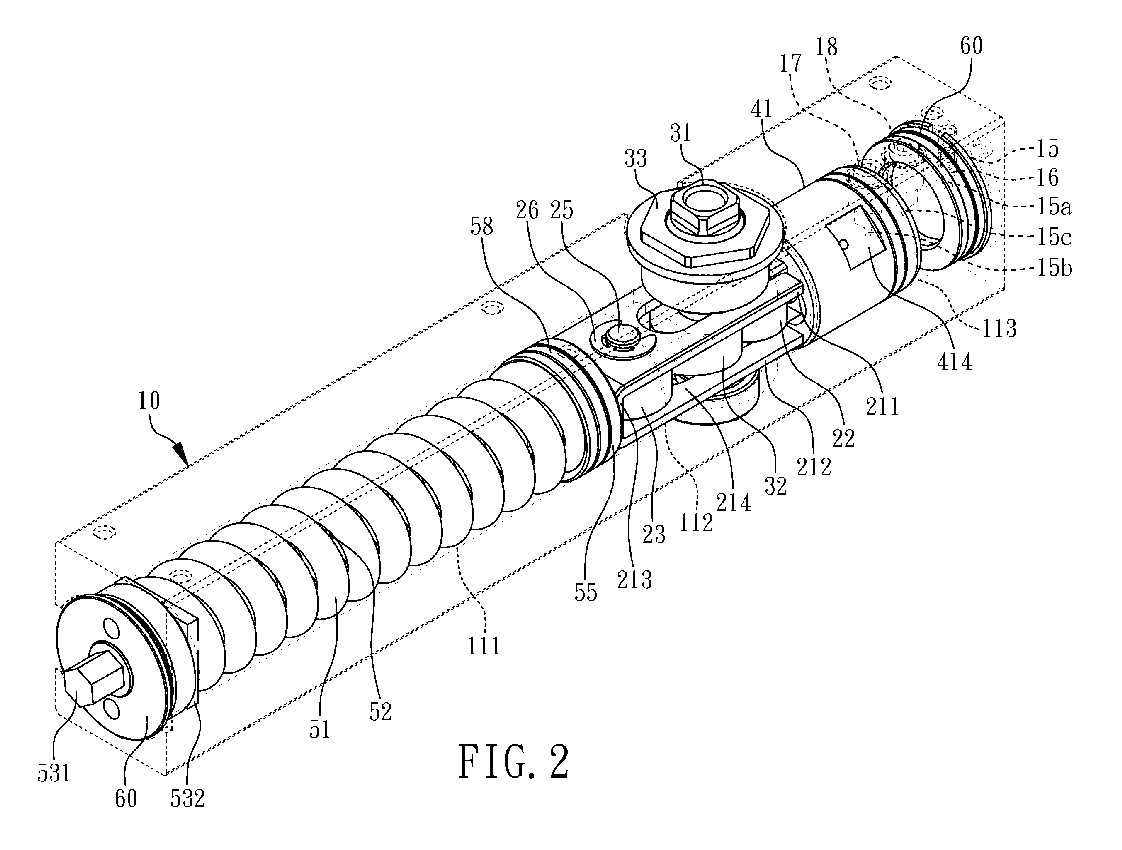

(57) An automatic door closer comprises a casting 10, a sliding assembly 20, a drive assembly

30, a tube shaped piston 41 and a first resilient member 51. The casting 10 has a

front chamber 111, a rear chamber 113, a middle chamber 112 in communication with

the front chamber 111 and the rear chamber 113, a shaft hole 12 penetrating the middle

chamber 112 and a first oil passage 13. The first oil passage 13 has an oil inlet

13a in communication with the front chamber 111 and an oil outlet 13b in communication

with the rear chamber 113. The sliding assembly 20 disposed within the middle chamber

112 of the casting 10 comprises a slider 21 disposed between the oil inlet 13a and

the oil outlet 13b, a first roller 22 and a second roller 23, wherein the first and

second rollers 22, 23 arc disposed within the slider 21 respectively. The drive assembly

30 comprises a shaft 31 and an eccentric cam 32 coupled to the shaft 31, the shaft

31 is pivotally disposed within the shaft hole 12 of the casting 10, the eccentric

cam 32 is located within the slider 21 and contacts against the first and second rollers

22, 23 of the sliding assembly 20. The tube shaped piston 41 disposed within the rear

chamber 113 of the casting 10 has a first end portion 411 and a second end portion

412 opposite to the first end portion 411, the first end portion 411 is connected

with the first roller 22. The first resilient member 51 is disposed within the front

chamber 111 of the casting 10 serving for pushing the slider 21 of the sliding assembly

20 to move.

|

|