| (19) |

|

|

(11) |

EP 1 873 873 B1 |

| (12) |

EUROPEAN PATENT SPECIFICATION |

| (45) |

Mention of the grant of the patent: |

|

11.04.2012 Bulletin 2012/15 |

| (22) |

Date of filing: 29.06.2007 |

|

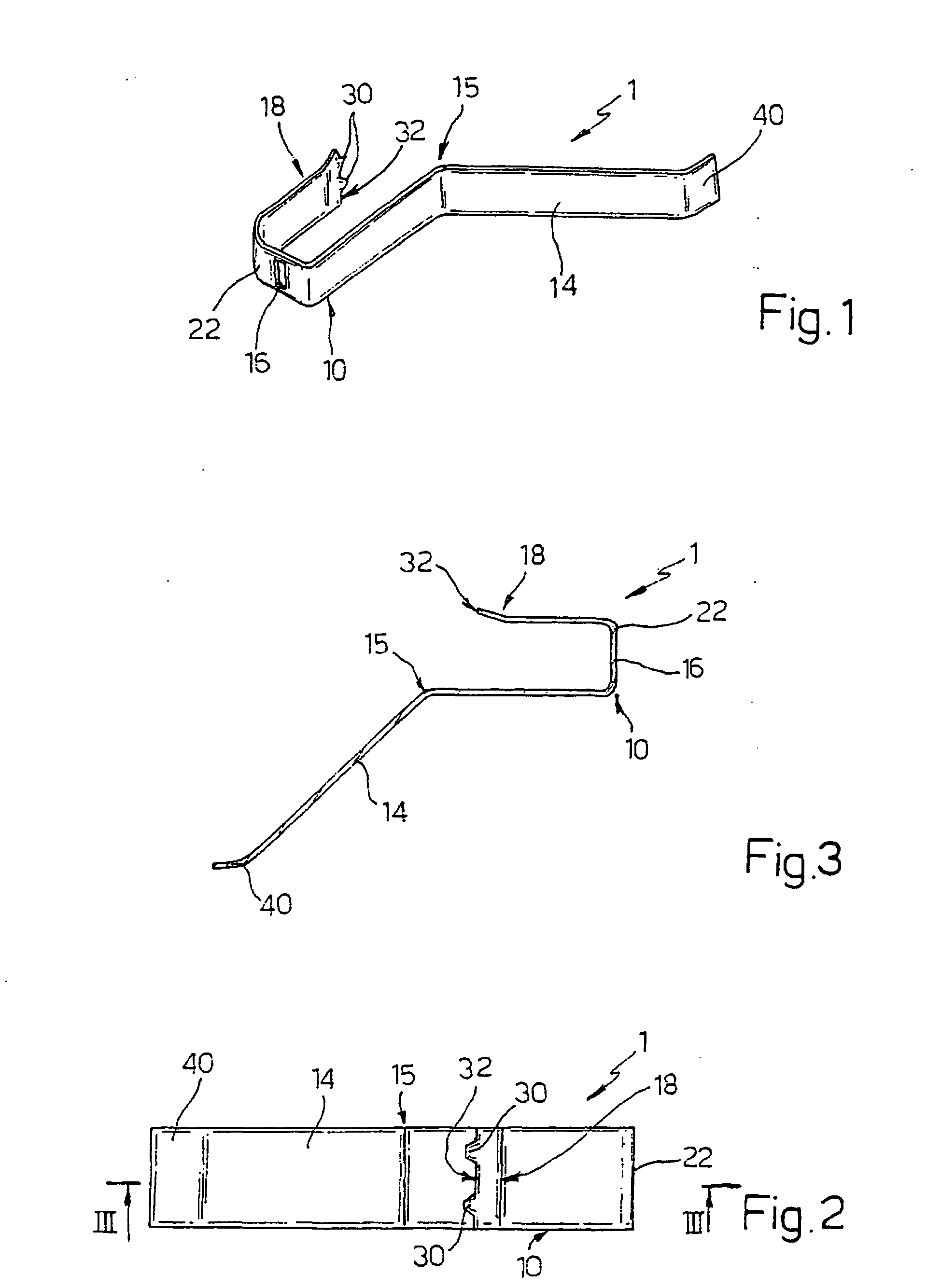

| (51) |

International Patent Classification (IPC):

|

|

| (54) |

Fast-fit electric connecting device and use thereof for neutralizing a surplus high-voltage

output terminal of an electronic gas lighter for electric household appliances, in

particular a cooking range

Elektrische Anschlussvorrichtung mit schneller Montage und deren Verwendung zur Neutralisierung

einer überschüssigen Hochspannungsausgangsklemme eines elektronischen Gasanzünders

für elektrische Haushaltsgeräte, im Besonderen eines Küchenherdes

Dispositif de connexion électrique rapide et son utilisation pour neutraliser un excès

de terminal de sortie de haute tension d'un allumoir à gaz électronique pour appareils

électroménagers, en particulier une plaque de cuisson

|

| (84) |

Designated Contracting States: |

|

ES IT PL TR |

| (30) |

Priority: |

30.06.2006 IT TO20060484

|

| (43) |

Date of publication of application: |

|

02.01.2008 Bulletin 2008/01 |

| (73) |

Proprietor: ITW Industrial Components S.r.l.

con Unico Socio |

|

20122 Milano (IT) |

|

| (72) |

Inventors: |

|

- Pianezze, Daniele

21012, Cassano Magnago (IT)

- Saligari, Umberto

21040, Vedano Olona (IT)

|

| (74) |

Representative: Jorio, Paolo et al |

|

Studio Torta S.p.A.

Via Viotti, 9

10121 Torino

10121 Torino (IT) |

| (56) |

References cited: :

EP-A- 1 101 066

WO-A-00/07263

|

EP-A- 1 469 255

WO-A-84/03180

|

|

| |

|

|

|

|

| |

|

| Note: Within nine months from the publication of the mention of the grant of the European

patent, any person may give notice to the European Patent Office of opposition to

the European patent

granted. Notice of opposition shall be filed in a written reasoned statement. It shall

not be deemed to

have been filed until the opposition fee has been paid. (Art. 99(1) European Patent

Convention).

|

[0001] The present invention relates to a fast-fit electric connecting device intended to

be coupled to a terminal, in particular a high-voltage output terminal, of an electronic

gas lighter device for an electric household appliance; and to the use thereof for

neutralizing a surplus high-voltage output terminal exceeding the number of terminals

needed by the aforesaid gas lighter device by electrically grounding the surplus terminal,

in particular for electrically connecting the surplus terminal to an electric conducting

element of the electric household appliance, typically a cooking range, against which

the gas lighter device is intended to be integrally fastened in use, by means of screws

and/or by snap-fitting.

[0002] It is known that the lighting of gas fed cooking ranges for electric household appliances

is performed by means of electronic gas lighter devices, which are mounted in close

contact against the lower face of the cooking range, forming an electrically conducting

element normally electrically connected (e.g. by means of the terminal board of the

gas lighter device itself) to a reference potential (so-called "grounding connection"),

for safety reasons.

[0003] From

European patent n. 1101066B1 it is known to rapidly and electrically ground part of the lighting circuit of the

gas lighter device (in order to avoid electromagnetic interference) by means of a

U-shaped grounding spring which is integrally carried by the gas lighter device, astride

an edge of the electrically insulating casing of the gas lighter device itself, in

order to be sandwiched (squeezed) in use between such a casing and the electrically

conductive element of the cooking range, so that the circuit of the gas lighter device

is automatically grounded through the latter by means of the simple fixing of the

gas lighter device to the cooking range, generally obtained by snap-fitting, by means

of specific teeth of the casing which engage perforated seats of the cooking range,

and/or by means of screws.

[0004] Furthermore, from

European patent application n. EP 1469255A1 it is known that the gas lighter devices available on the market today all display

an even number of output terminals; each terminal is intended in use to supply high

voltage to a spark plug of a burner of a cooking range. Therefore, in the case of

a cooking range having an odd number of burners, a gas lighter device having an immediately

following even number of terminals must be used and the surplus terminal must be grounded,

by means of a specific wire, so as to neutralize the action thereof without damaging

the operation of the lighter.

[0005] A drawback of the above-described solution therefore consists in that the assembler

of the cooking range must use an additional grounding wire (as well as the grounding

wire prescribed by the specifications for the device as a whole, possibly replaced

by the U-spring according to

EP 1101066B1), with consequent increased costs, times and assembly difficulties (the operation

is normally performed in restricted spaces).

[0006] It is the object of the present invention to solve the drawbacks of the above-described

known devices of the prior art, by providing a fast-fit device for the electric connection

of a high-voltage output terminal of an electronic gas lighter device to an electric

conducting element of an electric household appliance, against which the gas lighter

device is intended to be integrally fixed in use, e.g. a cooking range, which is both

highly reliable, of low manufacturing and assembly cost and small in size, and which

essentially allows to completely avoid the use of grounding wires, without however

requiring modifications to the internal structure of the gas lighter device, such

as required instead by the solution to the same technical problem known from

EP 1469255A1.

[0007] The present invention thus relates to a device of the aforesaid type, as defined

in claim 1.

[0008] In particular, the device according to the invention is used, according to an aspect

of the invention, to neutralize, by means of grounding through the electric connection

to the mentioned electric conducting element of the electric household appliance,

of a high-voltage output terminal of the gas lighter device exceeding the number of

high-voltage output terminals needed by the electric household appliance itself.

[0009] The device according to the invention consists in an elastically deformable metallic

foil, comprising: a U-shaped assembly portion, adapted to be inserted in a contact

carrier stack of an electrically non-conducting casing of the gas lighter device;

and a working portion defined by an arm, which extends askew and cantilevered from

a first end of the assembly portion and which is shaped so as to be adapted, in use,

to extend in cantilevered manner out of the contact carrier stack and distanced from

the casing to cooperate in contact against the electrically conducting element.

[0010] The assembly portion is then provided with a slot for the mechanical and electrical

coupling with a respective blade contact (to be neutralized) accommodated within the

contact carrier stack of the casing of the gas lighter device and with a second end,

opposite to the first, and adapted to engage in use an internal side wall of the contact

carrier stack, consequent to an elastic deformation of the foil consequent to the

reciprocal contact between the cantilevered arm of the working portion and the electrically

conducting element of the electric household appliance.

[0011] In this manner, it is possible to arrange the contact device formed of the foil onto

the high-voltage terminal to be neutralized (e.g. the sixth terminal of a gas lighter

device intended to equip a cooking range having only five burners) simply by inserting

the assembly portion in the respective contact carrier stack corresponding to the

terminal to be neutralized, which is engaged in the slot of the foil, thus leaving

the arm askew and laterally cantilevered, transversally with respect to a longitudinal

axis of the gas lighter device, out of the stack and so as to be distanced in a cantilevered

manner from the casing of the gas lighter device, askew with respect to the aforesaid

axis of symmetry of the gas lighter device and towards the conducting element formed

by the cooking range.

[0012] Thus, as a consequence of the assembly of the gas lighter device on the cooking range,

performed for example by snapping or by means of screws as shown in

EP 1101066B1, the aforesaid arm extends askew and cantilevered from the stack of the terminal

to be neutralized with respect to the casing, and in direction so as to be distanced

from the casing itself, is pressed against the cooking range with at least its free

end by interference coupling, because it protrudes from the casing of the gas lighter

device towards the cooking range more than the clearance normally present in use,

after assembly, between casing of the gas lighter device and surface of the cooking

range of other conducting element of the electric household appliance to which the

gas lighter device is fixed in use (e.g. to the part of the armature of the household

appliance).

[0013] Therefore, the askew and cantilevered arm of the working portion of the connection

device according to the invention elastically bends, thus leading the coupling portion

of the stack to possibly turn (in the presence of sufficient clearance), on the terminal

to be neutralized (which serves as a hinge), taking the end of the assembly portion

opposite to the cantilevered arm and provided with specific teeth, to be driven into

the relatively soft synthetic plastic material, forming the side wall of the stack,

thus ensuring the impossibility of accidental removal of the foil of the fast-fit

connecting device according to the invention from the stack itself (and the relative

high-voltage terminal). In this manner, the surplus high-voltage terminal is actually

naturalized in permanent, simple and rapid manner, without the use of grounding wires

and without the need to internally modify the gas lighter device.

[0014] Further features and advantages of the present invention will be apparent from the

following description of a non-limitative embodiment thereof, with reference to the

accompanying drawings, in which:

- figure 1 diagrammatically shows a perspective three-quarters top view of a fast-fit

electric connecting device made according to the invention;

- figure 2 shows an orthogonal plan view from the bottom of the device in figure 1;

- figure 3 shows a section view taken along a plotting plane III-III of the device in

figure 2; and

- figures 4 and 5 show a perspective view (figure 5 is a magnified detail) of an example

of use and assembly of the connection device in figures 1-3.

[0015] With reference to figures from 1 to 5, numeral 1 indicates as a whole a device for

the fast-fit electrical connection of a high-voltage output terminal 2 of an electronic

gas lighter device 3 (of known type, e.g. from

EP 1101066B1, and which is thus not further described in detail for the sake of simplicity) to

an electrically conducting element 4 of an electric household appliance (known and

not shown for the sake of simplicity) against which the gas lighter device 3 is intended

in use to be integrally fixed, e.g. to a lower surface of a cooking range equipped

with a certain number of burners, known and not shown, or a part of the carcass of

the electric household appliance.

[0016] Electrically conducting element 4 is normally connected (in known manner and not

shown for the sake of simplicity) to a reference potential, i.e. it is electrically

"grounded", e.g. by means of part of the electric circuit within device 3 itself and,

as shown below, device 1 is used according to the invention (figures 4 and 5) to neutralize

the ground connection (by means of element 4) of an output terminal 2b (figure 5)

exceeding the number of high-voltage output terminals 2 of gas lighter device 3 needed

by the household appliance, e.g. exceeding the number of burners of the cooking range

forming conducting element 4 (in general).

[0017] According to an aspect of the invention, electric connecting device 1 consists of

a simple elastically deformable metallic foil, particularly shaped by folding over

the elastic limit, so as to comprise a U-shaped assembly portion 10, adapted to be

inserted in use in a contact carrier stack 11 (figure 5) of an electrically non-conducting

casing 12 (e.g. formed by an injection moulded synthetic plastic material) of the

gas lighter device 3; and furthermore so as to comprise a working portion defined

by an arm 14, which extends askew and cantilevered from a first end 15 of assembly

portion 10 and which is shaped so as to be adapted, in use, to cooperate in contact

against electrically conducting element 4 (figure 4).

[0018] Assembly portion 10 is provided with a slot 16 for the mechanical and electrical

coupling with respective terminal 2b of the blade type accommodated within contact

carrier stack 11 of casing 12, and a second end 18, opposite to end 15, adapted to

engage in use to engage an internal side wall 21 of contact carrier stack 11, also

consequent to an elastic deformation of foil 1 consequent to the reciprocal contact

in use between cantilevered arm 14 and electrically conducting element 4 of the electric

household appliance.

[0019] Specifically, assembly portion 10 is asymmetrically U-shaped, where first end 15

forms a side branch having longer length than the asymmetric U and second end 18 forms

an opposite side branch, having a shorter length than the asymmetric U.

[0020] Furthermore, slot 16 is made through an intermediate connection segment 22 of the

U between the longer and the shorter length side branches formed by ends 15 and 18,

and is transversally oriented with respect to cantilevered arm 14 forming the working

portion, displaying (figure 1) a longitudinal direction of extension (length) oriented

perpendicularly with respect to a longitudinal direction of extension (length) of

cantilevered arm 14, identifiable in figure 2 with a perpendicular to the plane of

the sheet and with the plane of the sheet, respectively.

[0021] Finally, slot 16 displays dimensions such as to couple in use with a predetermined

clearance with blade terminal 2b to be neutralized of gas lighter device 3; such predetermined

clearance is specifically of an order such that elastically formable foil 1 may oscillate

in use on blade terminal 2b to which it is coupled within contact carrier stack 11

so as to press second end 18 against side wall 21 of stack 11; for the same purpose,

assembly portion 10 is also preferably shaped so as to be coupled with a slight predetermined

clearance within stack 11. In this manner, a very high assembly ease of device 1 on

gas lighter device 3 is obtained, also in the presence of relatively high machining

tolerances without, on the other hand, the risk of leading the electrical connection

of terminal 2b with element 4 through blade 1 to fail, as shown below.

[0022] Second end 18 is preferably provided with at least one anchoring tooth 30, even more

preferably with a pair of anchoring teeth 30 side by side, for anchoring side wall

21, essentially isosceles-triangle-shaped, adapted to be driven into side wall 21

of contact carrier stack 11 of casing 12 in virtue of the fact that the latter, as

the entire casing 12, are formed by relatively soft synthetic plastic material with

respect to the metallic material with which elastically deformable foil 1 forming

the fast-fit electric connection device of the invention is made, typically steel

(or other alloy, e.g. even brass) of the harmonic type.

[0023] Anchoring tooth 30 or pair of teeth 30 to wall 21 is/are cantilevered at an end edge

32 of second end 18 of assembly portion 10, which edge 32 (figure 3) was folded askew

(with respect to the branch of the U defined by end 18 itself) on opposite side to

the skew and cantilevered direction of extension of opposite arm 14 defined by end

15.

[0024] Cantilevered skew arm 14 is in turn provided with a free end 40 folded so as to be

essentially parallel to respective side branches of U-shaped assembly portion 10 when

metallic foil 1 is in undeformed conditions (figure 3).

[0025] As shown in figures 4 and 5, fast-fit electric connecting device 1 in figures 1-3

described herein is used in an innovative manner according to the invention to effectively

neutralize a high-voltage output terminal 2b of electronic gas lighter device 3 exceeding

the number of high-voltage output terminals 2 needed by the electric household appliance,

by grounding terminal 2b (surplus with respect to the total number of existing terminals

2) with electrically conducting element 4 of the electric household appliance, against

which gas lighter device 3 is however intended to be integrally fixed in use.

[0026] The use according to the invention is characterised in that elastically deformable

foil 1 is integrally mounted onto gas lighter device 3 with its assembly portion 10

inserted against contact carrier stack 11 of casing 12 corresponding to surplus terminal

2b and throughly accommodating the same; furthermore, slot 16 is, in such configuration,

mechanically and electrically connected to surplus terminal 2b, which is throughly

inserted across the same in assembly portion 10.

[0027] Concurrently, in the configuration described and illustrated in figures 4 and 5,

arm 14 is arranged askew and cantilevered from contact carrier stack 11 accommodating

terminal 2b and extends laterally cantilevered, transversally with respect to a longitudinal

axis A of gas lighter device 3 and out of stack 11, so as to be distanced in cantilevered

manner from casing 12 askew with respect to aforesaid axis A and towards conducting

element 4.

[0028] Finally, the use of the invention provides for the fixing in a known manner (besides

necessary in any case) of gas lighter device 3 to electrically conducting element

4, performed so that arm 14 is pressed, at least with its free end 40, against electrically

conducting element 4 with a force such as to press for example by elastic reaction

and/or by oscillation of foil 1 on terminal 2b and in stack 11, second end 18 of assembly

portion 10 (in particular edge 32 with teeth 30) against side wall 21 of stack 11.

1. A device (1) for the fast-fit electric connection of a high-voltage output terminal

(2) of an electronic gas lighter (3) to an electric conducting element (4) of an electric

household appliance upon which the gas lighter is intended in use to be integrally

fastened, for example a cooking range, in particular for neutralisation by grounding

connection of an output terminal (2b) exceeding the number of high-voltage output

terminals (2) of the gas lighter (3) needed by the electric household appliance; characterised in that it consists of an elastically deformable metallic foil (1) comprising: a U-shaped

assembly portion (10), adapted to be inserted in a contact carrier stack (11) of an

electrically non-conducting casing (12) of the gas lighter; and a working portion

defined by an arm (14), which extends askew and cantilevered from a first end (15)

of the assembly portion and which is shaped so as to be adapted, in use, to cooperate

in contact against the conducting element (4); the assembly portion (10) being provided

with a slot (16) for mechanical and electrical coupling with a respective blade terminal

(2) accommodated within said contact carrier stack of the gas lighter casing, and

a second end (18) opposite to the first and adapted to engage in use an internal side

wall (21) of the contact carrier stack, consequent to the reciprocal contact between

said cantilevered arm (14) of the working portion and the electrically conducting

element (4) of the electric household appliance.

2. A device according to claim 1, characterised in that said assembly portion (10) is asymmetrically U-shaped, said first end (15) forming

a side branch of a longer length of the asymmetric U and said second end (18) forming

an opposite side branch, of a shorter length of the asymmetric U.

3. A device according to claim 2, characterised in that said slot (16) for coupling with said blade contact of the gas lighter is made through

an intermediate connection segment (22) of the U between said longer side branch and

said shorter side branch.

4. A device according to any of the preceding claims, characterised in that said slot (16) for coupling with said blade contact of the gas lighter is transversally

oriented with respect to said cantilevered arm (14) of the working portion, presenting

a longitudinal direction of extension oriented perpendicularly with respect to a longitudinal

direction of extension of the cantilevered arm (14).

5. A device according to claim 4, characterised in that said slot (16) presents size so as to couple in use with predetermined clearance

with the blade contact (2b) of the gas lighter; said predetermined clearance being

such that said elastically deformable foil (1) may oscillate in use on the blade contact

(2b) which is coupled within said contact carrier stack so as to press said second

end (18) of said assembly portion against said side wall (21) of the stack, in particular

consequent to an elastic deformation of the foil (1).

6. A device according to one of the preceding claims, characterised in that said second end (18) of the assembly portion of said elastically deformable metallic

foil (1) is provided with at least one anchoring tooth (30), preferably with a pair

of anchoring teeth (30), to said side wall (21) of the contact carrier stack.

7. A device according to claim 6, characterised in that said at least one anchoring tooth (30) is adapted to be driven into said side wall

(21) of the contact carrier stack of the casing of the gas lighter; said casing (12)

being made of relatively soft synthetic plastic material relatively to the metallic

material with which said elastically deformable foil (1) is made.

8. A device according to claim 6 or 7, characterised in that said at least one anchoring tooth (30) is cantilevered at an end edge (32) of said

second end of the assembly portion folded askew on opposite side to the skew and cantilevered

direction of extension of said arm (14) of the working position of the elastic foil.

9. A device according to any of the preceding claims, characterised in that said cantilevered skew arm (14) is provided with a free end (40) folded so as to

be essentially parallel to respective side branches of the U-shaped assembly portion

(10) when the metallic foil is not deformed.

10. Use of a quick electric connection device (1) according to any of the preceding claims,

for neutralization of a high-voltage output terminal (2b) of an electronic gas lighter

(3) for an electric household appliance, exceeding the number of high-voltage terminals

(2) needed by the electric household appliance, by electric grounding connection of

the surplus terminal (2b) with an electric connecting element (4) of the electric

household appliance against which the gas lighter (3) is intended in use to be integrally

fastened; said use being characterised in that the elastically deformable foil (1) is integrally fitted to the gas lighter (3) with

its assembly portion (10) inserted in a contact carrier stack (11) of an electrically

non-conducting casing (12) of the gas lighter (3) accommodating the surplus terminal

(2b), mechanically and electrically connected to the surplus terminal (2b) by means

of said slot (16) in the assembly portion (10) and with said arm (14) in working position

askew protruding from the contact carrier stack (11); and by fastening said gas lighter

(3) to said electrically conducting element (4) so that said arm (14) is pressed at

least with one its free end (40) against the electric conducting element (4) with

such a force to press said second end (18) of the assembly portion (10) against a

side wall (21) of the contact carrier stack (11).

1. Vorrichtung (1) für die elektrische Verbindung mit schneller Montage eines Hochspannungs-Ausgangsanschlusses

(2) eines elektronischen Gasanzünders (3) mit einem elektrisch leitenden Element (4)

eines elektrischen Haushaltsgeräts, z. B. eines Kochherds, wobei vorgesehen ist, dass

der Gasanzünder in Gebrauch einteilig an ihm befestigt ist, insbesondere für die Neutralisation

durch eine Erdungsverbindung eines Ausgangsanschlusses (2b), der die Anzahl der Hochspannungsausgangsanschlüsse

(2) des Gasanzünders (3) übersteigt, die durch das elektrische Haushaltsgerät benötigt

werden; dadurch gekennzeichnet, dass sie aus einer elastisch verformbaren Metallfolie (1) besteht, die Folgendes umfasst:

einen U-förmigen Montageabschnitt (10), der beschaffen ist, um in einen Kontaktträgerstapel

(11) eines elektrisch nichtleitenden Gehäuses (12) des Gasanzünders eingesetzt zu

werden; und einen Arbeitsabschnitt, der durch einen Arm (14) definiert ist, der schief

und freitragend von einem ersten Ende (15) des Montageabschnitts verläuft und der

geformt ist, um in Gebrauch beschaffen zu sein, in Kontakt mit dem leitenden Element

(4) zusammenzuwirken; wobei der Montageabschnitt (10) mit einem Schlitz (16) für die

mechanische und elektrische Kopplung an einen entsprechenden Flachstecker (2), der

in dem Kontaktträgerstapel des Gasanzündergehäuses untergebracht ist, und einem zweiten

Ende (18), das dem ersten Ende gegenüberliegt und beschaffen ist, um in Gebrauch dem

wechselseitigen Kontakt zwischen dem freitragenden Arm (14) des Arbeitsabschnitts

und dem elektrisch leitenden Element (4) des elektrischen Haushaltsgeräts folgend

mit einer inneren Seitenwand (21) des Kontaktträgerstapels in Eingriff zu gelangen,

versehen ist.

2. Vorrichtung nach Anspruch 1, dadurch gekennzeichnet, dass der Montageabschnitt (10) asymmetrisch U-förmig ist, das erste Ende (15) einen Seitenzweig

mit einer größeren Länge des asymmetrischen U bildet und das zweite Ende (18) einen

gegenüberliegenden Seitenzweig mit einer kürzeren Länge des asymmetrischen U bildet.

3. Vorrichtung nach Anspruch 2, dadurch gekennzeichnet, dass der Schlitz (16) für die Kopplung mit dem Messerkontakt des Gasanzünders durch ein

Zwischenverbindungssegment (22) des U zwischen dem längeren Seitenzweig und dem kürzeren

Seitenzweig hergestellt ist.

4. Vorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der Schlitz (16) für die Kopplung mit dem Messerkontakt des Gasanzünders bezüglich

des freitragenden Arms (14) des Arbeitsabschnitts transversal orientiert ist, was

eine Längsrichtung der Ausdehnung darstellt, die senkrecht bezüglich einer Längsrichtung

der Ausdehnung des freitragenden Arms (14) orientiert ist.

5. Vorrichtung nach Anspruch 4, dadurch gekennzeichnet, dass der Schlitz (16) eine Größe darstellt, um in Gebrauch mit einem vorgegebenen Zwischenraum

an den Messerkontakt (2b) des Gasanzünders gekoppelt zu sein; wobei der vorgegebene

Zwischenraum derart ist, dass die elastisch verformbare Folie (1) in Gebrauch an dem

Messerkontakt (2b) oszillieren kann, der in dem Kontaktträgerstapel gekoppelt ist,

um das zweite Ende (18) des Montageabschnitts gegen die Seitenwand (21) des Stapels

zu drücken, insbesondere einer elastischen Information der Folie (1) folgend.

6. Vorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass das zweite Ende (18) des Montageabschnitts der elastisch verformbaren Metallfolie

(1) mit wenigstens einem Verankerungszahn (30), vorzugsweise mit einem Paar Verankerungszähnen

(30) zu der Seitenwand (21) des Kontaktträgerstapels versehen ist,

7. Vorrichtung nach Anspruch 6, dadurch gekennzeichnet, dass der wenigstens eine Verankerungszahn (30) beschaffen ist, um in die Seitenwand (21)

des Kontaktträgerstapels des Gehäuses des Gasanzünders getrieben zu werden; wobei

das Gehäuse (12) aus einem relativ weichen synthetischen Kunststoffmaterial im Verhältnis

zu dem Metallmaterial hergestellt ist, aus dem die elastisch verformbare Folie (1)

hergestellt ist.

8. Vorrichtung nach Anspruch 6 oder 7, dadurch gekennzeichnet, dass der wenigstens eine Verankerungszahn (30) an einer Endkante (32) des zweiten Endes

des Zusammenbauabschnitts, der schief auf einer gegenüberliegenden Seite zu der schräg

verlaufenden und freitragenden Richtung der Ausdehnung des Arms (14) der Arbeitsposition

der elastischen Folie gefaltet ist, freitragend ist.

9. Vorrichtung nach einem der vorhergehenden Ansprüche, dadurch gekennzeichnet, dass der freitragende schräg verlaufende Arm (14) mit einem freien Ende (40) versehen

ist, das so gefaltet ist, um im Wesentlichen parallel zu den jeweiligen Seitenzweigen

des U-förmigen Montageabschnitts (10) zu sein, wenn die Metallfolie nicht verformt

ist.

10. Verwendung einer Vorrichtung (1) für die schnelle elektrische Verbindung nach einem

der vorhergehenden Ansprüche für die Neutralisation eines Hochspannungs-Ausgangsanschlusses

(2b) eines elektrischen Gasanzünders (3) für ein elektrisches Haushaltsgerät, der

die Anzahl der Hochspannungsanschlüsse (2), die durch das elektrische Haushaltsgerät

benötigt werden, übersteigt, durch die elektrische Erdungsverbindung des überschüssigen

Anschlusses (2b) mit einem elektrischen Verbindungselement (4) des elektrischen Haushaltsgeräts,

wobei vorgesehen ist, dass der Gasanzünder (3) in Gebrauch einteilig an ihm befestigt

ist; wobei die Verwendung dadurch gekennzeichnet ist, dass die elastisch verformbare Folie (1) einteilig an den Gasanzünder (3) montiert ist,

wobei ihr Montageabschnitt (10) in einen Kontaktträgerstapel (11) eines elektrisch

nichtleitenden Gehäuses (12) des Gasanzünders (3), das den überschüssigen Anschluss

(2b) aufnimmt, eingesetzt ist, mechanisch und elektrisch mit dem überschüssigen Anschluss

(2b) mittels des Schlitzes (16) in dem Montageabschnitt (10) verbunden ist und wobei

der Arm (14) in der Arbeitsposition von dem Kontaktträgerstapel (11) schief vorsteht;

und durch das Befestigen des Gasanzünders (3) an dem elektrisch leitenden Element

(4), so dass der Arm (14) wenigstens mit seinem einen freien Ende (40) gegen das elektrisch

leitende Element (4) mit einer derartigen Kraft gedrückt wird, um das zweite Ende

(18) des Montageabschnitts (10) gegen eine Seitenwand (21) des Kontaktträgerstapels

(11) zu drücken.

1. Dispositif (1) pour la connexion électrique rapide d'une borne de sortie haute tension

(2) d'un allumeur de gaz électronique (3) à un élément conducteur électrique (4) d'un

appareil domestique électrique sur lequel l'allumeur de gaz est destiné à être fixé

solidairement en service, par exemple une cuisinière, en particulier pour la neutralisation

par connexion de mise à la terre d'une borne de sortie (2b) dépassant le nombre de

bornes de sortie haute tension (2) de l'allumeur de gaz (3) dont l'appareil domestique

a besoin ; caractérisé en ce qu'il consiste en une feuille métallique élastiquement déformable (1) comprenant : une

partie d'assemblage en forme de U (10), adaptée pour être insérée dans un bloc porte-contact

(11) d'un boîtier électriquement non conducteur (12) de l'allumeur de gaz ; et une

partie de travail définie par un bras (14), qui s'étend en biais et en porte-à-faux

depuis une première extrémité (15) de la partie d'assemblage et qui est formé de manière

à être adapté, en service, de façon à coopérer en contact contre l'élément conducteur

(4) ; la partie d'assemblage (10) étant pourvue d'une fente (16) pour le couplage

mécanique et électrique avec une borne à couteau respective (2) logée à l'intérieur

dudit bloc porte-contact du boîtier de l'allumeur de gaz, et d'une deuxième extrémité

(18) en face de la première et adaptée de façon à s'engager en service avec une paroi

latérale interne (21) du bloc porte-contact, par suite du contact réciproque entre

ledit bras en porte-à-faux (14) de la partie de travail et l'élément électriquement

conducteur (4) de l'appareil domestique électrique.

2. Dispositif selon la revendication 1, caractérisé en ce que ladite partie d'assemblage (10) est formée en U asymétriquement, ladite première

extrémité (15) formant une branche latérale d'une longueur plus grande de l'U asymétrique

et ladite deuxième extrémité (18) formant une branche latérale opposée, d'une longueur

plus courte de l'U asymétrique.

3. Dispositif selon la revendication 2, caractérisé en ce que ladite fente (16) pour le couplage avec ledit contact à couteau de l'allumeur de

gaz est faite à travers un segment de connexion intermédiaire (22) de l'U entre ladite

branche latérale plus longue et ladite branche latérale plus courte.

4. Dispositif selon l'une quelconque des revendications précédentes, caractérisé en ce que ladite fente (16) pour le couplage avec ledit contact à couteau de l'allumeur de

gaz est orientée transversalement par rapport audit bras en porte-à-faux (14) de la

partie de travail, présentant une direction longitudinale d'extension orientée perpendiculairement

par rapport à une direction longitudinale d'extension du bras en porte-à-faux (14).

5. Dispositif selon la revendication 4, caractérisé en ce que ladite fente (16) présente une taille de manière à se coupler, en service, avec un

jeu prédéterminé avec le contact à couteau (2b) de l'allumeur de gaz ; ledit jeu prédéterminé

étant tel que ladite feuille déformable élastiquement (1) peut osciller en service

sur le contact à couteau (2b) qui est couplé à l'intérieur dudit bloc porte-contact

de façon à presser ladite deuxième extrémité (18) de ladite partie d'assemblage contre

ladite paroi latérale (21) du bloc, en particulier par suite d'une déformation élastique

de la feuille (1).

6. Dispositif selon l'une quelconque des revendications précédentes, caractérisé en ce que ladite deuxième extrémité (18) de la partie d'assemblage de ladite feuille métallique

déformable élastiquement (1) est pourvue d'au moins une dent d'ancrage (30), de préférence

d'une paire de dents d'ancrage (30), à ladite paroi latérale (21) du bloc porte-contact.

7. Dispositif selon la revendication 6, caractérisé en ce que ladite au moins une dent d'ancrage (30) est adaptée de façon à être enfoncée dans

ladite paroi latérale (21) du bloc porte-contact du boîtier de l'allumeur de gaz ;

ledit boîtier (12) étant fait en une matière plastique synthétique relativement molle

par rapport au matériau métallique avec lequel ladite feuille déformable élastiquement

(1) est faite.

8. Dispositif selon la revendication 6 ou 7, caractérisé en ce que ladite au moins une dent d'ancrage (30) est en porte-à-faux à un bord extrême (32)

de ladite deuxième extrémité de la partie d'assemblage pliée en biais sur le côté

opposé à la direction d'extension en biais et en porte-à-faux dudit bras (14) de la

position de travail de la feuille élastique.

9. Dispositif selon l'une quelconque des revendications précédentes, caractérisé en ce que ledit bras en biais en porte-à-faux (14) est pourvu d'une extrémité libre (40) pliée

de façon à être essentiellement parallèle aux branches latérales respectives de la

partie d'assemblage en forme de U (10) lorsque la feuille métallique n'est pas déformée.

10. Utilisation d'un dispositif de connexion électrique rapide selon l'une quelconque

des revendications précédentes, pour la neutralisation d'une borne de sortie haute

tension (2b) d'un allumeur de gaz électronique (3) pour un appareil domestique électrique,

dépassant le nombre de bornes haute tension (2) dont a besoin l'appareil domestique,

par la connexion de mise à la terre électrique de la borne en surplus (2b) avec un

élément de connexion électrique (4) de l'appareil domestique électrique contre lequel

l'allumeur de gaz (3) est destiné à être fixé solidairement en service ; ladite utilisation

étant caractérisée en ce que la feuille élastiquement déformable (1) est montée solidairement sur l'allumeur de

gaz (3) avec sa partie d'assemblage (10) insérée dans un bloc porte-contact (11) d'un

boîtier électriquement non conducteur (12) de l'allumeur de gaz (3) dans lequel se

trouve la borne en surplus (2b), raccordée mécaniquement et électriquement à la borne

en surplus (2b) au moyen de ladite fente (16) dans la partie d'assemblage (10) et

avec ledit bras (14) dans la position de travail en biais faisant saillie du bloc

porte-contact (11) ; et en fixant ledit allumeur de gaz (3) audit élément électriquement

conducteur (4) de manière à ce que ledit bras (14) soit pressé au moins avec une son

extrémité libre (40) contre l'élément conducteur électrique (4) avec une force telle

à presser la deuxième extrémité (18) de la partie d'assemblage (10) contre une paroi

latérale (21) du bloc porte-contact (11).

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the reader's convenience only.

It does not form part of the European patent document. Even though great care has

been taken in compiling the references, errors or omissions cannot be excluded and

the EPO disclaims all liability in this regard.

Patent documents cited in the description