| (19) |

|

|

(11) |

EP 2 159 811 B1 |

| (12) |

EUROPEAN PATENT SPECIFICATION |

| (45) |

Mention of the grant of the patent: |

|

01.05.2013 Bulletin 2013/18 |

| (22) |

Date of filing: 01.09.2008 |

|

| (51) |

International Patent Classification (IPC):

|

|

| (54) |

High voltage circuit breaker

Hochspannungsschutzschalter

Disjoncteur haute tension

|

| (84) |

Designated Contracting States: |

|

AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LI LT LU LV MC MT NL NO PL

PT RO SE SI SK TR |

| (43) |

Date of publication of application: |

|

03.03.2010 Bulletin 2010/09 |

| (73) |

Proprietor: ABB Technology AG |

|

8050 Zürich (CH) |

|

| (72) |

Inventor: |

|

- Lidholm, Johan

777 51 Smedjebacken (SE)

|

| (74) |

Representative: Kock, Ina |

|

ABB AB

Intellectual Property

Ingenjör Bååths Gata 11

721 83 Västerås

721 83 Västerås (SE) |

| (56) |

References cited: :

EP-A- 0 077 516

|

US-A- 3 504 142

|

|

| |

|

|

|

|

| |

|

| Note: Within nine months from the publication of the mention of the grant of the European

patent, any person may give notice to the European Patent Office of opposition to

the European patent

granted. Notice of opposition shall be filed in a written reasoned statement. It shall

not be deemed to

have been filed until the opposition fee has been paid. (Art. 99(1) European Patent

Convention).

|

FIELD OF INVENTION

[0001] The present invention relates to a high voltage live tank circuit breaker.

BACKGROUND OF THE INVENTION

[0002] Electrical power transmission networks are protected and controlled by high voltage

circuit breakers. Such circuit breakers are divided in two classes: live tank circuit

breakers (LTB) where the enclosure that contains the breaking mechanism is at line

potential and the dead tank circuit breakers (DTB) where the enclosures are at earth

potential.

[0003] The live tank circuit breakers at high voltage levels have to handle the high potential

at the terminal electrodes where the tubes or cables are connected to pass the current

through the circuit breaker. The high potential creates high electrical field stress

at the terminal electrodes. Commonly the terminal electrodes are shielded with corona

rings, which purpose is to reduce the local electrical field stress by their smooth

shape and relatively large area compared to the terminals.

[0004] Two different corona ring designs are common. Either the corona rings are placed

as close to the terminal electrode as possible. If capacitors or pre-insertion resistors

are used the same philosophy is used. Alternatively, a circular corona ring is placed

symmetrically around the circuit breaker center axis.

[0005] The live tank circuit breaker external isolation media is air. The external insulation

is verified with dielectric tests following the requirements in applicable standards.

These verifying tests for high voltage circuit breakers include both dry and wet tests

since the high voltage circuit breaker is an out door equipment.

[0006] An example of circuit breaker with corona ring around the treminals is disclosed

in

US-A-3504142.

SUMMARY OF THE INVENTION

[0007] During such wet tests the rain is collected all over the surface of the circuit breaker

and the corona rings. The water is pouring downwards on the surface and collected

at the lowest position on each individual part of the circuit breaker and finally

it is falling of the surface towards ground.

[0008] The water drops will be affected by the high voltage and change shape; they will

be sharper then normal and increase the local electrical field stress.

[0009] The invention is based on the fact that during switching over voltages during wet

conditions the local electrical field at the corona rings lower part will increase

in comparison to dry conditions.

[0010] An object of the present invention is therefore to provide a high voltage live tank

circuit breaker with an improved dielectric withstand capability, in particular during

wet conditions.

[0011] A further object of the invention is to provide such a high voltage circuit breaker,

which is robust, accurate, uncomplicated, space-saving, and inexpensive, and which

has an optimum performance and which fulfills existing safety requirements.

[0012] A yet further object of the invention is to provide a method for preparing a high

voltage circuit breaker which fulfills any of the above objects.

[0013] These objects are attained by high voltage circuit breakers and methods as claimed

in the appended patent claims.

[0014] According to a first aspect of the invention there is provided a high voltage live

tank circuit breaker comprising a support insulator, an elongated current interrupter

provided on the support insulator, terminals connected to the ends of the current

interrupter, and at least one corona ring arranged to at least partly surround at

least one of the terminals.

[0015] The corona ring is provided with a hydrophobic surface layer to thereby obtain a

high voltage live tank circuit breaker with improved dielectric withstand capability

in wet conditions.

[0016] The wet conditions are the most severe and at the same time the hardest to theoretically

calculate and dimension for each circuit breaker design. Different designs have therefore

been experimentally tested in a high voltage laboratory and it has been found that

the critical factor is the number and size of the water drops on the surface of the

corona rings. A considerable improvement is obtained by the using the invention. The

number and size of the water drops are considerably reduced.

[0017] In one embodiment the high voltage live tank circuit breaker comprises a horizontally

arranged elongated current interrupter, and a horizontally arranged elongated capacitor

and/or resistor connected between the terminals in parallel with the current interrupter,

wherein the parts are so arranged that the vertical distance between the inner surface

of the lower end of the corona ring and a center axis of the current interrupter,

the capacitor, if present, or the resistor, if present, whichever being located lowest,

is between about 1.5 and about 4 times shorter than the distance between the inner

surface of the upper end of the corona ring and the center axis.

[0018] Hereby, a more evenly distributed electrical field around the corona ring is obtained

in presence of water, and as a result, the dielectric withstand capability in wet

conditions is further improved.

[0019] According to a second aspect of the invention there is provided a method for preparing

a high voltage live tank circuit breaker comprising a support insulator, an elongated

current interrupter provided on the support insulator, terminals connected to the

ends of the current interrupter, and at least one corona ring arranged to at least

partly surround at least one of the terminals. According to the method, the corona

ring is provided with a hydrophobic surface layer.

[0020] Preferably, the hydrophobic surface layer is provided by means of spraying or coating

the corona ring with hydrophobic material such as silicone rubber or a resin such

as a fluorine or silicone resin.

[0021] Further characteristics of the invention and advantages thereof, will be evident

from the following detailed description of preferred embodiments of the present invention

given hereinafter and the accompanying Figs. 1-2, which are given by way of illustration

only and are thus not limitative of the present invention.

BRIEF DESCRIPTION OF THE DRAWINGS

[0022]

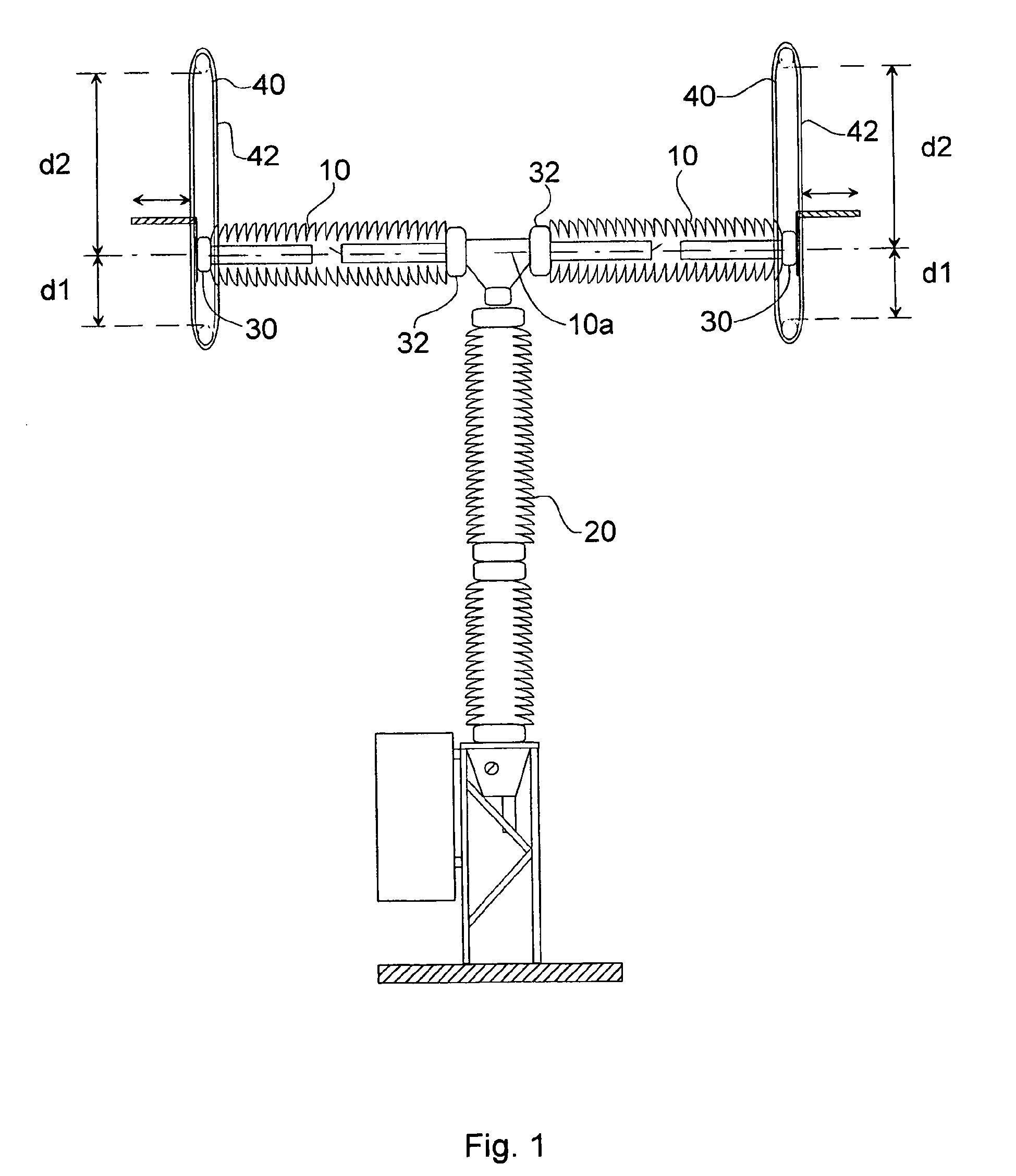

Fig. 1 illustrates schematically in a side elevation view a high voltage circuit breaker

according to an embodiment of the invention.

Fig. 2 illustrates schematically in an end view a current interrupter and a corona

ring as being comprised in the high voltage circuit breaker of Fig. 1.

DETAILED DESCRIPTION OF EMBODIMENTS

[0023] In the following a detailed description of preferred embodiments of the present invention

will be given. In this description, the term

high voltage will be used for voltages of 1 kV and higher. It shall, however, be noted that the

present invention is primarily intended for high voltage circuit breakers with much

higher voltage ratings, such as 245 kV and above.

[0024] Fig. 1 illustrates schematically in a side elevation view a one-phase high voltage

live tank circuit breaker, which comprises two horizontally arranged and serially

connected elongated current interrupters 10 arranged on a support insulator 20. The

current interrupters 10 may be referred to as breaker or extinguishing chambers and

the assembly of two current interrupters 10 may be referred to as a breaking unit.

Each of the current interrupters 10 is connected to a terminal 30 at its far end and

to a connection flange 32 at its inner end.

[0025] Further, the circuit breaker comprises a respective corona ring 40 arranged to at

least partly surround the terminal 30 connected to the far ends of the serially interconnected

current interrupters 10, that is, typically no corona rings are arranged around the

connection flanges 32, which interconnects the current interrupters 10.

[0026] Fig. 2 illustrates schematically in an end view one of the current interrupters 10

and one of the corona rings 40 of the high voltage circuit breaker of Fig. 1. The

supports 41 holding the corona ring 40 are illustrated.

[0027] According to the invention one or preferably each of the corona rings 40 is provided

with a hydrophobic surface layer 42.

[0028] Preferably, the hydrophobic surface layer 42 is applied by means of spraying or coating

the corona ring(s) 42 with hydrophobic material such as a rubber or a resin material,

e.g. a silicone rubber or a fluorine or silicone resin.

[0029] The hydrophobic surface layer 42 may cover essentially the entire surface of the

corona ring(s) 40 or only portions of the surface of the corona ring(s) 40, preferably

lower portions of the surface of the corona ring(s) 42.

[0030] For illustrative purposes the thickness of the layer 42 is highly exaggerated in

Figs. 1-2.

[0031] It shall be appreciated that the corona rings 40 may be closed or open-ended and

they can have different shapes, though the corona rings 40 in Figs. 1-2 are torus

shaped.

[0032] Provided that the corona rings are arranged symmetrically around the current interrupters

10 in the lateral plane the sum of distances d1 and d2 corresponds to the inner diameter

of the corona rings 40.

[0033] It shall further be appreciated that there can be arranged more corona rings around

each terminal. Commonly, the corona rings are provided in pairs with a short fixed

distance in between.

[0034] Further, in one version of the invention, one or each of the corona rings is located

such that the vertical distance d1 between the inner surface of the lower end of the

corona ring 40 and a center axis 10a of the current interrupter 10 is between about

1.5 and about 4 times shorter than the distance d2 between the inner surface of the

upper end of the corona ring 40 and the center axis 10a.

[0035] If the circuit breaker, for each current interrupter, comprises a horizontally arranged

elongated capacitor and/or resistor connected between the terminals in parallel with

the current interrupter, each corona ring is preferably arranged such that the vertical

distance between the inner surface of the lower end of the corona ring 40 and a center

axis of the current interrupter 10, of the elongated capacitor, or of the resistor,

whichever being located lowest, is between about 1.5 and about 4 times shorter than

the distance between the inner surface of the upper end of the corona ring and that

center axis.

[0036] By using the new design a higher dielectric withstand capability to withstand both

the switching and lightning impulse voltage is obtained, especially during wet conditions.

[0037] A three-phase high voltage live tank circuit breaker comprises three of the circuit

breaker as disclosed above.

1. A high voltage live tank circuit breaker comprising:

- a support insulator (20);

- at least one elongated current interrupter (10) provided on said support insulator

(20);

- terminals (30) connected to the ends of said current interrupter; and

- at least one corona ring (40) arranged to at least partly surround one of the terminals,

characterised in that

- said corona ring (40) is provided with a hydrophobic surface layer (42).

2. The circuit breaker of claim 1 wherein said hydrophobic surface layer (42) is made

of any of a rubber or a resin material such as e.g. a silicone rubber or a fluorine

or silicone resin.

3. The circuit breaker of claim 1 or 2 wherein said hydrophobic surface layer (42) covers

essentially the entire surface of said corona ring.

4. The circuit breaker of claim 1 or 2 wherein said hydrophobic surface layer (42) covers

only portions of the surface of said corona ring, preferably lower portions of the

surface of said corona ring.

5. The circuit breaker of any of claims 1-4 wherein the corona ring is open-ended.

6. The circuit breaker of any of claims 1-5 comprising a further corona ring arranged

to at least partly surround said one of the terminals, the corona rings being arranged

concentrically with respect to one another.

7. The circuit breaker of any of claims 1-6 comprising a corona ring arranged to at least

partly surround another one of the terminals, the corona rings being arranged concentrically

with respect to one another.

8. The circuit breaker of any of claims 1-7 comprising a further elongated current interrupter

(10) and terminals (30) connected to the ends of the current interrupter, the current

interrupters being arranged concentrically with respect to one another and being serially

connected, wherein said one of the terminals, which is at least partly surrounded

by the corona ring (40), is an outer terminal of said serially connected current interrupters;

and further comprising a corona ring (40) arranged to at least partly surround the

other outer terminal of said serially connected current interrupters and being provided

with a hydrophobic surface layer (42), the corona rings being arranged concentrically

with respect to one another.

9. The circuit breaker of any of claims 1-7 wherein said elongated current interrupter

is arranged essentially horizontally and said corona ring is arranged such that the

vertical distance (d1) between the inner surface of the lower end of said corona ring

and a center axis (10a) of said essentially horizontally arranged elongated current

interrupter (10) is between about 1.5 and about 4 times shorter than the distance

(d2) between the inner surface of the upper end of said corona ring and said center

axis.

10. The circuit breaker of any of claims 1-7 comprising an essentially horizontally arranged

elongated capacitor (50) and/or resistor (60) connected between the terminals in parallel

with the current interrupter (10), which is essentially horizontally arranged, wherein

said corona ring (40) is arranged such that the vertical distance (d1) between the

inner surface of the lower end of said corona ring and a center axis (10a) of said

essentially horizontally arranged elongated current interrupter (10), of said essentially

horizontally arranged elongated capacitor (50), or of said essentially horizontally

arranged elongated resistor (60), whichever being located lowest, is between about

1.5 and about 4 times shorter than the distance (d2) between the inner surface of

the upper end of said corona ring and said center axis.

11. a three-phase high voltage live tank circuit breaker comprising three of the circuit

breaker of any of claims 1-10, one for each phase.

12. A method for preparing a high voltage live tank circuit breaker comprising a support

insulator (20); at least one elongated current interrupter (10) provided on said support

insulator (20); terminals (30) connected to the ends of said current interrupter;

and at least one corona ring (40) arranged to at least partly surround one of the

terminals, said method being

characterised by the step of

- providing said at least one corona ring (40) with a hydrophobic surface layer (42).

13. The method of claim 12 wherein the step of providing comprises spraying or coating

said at least one corona ring with hydrophobic material.

14. The method of claim 12 or 13 wherein said hydrophobic surface layer (42) is made of

any of a rubber or a resin material such as e.g. a silicone rubber or a fluorine or

silicone resin.

1. Hochspannungs-Schaltkammerleistungsschalter, umfassend:

- einen Stützisolator (20);

- mindestens einen gestreckten Stromunterbrecher (10), der an dem Stützisolator (20)

zur Verfügung gestellt ist;

- Anschlüsse (30), die mit den Enden des Stromunterbrechers verbunden sind; und

- mindestens ein Koronaring (40), der zum zumindest teilweise Umgeben eines der Anschlüsse

ausgelegt ist,

dadurch gekennzeichnet, dass

- der Koronaring (40) mit einer hydrophoben Oberflächenschicht (42) versehen ist.

2. Leistungsschalter nach Anspruch 1, wobei die hydrophobe Oberflächenschicht (42) aus

einem Gummi- oder einem Harzmaterial hergestellt ist, wie zum Beispiel einem Silikongummi

oder einem Fluor- oder Silikonharz.

3. Leistungsschalter nach Anspruch 1 oder 2, wobei die hydrophobe Oberflächenschicht

(42) im Wesentlichen die ganze Oberfläche des Koronarings bedeckt.

4. Leistungsschalter nach Anspruch 1 oder 2, wobei die hydrophobe Oberflächenschicht

(42) nur Abschnitte der Oberfläche des Koronarings bedeckt, vorzugsweise untere Abschnitte

der Oberfläche des Koronarings.

5. Leistungsschalter nach einem der Ansprüche 1-4, wobei der Koronaring offen ist.

6. Leistungsschalter nach einem der Ansprüche 1-5, der einen weiteren Koronaring umfasst,

welcher zum zumindest teilweisen Umgeben eines der Anschlüsse ausgelegt ist, wobei

die Koronaringe konzentrisch zueinander angeordnet sind.

7. Leistungsschalter nach einem der Ansprüche 1-6, der einen Koronaring umfasst, welcher

zum zumindest teilweisen Umgeben eines Weitern der Anschlüsse ausgelegt ist, wobei

die Koronaringe konzentrisch zueinander angeordnet sind.

8. Leistungsschalter nach einem der Ansprüche 1-7, der einen weiteren gestreckten Stromunterbrecher

(10) und Anschlüsse (30) umfasst, die mit den Enden des Stromunterbrechers verbunden

sind, wobei die Stromunterbrecher konzentrisch zueinander angeordnet sind und in Reihe

geschaltet sind, wobei einer der Anschlüsse, der zumindest teilweise vom Koronaring

(40) umgeben ist, ein äußerer Anschluss der in Reihe geschalteten Stromunterbrecher

ist; und der ferner einen Koronaring (40) umfasst, welcher zum zumindest teilweisen

Umgeben des anderen äußeren Anschlusses der in Reihe geschalteten Stromunterbrecher

angeordnet ist und der mit einer hydrophoben Oberflächenschicht (42) versehen ist,

wobei die Koronaringe konzentrisch zueinander angeordnet sind.

9. Leistungsschalter nach einem der Ansprüche 1-7, wobei der gestreckte Stromunterbrecher

im Wesentlichen horizontal angeordnet ist und der Koronaring so angeordnet ist, dass

der vertikale Abstand (d1) zwischen der Innenfläche des unteren Endes des Koronarings

und einer Mittelachse (10a) des im Wesentlichen horizontal angeordneten gestreckten

Stromunterbrechers (10) zwischen etwa 1,5-mal und etwa 4-mal kürzer als der Abstand

(d2) zwischen der Innenfläche des oberen Endes des Koronarings und der Mittelachse

ist.

10. Leistungsschalter nach einem der Ansprüche 1-7, der einen im Wesentlichen horizontal

angeordneten gestreckten Kondensator (50) und/oder Widerstand (60) umfasst, welcher

zwischen den Anschlüssen parallel zum Stromunterbrecher (10) liegt, der im Wesentlichen

horizontal angeordnet ist, wobei der Koronaring (40) derart angeordnet ist, dass der

vertikale Abstand (d1) zwischen der Innenfläche des unteren Endes des Koronarings

und einer Mittelachse (10a) des im Wesentlichen horizontal angeordneten gestreckten

Stromunterbrechers (10), des im Wesentlichen horizontal angeordneten gestreckten Kondensators

(50) oder des im Wesentlichen horizontal angeordneten gestreckten Widerstandes (60),

je nachdem, welcher am tiefsten angeordnet ist, etwa 1,5-mal bis etwa 4-mal kürzer

als der Abstand (d2) zwischen der Innenfläche des oberen Endes des Koronarings und

der Mittelachse ist.

11. Dreiphasen-Hochspannungs-Schaltkammerleistungsschalter, der drei der Leistungsschalter

nach einem der Ansprüche 1-10 umfasst, einer für jede Phase.

12. Verfahren zum Bereitstellen eines Hochspannungs-Schaltkammerleistungsschalters, der

einen Stützisolator (20); mindestens einen gestreckten Stromunterbrecher (10), der

an dem Stützisolator (20) zur Verfügung gestellt ist; Anschlüsse (30), die mit den

Enden des Stromunterbrechers verbunden sind; und mindestens einen Koronaring (40)

umfasst, der zum zumindest teilweise Umgeben eines der Anschlüsse ausgelegt ist, wobei

das Verfahren durch den folgenden Schritt gekennzeichnet ist:

- Bereitstellen des mindestens einen Koronarings (40) mit einer hydrophoben Oberflächenschicht

(42).

13. Verfahren nach Anspruch 12, wobei der Schritt des Bereitstellens das Besprühen oder

Beschichten des mindestens einen Koronarings mit hydrophobem Material umfasst.

14. Verfahren nach Anspruch 12 oder 13, wobei die hydrophobe Oberflächenschicht (42) aus

einem Gummi- oder einem Harzmaterial hergestellt ist, wie zum Beispiel einem Silikongummi

oder einem Fluor- oder Silikonharz.

1. Disjoncteur à haute tension à réservoir vivant, comprenant :

- un isolateur (20) de support ;

- au moins un interrupteur allongé (10) de courant, prévu sur ledit isolateur (20)

de support ;

- des bornes (30), reliées aux extrémités dudit interrupteur de courant et

- au moins une bague (40) à effet de couronne, agencée pour entourer, au moins partiellement,

l'une des bornes,

caractérisé en ce que

- ladite bague (40) à effet de couronne est munie d'une couche superficielle hydrophobe

(42).

2. Disjoncteur selon la revendication 1, dans lequel ladite couche superficielle hydrophobe

(42) est faite de l'un quelconque des matériaux parmi un caoutchouc ou une résine,

tel que, par ex., un caoutchouc silicone ou une résine fluorée ou silicone.

3. Disjoncteur selon la revendication 1 ou 2, dans lequel ladite couche superficielle

hydrophobe (42) couvre essentiellement l'intégralité de la surface de ladite bague

à effet de couronne.

4. Disjoncteur selon la revendication 1 ou 2, dans lequel ladite couche superficielle

hydrophobe (42) couvre uniquement des parties de la surface de ladite bague à effet

de couronne, de préférence des parties inférieures de la surface de ladite bague à

effet de couronne.

5. Disjoncteur selon l'une quelconque des revendications 1 à 4, dans lequel la bague

à effet de couronne est ouverte.

6. Disjoncteur selon l'une quelconque des revendications 1 à 5 comprenant une autre bague

à effet de couronne, agencée pour entourer, au moins partiellement, l'une des bornes,

les bagues à effet de couronne étant agencées de manière concentrique l'une par rapport

à l'autre.

7. Disjoncteur selon l'une quelconque des revendications 1 à 6, comprenant une bague

à effet de couronne, agencée pour entourer, au moins partiellement, une autre borne,

les bagues à effet de couronne étant agencées de manière concentrique l'une par rapport

à l'autre.

8. Disjoncteur selon l'une quelconque des revendications 1 à 7, comprenant un autre interrupteur

allongé (10) de courant et des bornes (30), reliées aux extrémités de l'interrupteur

de courant, les interrupteurs de courant étant agencés de manière concentrique l'un

par rapport à l'autre et étant reliés en série, dans lequel l'une des bornes, qui

est entourée, au moins partiellement, par la bague (40) à effet de couronne, est une

borne extérieure desdits interrupteurs de courant, reliés en série et comprenant,

en outre, une bague (40) à effet de couronne, agencée pour entourer, au moins partiellement,

l'autre borne extérieure desdits interrupteurs de courant, reliés en série et étant

munie d'une couche superficielle hydrophobe (42), les bagues à effet de couronne étant

agencées de manière concentrique l'une par rapport à l'autre.

9. Disjoncteur selon l'une quelconque des revendications 1 à 7, dans lequel ledit interrupteur

allongé de courant est agencé essentiellement horizontalement et ladite bague à effet

de couronne est agencée, de sorte que la distance verticale (d1), entre la surface

intérieure de l'extrémité inférieure de ladite bague à effet de couronne et un axe

central (10a) dudit interrupteur allongé (10) de courant, agencé essentiellement horizontalement,

est entre environ 1,5 et environ 4 fois plus courte que la distance (d2) entre la

surface intérieure de l'extrémité supérieure de ladite bague à effet de couronne et

dudit axe central.

10. Disjoncteur selon l'une quelconque des revendications 1 à 7, comprenant un condensateur

allongé (50), agencé essentiellement horizontalement et / ou une résistance (60),

connectée entre les bornes, en parallèle avec l'interrupteur (10) de courant, qui

est agencé essentiellement horizontalement, dans lequel ladite bague (40) à effet

de couronne est agencée, de sorte que la distance verticale (d1), entre la surface

intérieure de l'extrémité inférieure de ladite bague à effet de couronne et un axe

central (10a) dudit interrupteur allongé (10) de courant, agencé essentiellement horizontalement,

dudit condensateur allongé (50), agencé essentiellement horizontalement ou de ladite

résistance allongée (60), agencée essentiellement horizontalement, quelque soit l'élément

qui est situé le plus bas, est entre environ 1,5 et environ 4 fois plus courte que

la distance (d2) entre la surface intérieure de l'extrémité supérieure de ladite bague

à effet de couronne et dudit axe central.

11. Disjoncteur triphasé à réservoir vivant à haute tension selon l'une quelconque des

revendications 1 à 10, comprenant trois disjoncteurs, un pour chaque phase.

12. Procédé, destiné à préparer un disjoncteur à réservoir vivant à haute tension, comprenant

un isolateur (20) de support, au moins un interrupteur allongé (10) de courant, prévu

sur ledit isolateur (20) de support, des bornes (30), connectées aux extrémités dudit

interrupteur de courant et au moins une bague (40) à effet de couronne, agencée pour

entourer, au moins partiellement, l'une des bornes, ledit procédé étant

caractérisé par l'opération, consistant à

- munir ladite au moins une bague (40) à effet de couronne d'une couche superficielle

hydrophobe (42).

13. Procédé selon la revendication 12, dans lequel l'opération de fourniture comprend

l'opération, consistant à pulvériser ou à revêtir ladite au moins une bague à effet

de couronne avec un matériau hydrophobe.

14. Procédé selon la revendication 12 ou 13, dans lequel ladite couche superficielle hydrophobe

(42) est faite d'un matériau quelconque parmi un caoutchouc ou une résine, tel que,

par ex, un caoutchouc silicone ou une résine fluorée ou silicone.

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the reader's convenience only.

It does not form part of the European patent document. Even though great care has

been taken in compiling the references, errors or omissions cannot be excluded and

the EPO disclaims all liability in this regard.

Patent documents cited in the description