorrichtung (14) nach Anspruch 4, dadurch gekennzeichnet, dass jede Profilleiste (15, 16) einen Ansatz (19) umfasst, der mit einer Aussparung (20)

in Eingriff gebracht werden kann, die in dem jeweiligen Profilabschnitt (8, 9) ausgebildet

ist.

6. Passvorrichtung (14) nach Anspruch 5, dadurch gekennzeichnet, dass der Ansatz (19) wie ein Pressbolzen mit der Aussparung (20) in Eingriff gebracht

werden kann.

7. Passvorrichtung (14) nach Anspruch 1, wobei die gewichtsverringemden Hohlräume (22)

quadratischen Querschnitt haben.

8. Passvorrichtung (14) nach Anspruch 1, wobei die Profilleisten (15, 16) aus wärmeisolierendem

Kunststoffmaterial bestehen.

9. Passvorrichtung (14) nach Anspruch 8, dadurch gekennzeichnet, dass das wärmeisolierende Kunststoffmaterial aus Elastomeren ausgewählt wird, die durch

Ethylen- und Propylen-Copolymere gebildet werden.

10. Passvorrichtung (14) nach einem der vorangehenden Ansprüche, wobei die zwei Profilleisten

(15, 16) identischen Querschnitt haben und an einander gegenüberliegenden Positionen

angeordnet werden können, wobei jede Profilleiste (15; 16) des Weiteren umfasst:

eine elastisch nachgebende Lippe (17a), die unter Druck in Kontakt mit einem flachen

Abschnitt (17b) der anderen Profilleiste (16; 15) ist, wenn die Tür bzw. das Fenster

(2, 3) in eine geschlossene Position gebracht ist;

eine elastisch nachgebende Kante (18), die unter Druck in dichtem Kontakt mit einem

Querflansch (13) der anderen Profilleiste (16; 15) ist, wenn die Tür bzw. das Fenster

(2, 3) in eine geschlossene Position gebracht ist, und die die Passvorrichtung (14)

mit vier dichten Druckkontaktpunkten versieht.

11. Profilleiste (15, 16) für eine Passvorrichtung (14) für zwei Profilabschnitte (8,

9) einer Schiebetür oder eines Schiebefensters (2,3), wenn sie sich in der geschlossenen

Position in einem Rahmen (1) befinden, wobei die Profilleiste (15, 16) einen Körper

(21) umfasst und aus einem wärmeisolierenden Material besteht, dadurch gekennzeichnet, dass der Körper (21) der Leisten (8, 9) eine Vielzahl gewichtsverringernder Hohlräume

(22) umfasst, so dass der Querschnitt der Profilleisten (15, 16) eine Gitterwandstruktur

hat, die geringe Wärmeleitfähigkeit bewirkt.

12. Profilleiste (15, 16) nach Anspruch 11, die aus wärmeisolierendem Kunststoffmaterial

besteht.

13. Profilleiste (15, 16) nach Anspruch 12, dadurch gekennzeichnet, dass das Kunststoffmaterial aus Elastomeren ausgewählt wird, die durch Ethylen- und Propyten-Copolymere

gebildet werden.

14. Rahmen (6, 7) für Schiebetüren oder -fenster (2, 3), der identische Profilabschnitte

(8, 9), die aufeinander treffen, wenn sich die Türen bzw. Fenster (2, 3) in einer

geschlossenen Position befinden, und eine Passvorrichtung (14) nach einem der Ansprüche

1 bis 10 umfasst.

15. Rahmen (6, 7) nach Anspruch 14, wobei die Profilabschnitte (8, 9) einen kastenartigen

Körper (10) mit zwei vorstehenden Flanschen (11, 12), die die Scheiben der Türen bzw.

Fenster (2, 3) halten, und einem Querflansch (13) umfassen, wobei der Körper (21)

jeder Profilleiste (15, 16) zwischen dem kastenartigen Körper (10) und dem Querflansch

(13) des entsprechenden Profilabschnitts (8, 9) aufgenommen ist.

1. Dispositif coopérant (14) pour sections profilées (8, 9) d'une porte ou fenêtre coulissante

(2, 3) lorsqu'elles sont dans la position fermée dans un cadre (1), ledit dispositif

coopérant (14) comprenant deux bandes profilées (15, 16) chacune desquelles peut être

associée à une section profilée respective (8, 9), les bandes profilées (15, 16) étant

en contact mutuel sous pression lorsque la porte ou fenêtre (2, 3) est mise dans une

position fermée, les bandes profilées (15, 16) comprenant un corps (21) et étant faites

d'un matériau thermiquement isolant, caractérisé en ce que le corps (21) des bandes (8, 9) comprend une pluralité de cavités de réduction de

poids (22) telles que la section transversale des bandes profilées (15, 16) a une

configuration de parois croisées ayant une faible conductivité thermique.

2. Dispositif coopérant (14) selon la revendication 1, caractérisé en ce que les deux bandes profilées (15, 16) sont identiques.

3. Dispositif coopérant (14) selon la revendication 1, caractérisé en ce que chaque bande profilée (15, 16) comprend une lèvre cédante de façon résiliente (17a)

qui est, dans la position fermée des portes ou fenêtres (2, 3), en contact sous pression

avec une partie (17b) de l'autre bande profilée (16, 15).

4. Dispositif coopérant (14) selon la revendication 3, caractérisé en ce que la bande profilée (15, 16) pouvant être associée à la section profilée (8, 9) d'une

porte ou fenêtre (2, 3) comprend un bord cédant de façon résiliente (18) qui est,

dans la position fermée des portes ou fenêtres (2, 3), en contact sous pression avec

la section profilée (9, 8) de l'autre porte ou fenêtre (3, 2).

5. Dispositif coopérant (14) selon la revendication 4, caractérisé en ce que chaque bande profilée (15, 16) comprend un appendice (19) qui peut venir en prise

avec un retrait (20) formé dans la section profilée respective (8, 9).

6. Dispositif coopérant (14) selon la revendication 5, caractérisé en ce que l'appendice (19) peut venir en prise avec le retrait (20) de la manière d'un bouton

à pression.

7. Dispositif coopérant (14) selon la revendication 1, dans lequel les cavités de réduction

de poids (22) sont de section transversale carrée.

8. Dispositif coopérant (14) selon la revendication 1, dans lequel les bandes profilées

(15, 16) sont faites de matériau plastique thermiquement isolant.

9. Dispositif coopérant (14) selon la revendication 8, caractérisé en ce que le matériau plastique thermiquement isolant est sélectionné à partir d'élastomères

constitués par des copolymères d'éthylène et propylène.

10. Dispositif coopérant (14) selon l'une quelconque des revendications précédentes, dans

lequel les deux bandes profilées (15, 16) sont de section transversale identique et

peuvent être agencées dans des positions opposées, chaque bande profilée (15 ; 16)

comprenant en outre :

- une lèvre cédante de façon résiliente (17a) qui est en contact sous pression avec

une partie plate (17b) de l'autre bande profilée (16 ; 15) lorsque la porte ou fenêtre

(2, 3) est mise dans une position fermée ;

- une bordure cédante de façon résiliente (18) qui est en contact hermétique sous

pression avec une bride transversale (13) de l'autre bande profilée (16 ; 15) lorsque

la porte ou fenêtre (2, 3) est mise dans une position fermée, donnant au dispositif

coopérant (14) quatre points de contact de pression hermétiques.

11. Bande profilée (15, 16) pour un dispositif coopérant (14) pour deux sections profilées

(8, 9) d'une porte ou fenêtre coulissante (2, 3) lorsqu'elles sont dans la position

fermée dans un cadre (1), la bande profilée (15, 16) comprenant un corps (21) et étant

faite d'un matériau isolant thermiquement, caractérisé en ce que le corps (21) des bandes (8, 9) comprend une pluralité de cavités de réduction de

poids (22) telles que la section transversale des bandes profilées (15, 16) a une

configuration de parois croisées ayant une faible conductivité thermique.

12. Bande profilée (15, 16) selon la revendication 11, faite de matériau plastique isolant

thermiquement.

13. Bande profilée (15, 16) selon la revendication 12, caractérisée en ce que le matériau plastique est sélectionné à partir d'élastomères constitués par des copolymères

d'éthylène et propylène.

14. Cadre (6, 7) pour portes ou fenêtres coulissantes (2, 3) comprenant des sections profilées

identiques (8, 9) qui se rencontrent lorsque les portes ou fenêtres (2, 3) sont dans

une position fermée et un dispositif coopérant (14) selon l'une quelconque des revendications

1 à 10.

15. Cadre (6, 7) selon la revendication 14, dans lequel les sections profilées (8, 9)

comprennent un corps similaire à une boîte (10) avec deux brides en saillie (11, 12)

maintenant les vitres des portes ou fenêtres (2, 3) et une bride transversale (13),

le corps (21) de chaque bande profilée (15, 16) étant logé entre ledit corps similaire

à une boîte (10) et ladite bride transversale (13) de la section profilée respective

(8, 9).