| (19) |

|

|

(11) |

EP 1 810 946 B1 |

| (12) |

EUROPEAN PATENT SPECIFICATION |

| (45) |

Mention of the grant of the patent: |

|

19.08.2009 Bulletin 2009/34 |

| (22) |

Date of filing: 11.01.2007 |

|

| (51) |

International Patent Classification (IPC):

|

|

| (54) |

Bottle filling valve to be used in aseptic industrial bottling systems for juices,

beverages and in general for so-called still beverages

Flaschenfüllventil zur Verwendung in aseptischen industriellen Abfüllsystemen für

Säfte, Getränke und allgemein für sogenannte stille Getränke

Soupape de remplissage de bouteilles à utiliser dans des systèmes aseptiques d'embouteillage

industriel pour jus, boissons et en général pour les boissons dites plates

|

| (84) |

Designated Contracting States: |

|

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HU IE IS IT LI LT LU LV MC NL PL PT RO SE

SI SK TR |

| (30) |

Priority: |

18.01.2006 IT PD20060015

|

| (43) |

Date of publication of application: |

|

25.07.2007 Bulletin 2007/30 |

| (73) |

Proprietor: ACQUA MINERALE SAN BENEDETTO S.p.A. |

|

I-30037 Scorze' (Prov. of Venezia) (IT) |

|

| (72) |

Inventor: |

|

- Zoppas, Enrico

31015 Conegliano Veneto (TV) (IT)

|

| (74) |

Representative: Modiano, Micaela Nadia et al |

|

Dr. Modiano & Associati SpA

Via Meravigli 16

20123 Milano

20123 Milano (IT) |

| (56) |

References cited: :

EP-A1- 0 906 889

DE-B- 1 221 571

FR-A1- 2 842 799

US-A- 4 269 236

|

DE-A1- 3 325 338

FR-A1- 2 322 092

FR-A3- 2 721 305

|

|

| |

|

|

|

|

| |

|

| Note: Within nine months from the publication of the mention of the grant of the European

patent, any person may give notice to the European Patent Office of opposition to

the European patent

granted. Notice of opposition shall be filed in a written reasoned statement. It shall

not be deemed to

have been filed until the opposition fee has been paid. (Art. 99(1) European Patent

Convention).

|

[0001] The present invention relates to a bottle filling valve to be used in aseptic industrial

bottling systems for juices, beverages, and in general for so-called still beverages.

[0002] As is known, bottling systems for beverages intended for mass consumption must perform

bottling at extremely variable rates and must have a high productivity (typically

expressed as filled bottles per hour) in order to be able to achieve the necessary

economies of scale.

[0003] These systems are further required to have a certain production flexibility in order

to be able to bottle beverages having different flavors and bottle bottles having

different volumes.

[0004] Moreover, the particular and delicate environment in which bottling is performed,

which must be substantially aseptic in order to avoid the proliferation of germs and

bacteria inside the bottles once they have been bottled, forces bottling systems to

perform frequent sterilizing and sanitizing cycles.

[0005] The bottle filling step is performed by means of a certain number of filling valves;

these valves are generally the parts of the system that have a decisive role in the

filling rate.

[0006] In filling valves, it is important that germs and bacteria cannot enter the filling

duct, which generally ends with a sleeve which is inserted in the bottle.

[0007] In known valves, in particular in the case of valves of the mechanical type, this

often does not occur, since coaxial parts which compose the filling duct can move

with respect to each other in order to allow the opening of a flow control element

which closes said duct.

[0008] The interface between such mutually moving parts is a preferential path for the entry

of germs into the duct, in particular because the interface has a portion which is

exposed to the outside environment; during the relative movement of the parts, said

portion is carried inside the structure of the valve, facilitating the advancement

of the germs toward the duct.

[0009] Further, the structures of known valves are complicated and therefore have substantial

costs for their production and maintenance difficulties, and this is particularly

critical in view of the continuous bottling cycles.

[0010] DE 33 25 338 A1 discloses a bottle filling valve in accordance with the precharacterising portion

of the appended claim 1.

[0011] The aim of the present invention is to solve the problems noted in known types of

bottle filling valve.

[0012] Within this aim, an object of the present invention is to provide a bottle filling

valve to be used in aseptic industrial bottling systems for juices, beverages and

in general for so-called still beverages, which allows to maintain a high level of

asepsis during operation.

[0013] Another object of the present invention is to provide a bottle filling valve to be

used in aseptic industrial bottling systems for juices, beverages and in general for

so-called still beverages which allows a high filling rate.

[0014] Another object of the present invention is to provide a bottle filling valve to be

used in aseptic industrial bottling systems for juices, beverages and in general for

so-called still beverages which is structurally simple.

[0015] In accordance with the invention, there is provided a bottle filling valve as defined

in the appended claims.

[0016] Further characteristics and advantages of the invention will become better apparent

from the following detailed description of a preferred but not exclusive embodiment

thereof, illustrated by way of non-limiting example in the accompanying drawings,

therein:

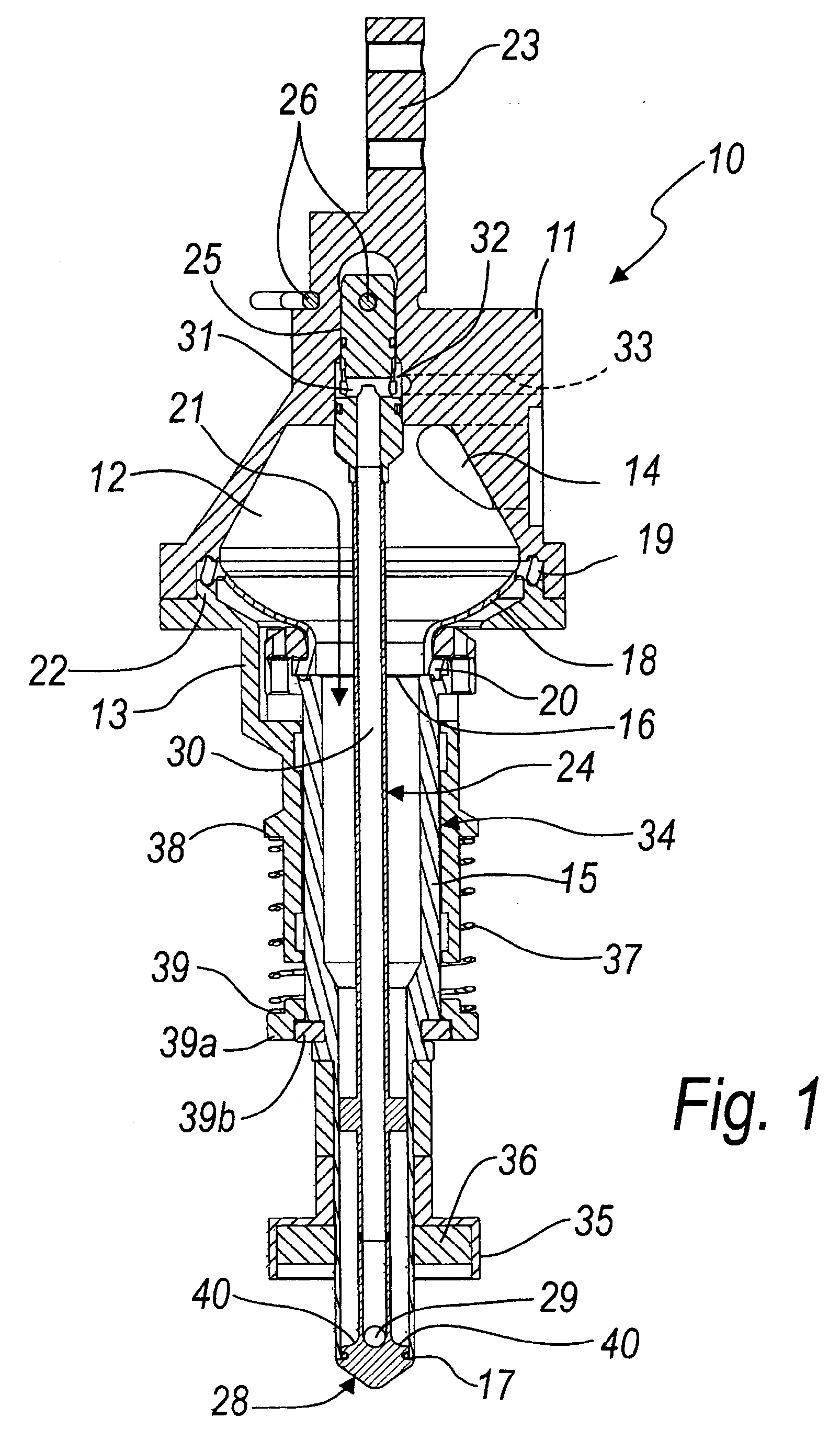

Figure 1 is a sectional view, taken along its main axis, of a bottle filling valve

according to the invention during closure;

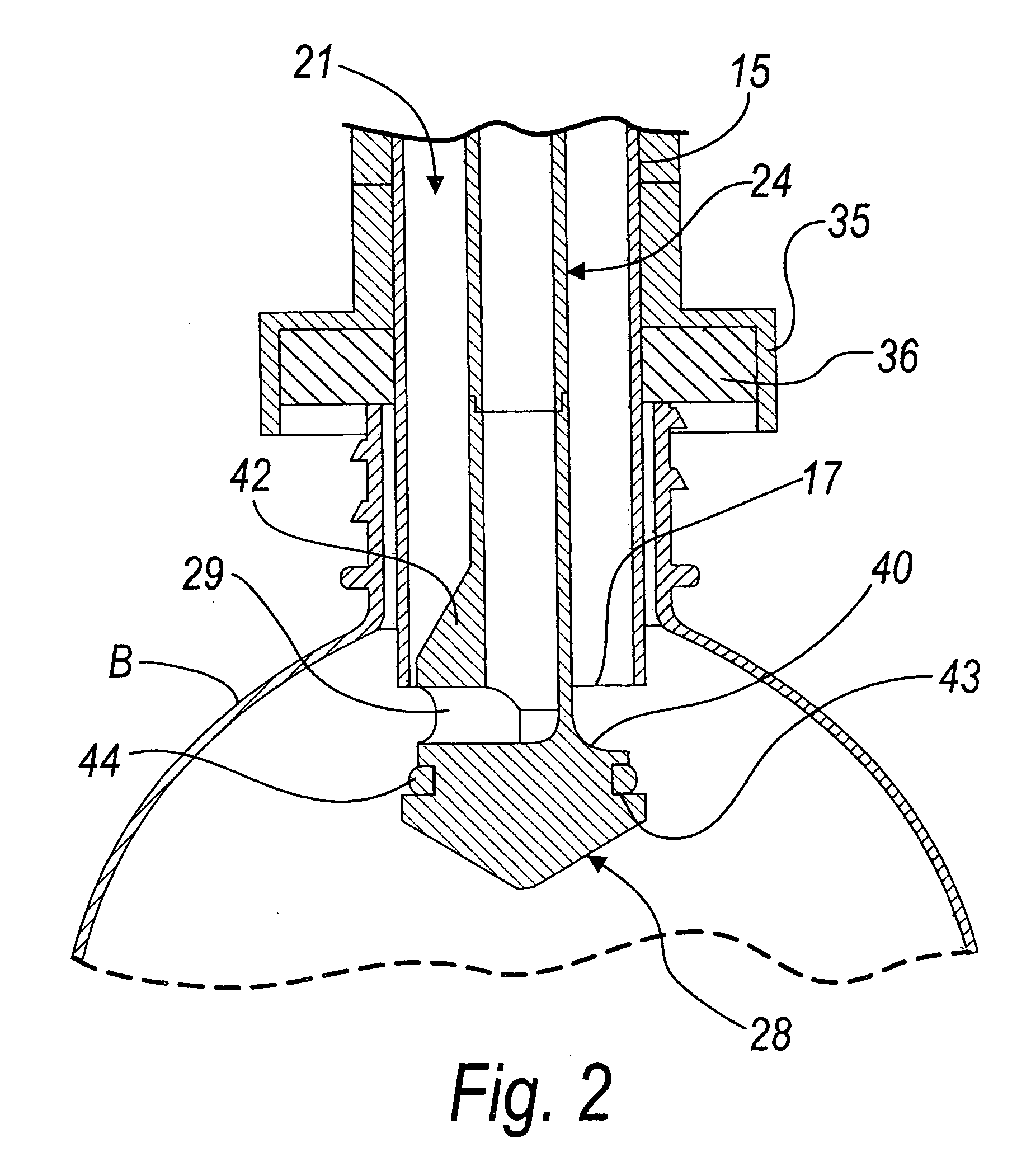

Figure 2 is a sectional view, taken along a plane which is perpendicular to the plane

of Figure 1, of a detail of the filling valve during opening-discharge.

[0017] It is noted that anything found to be already known during the patenting process

is understood not to be claimed and to be the subject of a disclaimer.

[0018] With reference to the figures, a bottle filling valve according to the invention

is generally designated by the reference numeral 10.

[0019] The valve 10 comprises an upper body 11, in which there is a chamber 12 which is

open downward, and a lower tubular body 13, which is fixed to the upper body 11 at

the lower rim of the chamber 12.

[0020] The chamber 12 is connected to a liquid supply system (not shown in the figures)

by means of an access hole 14.

[0021] Below the chamber 12, in a position which is partially internal and coaxial with

respect to the lower body 13, there is a sleeve 15 to be inserted in the bottle to

be filled (which is shown schematically and partially in Figure 2 and designated by

the reference letter B).

[0022] The sleeve 15 has, at its upper and lower ends, respectively an opening 16 for connection

to the chamber 12 and a port 17 for discharge into the bottle.

[0023] The chamber 12 and the sleeve 15 are mutually connected by means of a connecting

member which is formed by an annular membrane 18 made of plastic material, which is

elastic and impermeable and is fixed by its outer perimetric portion 19 to the lower

rim of the chamber 12 and by its inner perimetric portion 20 to the upper rim of the

sleeve 15.

[0024] The chamber 12, the wall of the annular membrane 18 and the sleeve 15 form the bottle

filling duct 21.

[0025] In particular, the outer perimetric portion 19 of the annular membrane 18 is locked

in a sandwich-like fashion between the lower rim of the chamber 12 and an annular

ridge 22 which is formed on the upper part of the lower body 13.

[0026] The upper body 11 has a part 23 for fixing to the structure for supporting and moving

the valve 10, which is not shown in the figures.

[0027] A tubular stem 24 is provided inside the filling duct 21, is fixed in an upper region

on the top of the chamber 12, and is coaxial to the sleeve 15.

[0028] The tubular stem 24 is locked by inserting the head 24a of the stem 24 in a seat

25 which is formed in the upper body 11 and the corresponding reversible locking in

the seat of the head 24a for its coupling with a fork-like pin 26, which is removable

and can be arranged outside the upper body 11.

[0029] The tubular stem 24 has, at its lower end, a flow control body 28 for the discharge

port 17 of the sleeve 15.

[0030] A vent hole 29 leads out laterally on the flow control body 28 and is connected to

the inside 30 of the tubular stem 24, which in turn is connected to an external system

for venting and/or recovering liquid, not shown in the figures.

[0031] In particular, the interior 30 of the tubular stem 24 ends on a transverse hole 31

formed in the head 24a of said stem, which in turn is open onto an annular slot 32

which is formed in the seat 25 and is isolated upward and downward by gaskets.

[0032] A connecting duct 33 is open on the annular slot 32 and connects it to said external

system for venting and/or recovering liquid.

[0033] The sleeve 15 comprises means 34 which are suitable to allow it to perform a relative

translational motion with respect to the tubular stem 24 from a position in which

the discharge port 17 is closed onto the flow control body 28 (Figure 1) to a position

in which the port 17 is raised from the flow control body 28 (Figure 2) when the sleeve

is inserted into the bottle to be filled.

[0034] The means 34, termed hereinafter "translational means 34", consist of the cylindrical

guide constituted by the internal surface of the lower body 13, which is substantially

tubular, and of an abutment ring 35, which is fixed coaxially to the portion of the

sleeve 15 that protrudes from the lower body 13 (the operation of which will be explained

hereinafter).

[0035] The abutment ring 35 is provided internally with an annular gasket 36 against which

the rim of the mouth of the bottle abuts.

[0036] Means for returning the discharge port 17 to the closure position on the flow control

body 28 are associated with the translational means 34 and are constituted by a spring

37, which is arranged coaxially to the lower body 13 and to the sleeve 15 between

a first annular abutment 38, formed on the lower body 13, and a second annular abutment

39, associated with the sleeve 15.

[0037] In particular, the second annular abutment 39 is constituted by an annular body 39a,

which is arranged in abutment against two half-rings 39b which are inserted in corresponding

annular slots formed on the outer surface of the sleeve 15.

[0038] The maximum relative translational motion between the sleeve 15 and the tubular stem

14 is equal to the distance between the lower body 13 and the annular abutment 39.

[0039] The flow control body 28 has, for a portion of its rotation about the axis of the

tubular stem 24, a portion 40 for blending with said tubular stem which tapers upward

so as to form a chute for conveyance toward the wall of the bottle for the liquid

that exits from the filling duct 21.

[0040] A rib 42 is provided on the angular blending portion between the flow control body

28 and the tubular stem 24 which is not tapered and has a radial extension equal to

the distance between the lateral surface of the tubular stem 24 and the internal surface

of the sleeve 15 (as clearly shown in Figure 2, in which the flow control body is

shown in cross-section with respect to a plane which is perpendicular to the sectional

plane of Figure 1).

[0041] The vent hole 29 is provided on the face of the rib 42 which is directed toward the

sleeve 15.

[0042] The rib 42, conveniently blended with the tubular stem 24, prevents the liquid being

discharged from blocking the vent hole 29.

[0043] The flow control body 28 has an annular shoulder 43, which is formed below the blending

portion 40 and against which the discharge port 17 of the sleeve 15 abuts for closure;

a gasket 44, for example of the O-Ring type, is provided at the annular shoulder 43.

[0044] Advantageously, guiding wings 45 protrude from mutually opposite portions of the

outer lateral surface of the tubular stem 24 and have a radial dimension which is

substantially equal to the distance between said outer lateral surface of the tubular

stem 24 and the inner surface of the sleeve 15.

[0045] The operation of the valve is as follows.

[0046] The upper body 11 is fixed to a supporting and movement structure, while the sleeve

15 abuts against the discharge port 17 on the flow control body 28 (which is rigidly

coupled to the upper body 11) by way of the thrust of the spring 37; the sleeve 15

is connected to the upper body 11 by the annular membrane 18.

[0047] A bottle B is moved below the valve 10; said valve is lowered, moving the sleeve

15 into the mouth of the bottle and arranging the abutment ring 35 on the rim of said

mouth of the bottle.

[0048] The descent of the valve continues for a certain extent, so that the rim of the mouth

of a bottle pushes against the abutment ring 35 by way of the contact with the gasket

36, with the consequence of producing the upward translational motion of the sleeve

15 with respect to the lower body 13 and therefore with respect to the upper body

11 with the tubular stem 24; accordingly, said sleeve rises from the flow control

body 28, thus opening the discharge port, with the consequent descent of liquid.

[0049] Opening occurs by virtue of the very weight of the valve 11 which, being supported

by the bottle B, overcomes the force of the spring 37.

[0050] The descent of the liquid continues until it reaches the vent hole 29.

[0051] At this point, dispensing is interrupted and the excess product flows out, through

the vent hole 29, from the liquid venting and/or recovery system, thus determining

the level inside the bottle.

[0052] Once filling has ended, the valve 10 is raised and the sleeve 15, by virtue of its

own weight and of the return spring, returns to the closure condition on the flow

control body.

[0053] In practice it has been found that the invention thus described solves the problems

noted in known types of filling valve; in particular, the present invention provides

a bottle filling valve to be used in aseptic industrial bottling systems for juices,

beverages and in general for so-called still beverages which allows to avoid entraining

gems and bacteria into the filling duct.

[0054] By way of the annular membrane which connects the chamber to the sleeve, a relative

movement of the two parts of the duct is obtained without however forming any interface

which might constitute a preferential path for the penetration of germs into the duct.

[0055] The structure of the valve is further extremely simple, facilitating its production

and maintenance.

[0056] The shape of the flow control body and the size of the interior 30 of the tubular

stem 24 further allow to optimize the flow of liquid that enters the bottle, with

a considerable increase in the filling rate with respect to known valves.

[0057] The invention thus conceived is susceptible of numerous modifications and variations,

all of which are within the scope of the appended claims; all the details may further

be replaced with other technically equivalent elements.

[0058] In practice, the materials employed, so long as they are compatible with the specific

use, as well as the dimensions, may be any according to requirements and to the state

of the art.

[0059] Where technical features mentioned in any claim are followed by reference signs,

those reference signs have been included for the sole purpose of increasing the intelligibility

of the claims and accordingly such reference signs do not have any limiting effect

on the interpretation of each element identified by way of example by such reference

signs.

1. A bottle filling valve to be used in aseptic industrial bottling systems for juices,

beverages and in general for so-called still beverages, comprising a filling duct

(21), which is substantially straight and is constituted, from the top downward, by

an upper body (11), in which there is a chamber (12) which is open downward and is

connected to a liquid supply system, and by a sleeve (15) to be inserted in a bottle

(B) to be filled, said sleeve (15) being in a position which is partially internal

and coaxial to a lower tubular body (13) fixed to said upper body (11), said sleeve

(15) having, at its upper and lower ends, respectively an opening (16) for connection

to said chamber (12) and a port (17) for discharge into the bottle, said chamber (12)

and said sleeve (15) being mutually connected by means of a connecting member formed

by an annular elastic and impermeable membrane (18), which is fixed by means of its

outer perimetric portion (19) to the lower rim of said chamber (12) and by means of

its inner perimetric portion (20) to the upper rim of said sleeve (15), a tubular

stem (24) being provided inside said filling duct (21) and being fixed in an upper

region on the top of said chamber (12) and having, at its lower end, a flow control

body (28) for said discharge port (17) of said sleeve (15), a vent hole (29) being

provided in said flow control body (28) and being connected to the inside of said

tubular stem (24), which in turn is connected to an external system for venting and/or

recovering liquid, said sleeve (15) comprising means (34) suitable to allow it to

perform a relative translational motion with respect to said tubular stem (24) from

a position in which the discharge port (17) is closed onto said flow control body

(28) to a position in which said discharge port (17) is raised from said flow control

body (28) when said sleeve (15) is inserted in the bottle to be filled, means for

the return to the closure position of said discharge port (17) on said flow control

body (28) being associated with said means for translational motion (34), the bottle

filling valve being characterized in that said lower tubular body (13) is fixed to said upper body (11) at the lower rim of

said chamber (12), below said chamber (12), said outer perimetric portion (19) of

said annular membrane (18) being locked in a sandwich-like fashion between the lower

rim of said chamber (12) and an annular ridge (22) which is provided on the upper

part of said lower body (13).

2. The bottle filling valve according to claim 1, characterized in that said tubular stem (24) is coaxial to said sleeve (15) and in that said flow control body (28) has, for a portion of its rotation about the axis of

said tubular stem (24), a portion (40) for blending with said tubular stem (24) which

tapers upward so as to form a chute for conveyance toward the wall of the bottle (B)

for the liquid that exits from said sleeve (15), a rib (42) being provided on the

angular blending portion between said flow control body (28) and said tubular stem

(24) which is not tapered, said rib having a radial extension whose dimensions are

equal to the distance between the lateral surface of said tubular stem (24) and the

internal surface of said sleeve (15), said vent hole (29) being provided on the face

of said rib (42) which is directed toward said sleeve (15).

3. The bottle filling valve according to one of the preceding claims, characterized in that said tubular stem (24) is locked by inserting the head (24a) of said tubular stem

(24) in a seat (25) provided in said upper body (11) and by reversible locking in

said seat by coupling to a fork-like pin (26) which can be extracted and can be arranged

outside said upper body (11).

4. The bottle filling valve according to one of the preceding claims, characterized in that the interior (30) of said tubular stem (24) ends on a transverse hole (31) provided

in said head (24a) of said tubular stem (24), which in turn is open onto an annular

slot (32) which is formed in said seat (25) and is insulated upward and downward by

gaskets, a connecting duct (33) being open on said annular slot (32) for connection

to said external system for venting and/or recovering liquid.

5. The bottle filling valve according to one of the preceding claims, characterized in that said means (34) suitable to allow it to perform a relative translational motion with

respect to said tubular stem (24) consist of the cylindrical guide formed by the internal

surface of said lower body (13) and of an abutment ring (35) which is flexed coaxially

to the portion of said sleeve (15) which protrudes from said lower body (13), said

abutment ring (35) being provided internally with an annular gasket (36) against which

the rim of the mouth of the bottle abuts.

6. The bottle filling valve according to one of the preceding claims, characterized in that said means for returning to the closure position said discharge port (17) on the

flow control body (28) are constituted by a spring (37), which is arranged coaxially

to said lower body (13) and to said sleeve (15) between a first annular abutment (38),

provided on said lower body (13) and a second annular abutment (39), which is associated

with said sleeve (15).

7. The bottle filling valve according to claim 6, characterized in that said second annular abutment (39) is constituted by an annular body (39a) which is

arranged in abutment on two half-rings (39b), which are inserted in corresponding

annular slots provided on the outer surface of said sleeve (15).

8. The bottle filling valve according to claim 2, characterized in that said rib (42) is blended with said tubular stem (24).

9. The bottle filling valve according to one of the preceding claims, characterized in that guiding wings (45) protrude from mutually opposite portions of the outer lateral

surface of said tubular stem (24) and have, in a radial direction, dimensions which

are substantially equal to the distance between said outer lateral surface of said

tubular stem (24) and the internal surface of said sleeve (15).

10. The bottle filling valve according to claim 2, characterized in that said flow control body (28) has an annular shoulder (43), which is formed below said

blending portion (40), against which said discharge port (17) of the sleeve (15) abuts

for closure, a gasket (44) being provided at said annular shoulder (43).

1. Flaschenfüllventil zur Verwendung in aseptischen industriellen Flaschenfüllsystemen

für Säfte, Getränke und allgemein für sogenannte stille Getränke, mit einem Füllkanal

(21), der im Wesentlichen gerade und, von oben nach unten, aus einem oberen Gehäuse

(11), in dem eine Kammer (12) ist, die nach unten offen und mit einem Flüssigkeitszufuhrsystem

verbunden ist, und aus einer Hülse (15), die in eine zu befüllende Flasche (B) einzuführen

ist, gebildet ist, wobei die Hülse (15) in einer Lage ist, die teilweise innerhalb

und koaxial zu einem unteren rohrförmigen Gehäuse (13) ist, das an dem oberen Gehäuse

(11) befestigt ist, wobei die Hülse (15) eine Öffnung (16) zum Anschluss an die Kammer

(12) und eine Öffnung (17) für den Ausstoß in die Flasche an ihrem oberen bzw. unteren

Ende hat, wobei die Kammer (12) und die Hülse (15) mittels eines Verbindungsteiles

miteinander verbunden sind, das aus einer ringförmigen elastischen und undurchlässigen

Membran (18) besteht, die mittels ihres äußeren Umfangsteiles (19) an dem unteren

Rand der Kammer (12) und mittels ihres inneren Umfangsteiles (20) an dem oberen Rand

der Hülse (15) befestigt ist, wobei ein rohrförmiger Stab (24) in dem Kanal (21) vorgesehen

und in einem oberen Bereich an dem oberen Ende der Kammer (12) befestigt ist und an

seinem unteren Ende einen Strömungssteuerungskörper (28) für die Ausstoßöffnung (17)

der Hülse (15) hat, wobei ein Entlüftungsloch (29) in dem Strömungssteuerungskörper

(28) vorgesehen und mit der Innenseite des rohrförmigen Stabes (24) verbunden ist,

der wiederum mit einem externen System zum Entlüften und/oder Wiedergewinnen von Flüssigkeit

verbunden ist, wobei die Hülse (15) Mittel (34) aufweist, die geeignet sind, um ihr

zu gestatten, eine relative Translationsbewegung bezüglich des rohrförmigen Stabes

(24) aus einer Stellung, in der die Ausstoßöffnung (17) durch den Strömungssteuerungskörper

(28) geschlossen ist, in eine Stellung, in der die Ausstoßöffnung - (17) von dem Strömungssteuerungskörper

(28) abgehoben ist, wenn die Hülse (15) in eine zu befüllende Flasche eingeführt ist,

durchzuführen, wobei Mittel für die Rückkehr in die Schließstellung der Ausstoßöffnung

(17) an dem Strömungssteuerungskörper (28) mit den Mitteln für eine Translationsbewegung

(34) verbunden sind, wobei das Flaschenfüllventil dadurch gekennzeichnet ist, dass das untere rohrförmige Gehäuse (13) an dem oberen Gehäuse (11) an dem unteren Rand

der Kammer (12) unter der Kammer (12) befestigt ist, wobei der äußere Umfangsteil

(19) der ringförmigen Membran (18) sandwichartig zwischen dem unteren Rand der Kammer

(12) und einem ringförmigen Wulst (22), der an dem oberen Teil des unteren Gehäuses

(13) vorgesehen ist, festgehalten ist.

2. Flaschenfüllventil nach Anspruch 1, dadurch gekennzeichnet, dass der rohrförmige Stab (24) koaxial zu der Hülse (15) ist, und dass der Strömungssteuerungskörper

(28) über einen Teil seiner Drehung um die Achse des rohrförmigen Stabes (24) einen

Teil (40) zum Ineinandergehen mit dem rohrförmigen Stab (24) hat, der sich nach oben

verjüngt, um eine Rutsche zum Fördern der aus der Hülse (15) austretenden Flüssigkeit

in Richtung auf die Wand der Flasche (B) zu bilden, wobei eine Rippe (42) an dem winkelförmigen

Übergangsteil zwischen dem Strömungssteuerungskörper (28) und dem rohrförmigen Stab

(24), der nicht verjüngt ist, vorgesehen ist, wobei die Rippe eine radiale Ausdehnung

hat, deren Abmessungen gleich dem Abstand zwischen der seitlichen Fläche des rohrförmigen

Stabes (24) und der inneren Fläche der Hülse (15) ist, wobei das Entlüftungsloch (29)

auf der Außenseite der Rippe (42) vorgesehen ist, die auf die Hülse (15) gerichtet

ist.

3. Flaschenfüllventil nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der rohrförmige Stab (24) durch Einführen des Kopfes (24a) des rohrförmigen Stabes

(24) in einen in dem oberen Gehäuse (11) vorgesehenen Sitz (25) und durch umkehrbares

Festhalten in dem Sitz durch Verbinden mit einem gabelähnlichen Stift (26), der herausgezogen

und außerhalb des oberen Gehäuses (11) angeordnet werden kann, festgehalten wird.

4. Flaschenfüllventil nach einem der vorhergehenden Ansprüche, dass die Innenseite (30)

des rohrförmigen Stabes (24) an einem in dem Kopf (24a) des rohrförmigen Stabes (24)

vorgesehenen querverlaufenden Loch (31) endet, das wiederum zu einem ringförmigen

Schlitz (32) hin offen ist, der in dem Sitz (25) gebildet und nach oben und nach unten

durch Dichtungen isoliert ist, wobei ein Verbindungskanal (33) zu dem ringförmigen

Schlitz (32) zum Anschluss an das externe System zum Entlüften und/oder Wiedergewinnen

von Flüssigkeit offen ist.

5. Flaschenfüllventil nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Mittel (34), die geeignet sind, um ihr zu gestatten, eine relative Translationsbewegung

bezüglich des rohrförmigen Stabes (24) durchzuführen, aus der zylindrischen Führung,

die von der inneren Oberfläche des unteren Gehäuses (13) gebildet wird und aus einem

Widerlagerring (35) bestehen, der koaxial zu dem Abschnitt der Hülse (15) befestigt

ist, der von dem unteren Gehäuse (13) vorsteht, wobei der Widerlagerring (35) innen

mit einer ringförmigen Dichtung (36) versehen ist, an die der Rand der Öffnung der

Flasche anstößt.

6. Flaschenfüllventil nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass die Mittel zum Zurückführen der Ausstoßöffnung (17) in die Schließstellung an dem

Strömungssteuerkörper (28) aus einer Feder (37) bestehen, die koaxial zu dem unteren

Gehäuse (13) und der Hülse (15) zwischen einem ersten ringförmigen Widerlager (38),

das an dem unteren Gehäuse (13) vorgesehen ist, und einem zweiten ringförmigen Widerlager

(39), das mit der Hülse (15) verbunden ist, angeordnet ist.

7. Flaschenfüllventil nach Anspruch 6, dadurch gekennzeichnet, dass das zweite ringförmige Widerlager (39) von einem ringförmigen Körper (39a) gebildet

wird, der in Anlage an zwei Halbringen (39b) angeordnet ist, die in entsprechende

ringförmige Schlitze eingesetzt sind, die an der äußeren Oberfläche der Hülse (15)

vorgesehen sind.

8. Flaschenfüllventil nach Anspruch 2, dadurch gekennzeichnet, dass die Rippe (42) in den rohrförmigen Stab (24) übergeht.

9. Flaschenfüllventil nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass Führungsflügel (45) von einander entgegengesetzten Abschnitten der äußeren seitlichen

Fläche des rohrförmigen Stabes (24) abstehen und in einer Radialrichtung Abmessungen

haben, die im Wesentlichen gleich dem Abstand zwischen der äußeren seitlichen Oberfläche

des rohrförmigen Stabes (24) und der inneren Oberfläche der Hülse (15) sind.

10. Flaschenfüllventil nach Anspruch 2, dadurch gekennzeichnet, dass der Strömungssteuerungskörper (28) einen ringförmigen Absatz (43) hat, der unter

dem Übergangsteil (40) gebildet ist, an dem die Ausstoßöffnung (17) der Hülse (15)

zum Schließen anstößt, wobei eine Dichtung (44) an dem ringförmigen Absatz (43) vorgesehen

ist.

1. Valve de remplissage de bouteille destinée à être utilisée dans des systèmes de mise

en bouteille industrielle pour des jus, boissons et en général boissons non gazeuses,

comportant un conduit (21) de remplissage, qui est sensiblement droit et est constitué,

à partir de l'extrémité inférieure, par un corps supérieur (11), dans lequel est prévue

une chambre (12) ouverte vers le bas et est reliée à un système d'alimentation de

liquide, et par un manchon (15) destiné à être inséré dans une bouteille (B) destinée

à être remplie, ledit manchon (15) étant dans une position qui est partiellement interne

et coaxiale à un corps tubulaire inférieur (13) fixé audit corps (11) supérieur, ledit

manchon (15) ayant, à ses extrémités supérieure et inférieure, respectivement une

ouverture (16) pour liaison à ladite chambre (12) et un port (17) pour décharge dans

la bouteille, ladite chambre (12) et ledit manchon étant mutuellement liés au moyen

d'un élément de connexion formé par une membrane (18) imperméable, élastique et annulaire,

qui est fixée au moyen de sa partie de périmètre extérieur (19), à la périphérie inférieure

de ladite chambre (12), et au moyen de sa partie de périmètre (20) intérieure au périmètre

extérieur dudit manchon (15), une tige tubulaire (24) étant prévue à l'intérieur dudit

conduit de remplissage (21) et étant fixée dans une partie supérieure du sommet de

ladite chambre (12) et ayant à son extrémité inférieure un corps (28) de commande

d'écoulement pour ledit port d'évacuation (17) dudit manchon (15), un trou d'évacuation

(29) étant prévu dans ledit corps (28) de commande d'écoulement et étant relié à l'intérieur

de ladite tige (24) tubulaire, qui à son tour est reliée à un système externe pour

évacuer et/ou récupérer du liquide, ledit manchon (15) comprenant des moyens (34)

aptes à permettre à ce dernier de réaliser un mouvement relatif de translation par

rapport à ladite tige tubulaire (24), à partir d'une position dans laquelle le port

(17) d'évacuation est fermé sur ledit corps (28) de commande d'écoulement en une position

dans laquelle ledit port (17) d'évacuation est relevé par rapport audit corps (28)

de commande d'écoulement lorsque ledit manchon (15) est inséré dans la bouteille destinée

à être remplie, des moyens pour le retour en position fermée dudit port d'évacuation

(17) sur ledit corps de commande d'évacuation (28), étant associés auxdits moyens

pour ledit mouvement de translation (34), la valve étant caractérisée en ce que ledit cops (13) tubulaire inférieur est fixé audit corps supérieur (11) en la périphérie

inférieure de ladite chambre (12), sous ladite chambre (12), ladite partie (19) de

périmètre extérieure de ladite membrane (18) annulaire étant bloquée en sandwich entre

la périphérie inférieure de ladite chambre (12) et une arête (22) annulaire qui est

prévue sur la partie supérieure dudit corps inférieur (13).

2. Valve de remplissage de bouteille selon la revendication 1, caractérisée en ce que ladite tige tubulaire (24) et coaxiale audit manchon (15) et en ce que ledit corps (28) de commande d'écoulement présente, pour une partie de sa rotation

autour de l'axe de ladite tige (24) tubulaire, une partie (40) confondue avec ladite

tige (24) tubulaire qui s'amincit vers le haut afin de former une chute pour évacuation

vers la paroi de la bouteille (B) pour le liquide qui sort dudit manchon (15), une

nervure (42) étant prévue sur la partie confondue angulaire entre ledit corps de commande

d'écoulement (28) et ladite tige tubulaire (24) qui n'est pas amincie, ladite nervure

ayant une extension radiale dont les dimensions sont égales à la distance entre la

surface latérale de ladite tige tubulaire (24) et la surface interne dudit manchon

(15), ledit trou d'évacuation (29) étant prévu sur la face de ladite nervure (42)

qui est dirigée vers ledit manchon (15).

3. Valve selon l'une des revendications précédentes, caractérisée en ce que ladite tige (24) tubulaire est bloquée par l'insertion de la tête (24a) de ladite

tige (24) tubulaire dans un siège (25) prévu sur ledit corps supérieur (11) par un

mécanisme de blocage réversible dans ledit siège par couplage à une aiguille (26)

en fourche qui peut être extraite et peut être disposée à l'extérieur dudit corps

(11) supérieur.

4. Valve selon l'une des revendications précédentes, caractérisée en ce que l'intérieur (30) de ladite tige (24) tubulaire se termine sur un trou transversal

(31) prévu dans ladite tête (24a) de ladite tige tubulaire (24), qui à son tour est

ouverte sur une fente annulaire (32) formée dans ledit siège (25) et est isolée vers

le haut et vers le bas par des joints annulaires, un conduit de liaison (33) étant

ouvert sur ladite fente (32) annulaire pour liaison vers ledit système externe pour

l'évacuation et/ou la récupération de liquide.

5. Valve selon l'une des revendications précédentes, caractérisée en ce que lesdits moyens (34), aptes à permettre son déplacement de translation relatif par

rapport à ladite tige (24) tubulaire, consistent en le guide cylindrique formé par

la surface interne dudit corps (13) inférieur et un anneau (35) de butée qui est fixé

coaxialament à la partie dudit manchon (15) qui fait saillie par rapport audit corps

inférieur (13), ledit anneau (35) de butée étant réalisé de façon interne avec un

joint annulaire (36) contre lequel la périphérie du goulot de la bouteille vient en

butée.

6. Valve selon l'une des revendications précédentes, caractérisée en ce que lesdits moyens pour retourner en position de fermeture ledit port (17) d'évacuation

sur le corps (28) de commande d'écoulement sont constitués par un ressort (37) qui

est disposé coaxialement audit corps (13) inférieur et audit manchon (15), entre une

première butée (38) annulaire prévue sur ledit corps inférieur (13) et une seconde

butée (39) qui est associée audit manchon (15).

7. Valve selon la revendication 6, caractérisée en ce que ladite seconde butée annulaire (39) est constituée par un corps (39a) annulaire qui

est disposé en butée sur deux demi anneaux (39b) qui sont insérés dans des fentes

annulaires correspondantes prévues sur la surface extérieure dudit manchon (15).

8. Valve selon la revendication 2, caractérisée en ce que ladite nervure (42) se fond avec ladite tige tubulaire (24).

9. Valve selon l'une des revendications précédentes, caractérisée en ce que des ailes de guidage (45) font saillie à partir des parties opposées mutuellement

de la surface interne extérieure de ladite tige (24) tubulaire et présentent dans

une direction radiale des dimensions qui sont sensiblement égales à la distance entre

ladite surface latérale extérieure de ladite tige (24) tubulaire, et la surface interne

dudit manchon (15).

10. Valve selon la revendication 2, caractérisée en ce que le corps (28) de commande d'écoulement présente un épaulement (43) annulaire qui

est formé sous ladite partie (40) confondue contre laquelle ledit port d'évacuation

(17) du manchon (15) est en butée pour fermeture, un joint annulaire (44) étant prévu

sur ledit épaulement annulaire (43).

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the reader's convenience only.

It does not form part of the European patent document. Even though great care has

been taken in compiling the references, errors or omissions cannot be excluded and

the EPO disclaims all liability in this regard.

Patent documents cited in the description