|

(11) | EP 2 235 226 B1 |

| (12) | EUROPEAN PATENT SPECIFICATION |

|

|

| (54) |

METHOD FOR SELECTING COMPOSITION OF STEEL AND ITS USE VERFAHREN ZUR WAHL DER ZUSAMMENSETZUNG VON STAHL UND VERWENDUNG DAVON PROCÉDÉ DE SÉLECTION DE LA COMPOSITION DE L'ACIER, ACIER, ET SON UTILISATION |

|

|

|||||||||||||||||||||||||||||||

| Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). |

BACKGROUND OF THE INVENTION

[0001] The invention relates to a method for selecting the composition of low-alloy steel, and for manufacturing a steel product, for applications exposed to high temperatures.

[0002] The invention also relates to a low-alloy hot rolled or normalized steel for use in applications, where endurance to high temperatures and heat resistance is required, the steel having a carbon concentration of above 0.01 percent by weight. This steel may be called fireproof steel and it is preferably hot-rolled.

[0004] A special feature of fireproof structural steel is that its strength at high temperatures caused by fire is higher than conventional structural steels. In conventional structural steels, the strength decreases essentially as temperature rises, because the movement of steel dislocations becomes easier due to increasing thermal activation. The strength of fireproof steel is less sensitive to temperature increases than that of conventional structural steel.

[0005] In conventional fireproof structural steels, the movement of dislocations is made more difficult by alloying the steel with Mo, Cr, V, or Nb, for example, into the steel. These elements react with the carbon in the steel and form M-C clusters or MxCy precipitations, wherein M is Mo or Cr or V or Nb, and x and y are specific to different compounds. M-C clusters cause interactive solid solution hardening that is an effective hardening mechanism in heat-resistant steels. MxCy precipitations may already be in the steel in supply condition or they may be formed during the heating caused by fire.

[0006] Published patent JP2004339549 discloses a fireproof steel with a tensile strength grade of 490 MPa and yield strength grade of 325 MPa. The publication teaches that boron and molybdenum are necessary alloying elements (Mo: 0.1-<0.5%, B: 0.0005-0.003%). In addition, manganese is limited to small concentrations (Mn 0.1-<0.9%), and during manufacturing the cooling rate after rolling is limited to values larger than 0.3 °C/s. The microstructure of steel should contain 20-90% bainite with the rest being ferrite. Fire properties remain good up to 750°C. The publication does not teach how to select fireproof steel with a yield strength of above 355, 420, 460, 500, or 690 MPa and fire properties that remain good up to 800°C.

[0007] Published patent JP2002173733 discloses a fireproof steel that maintains good strength up to 800°C. The invention is based on alloying elements that increase austenite formation temperature (Ac1) up to 800 to 900°C. The publication mentions for instance the following alloying elements and their concentrations: Si 0.2-1.2%, Mn ≤ 0.5%, 0.05% < Al ≤ 1%, Mo 0.4-1.5%, V 0.05-0.2%. The tensile strength grades of the steels are 400 and 490 MPa. The corresponding yield strength grades are 235 and 325 MPa. This publication also does not teach how to manufacture fireproof steel with a yield strength of above 355, 420, 460, 500, or 690 MPa.

[0008] Published patent JP2006241552 discloses a high-strength fireproof steel with a yield strength grade of 440 MPa and tensile strength grade of 590 MPa. The fire-resistance properties are mainly based on high molybdenum concentrations and rather high carbon concentrations: 0.3% ≤ Mo < 0.7%, C 0.04-0.14%. Only a small amount of niobium is used, Nb 0.01-0.05%. According to the teachings of the publication, it is not possible to manufacture fireproof steel with a molybdenum concentration below 0.3%, carbon concentration below 0.04%, or niobium concentration above 0.05%.

[0009] US patent application 2006/0063335 A1 discloses a high-strength fire-resistant low-alloy steel. Its fire-resistant properties are based on a relatively high molybdenum concentration and on the use of boron. The molybdenum concentration is preferably 0.2-1.1 wt % and boron 0.0005-0.003 wt %. Presumably the impact strength of the steel is not especially good, because the alloying of boron weakens it. Molybdenum also weakens the impact strength, and is also an expensive alloying element.

[0010] WO 2006/093282 discloses a low alloy hot-rolled fire resistant steel and a method for manufacturing the same.

[0011] A drawback of the above patent publications is that they do not teach how to select a composition of fireproof steel and to manufacture a steel product to correspond to a desired yield strength grade in the strength range of 355 to 690 MPa and a desired fire-resistant property (by utilizing the strengthening potential of the steel that depends on the composition of the steel).

BRIEF DESCRIPTION OF THE INVENTION

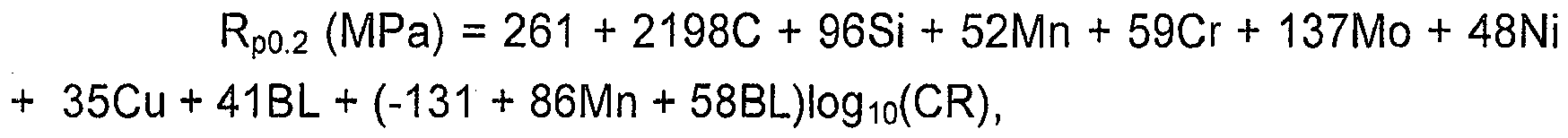

[0012] An object of the invention is to provide a method with which the composition of steel may be selected to correspond to a desired fire-resistance and strength at high temperatures and a method for manufacturing a steel product having said composition. To achieve this, the method of the invention is characterised by

selecting the C, Si, Mn, Cr, Mo, Ni, Cu and B -level and the cooling rate (CR) of the steel after hot-rolling,

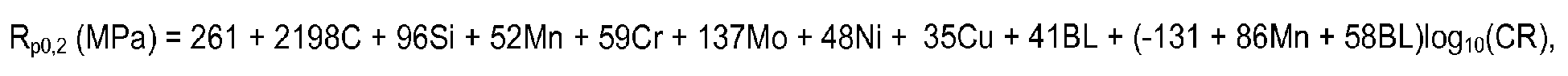

calculating the yield strength of the steel having the selected composition using the formula

C is the carbon concentration of the steel (wt %),

Si is the silicon concentration of the steel (wt %),

Mn is the manganese concentration of the steel (wt %),

Cr is the chromium concentration of the steel (wt %),

Mo is the molybdenum concentration of the steel (wt %),

Ni is the nickel concentration of the steel (wt %),

Cu is the copper concentration of the steel (wt %), and

BL refers to the boron level of the steel, and

BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008, wherein B is the boron concentration of the steel (wt %), and

CR refers to the cooling rate after hot-rolling (°C/s),

comparing the calculated yield strength with a desired yield strength grade specified for the application,

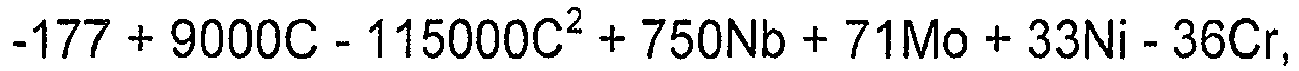

if the calculated yield strength satisfies the desired yield strength grade, calculating for the steel having said composition a strengthening potential, LP95, using the formula

Nb is the niobium concentration of the steel (wt %), and

if the calculated strengthening potential LP95 > 0, the steel having said composition is suitable to be used in the application; and

the method further comprising manufacturing the steel product using the selected composition and the selected cooling rate.

LP95 is the strengthening potential of the steel that provides an estimate on how much the yield strength of the steel (MPa) increases at room temperature, if steel is heated to a temperature of 600°C for one hour. In the stengthening potential formula C is the carbon concentration of the steel (wt %), when the steel is in the hot-rolled condition, and C is the carbon concentration in solution in austenite, Csol, at the normalizing temperature of the steel, when the steel is normalized steel, and

Nb is the niobium concentration of steel (wt %), when the steel is in the hot-rolled condition, and Nb is the niobium concentration in solution in austenite, Nbsol, at the normalizing temperature of the steel, when the steel is normalized steel.

[0013] The correctness of the strengthening potential has been tested to be approximately 95%, i.e., the room-temperature yield point of the steel heated to a temperature of 600 °C for one hour deducted by the yield point of the steel in delivery state will at a probability of 95% increase at least by the value LP95.

[0014] In the invention, it was surprisingly detected that quite small alloying element concentrations produce good fire-resistance, when the alloying elements and their concentrations are selected correctly.

[0015] The value of the strengthening potential LP95 is preferably selected to be above 50, whereby a steel has been selected having a good fire-resistance at high temperatures and a high strength reduction coefficient (the strength does not decrease much at high temperatures).

[0016] It has been noted that niobium greatly increases fire-resistance which is why the niobium concentration of steel is preferably at least 0.04 wt %. Most preferably, the niobium concentration is 0.08-0.12 wt %. During hot-rolling of steel, niobium precipitates into niobium carbides, which results in a smaller grain size of steel, improved ductility and strength. Part of the niobium also precipitates into niobium carbides during the cooling after hot-rolling. However, part of the niobium remains in the solution when the carbon concentration of steel is very low, such as in the steel of the invention; the higher concentration of niobium, the more of it remains in solution. In case of fire, the niobium in solution joins the carbon of the steel and forms strengthening precipitations and clusters. As a result of this, the steel remains strong at temperatures caused by fire.

[0017] Because carbon increases the strengthening potential to a significant extent, the carbon concentration is at least above 0.01 wt % and preferably above 0.03 wt %. The maximum value of the steel strengthening potential is reached at a carbon concentration of below 0.05 wt %, which is why the upper limit for carbon concentration is preferably selected to be 0.05 wt %. Another reason for preferably selecting 0.05% as the upper limit for carbon concentration is that the impact strength and weldability of the steel then remain good.

[0018] Because (surprisingly) the molybdenum concentration of steel does not much increase the strengthening potential of steel, and molybdenum is also an expensive alloying element, the molybdenum concentration is preferably selected to be below 0.4 wt %.

[0019] Preferably the composition of the steel is selected so that its composition in percent by weight is:

| C: | 0.01-0.05 |

| Si: | at most 0.7 |

| Mn: | 1.0-2.3 |

| Ni: | at most 1.5 |

| Cr: | at most 1.5 |

| Mo: | at most 0.7 |

| Cu: | at most 0.3 |

| Nb: | 0.04-0.15 |

| B: | at most 0.004 |

| N: | at most 0.01 |

| Al: | at most 0.1 |

| V: | at most 0.02 |

| Ti: | at most 0.05 |

| Ca: | at most 0.006, whereby |

[0020] The greatest advantages of the method of the invention are that, at a general level, it facilitates the selection of the composition of steel and manufacturing of a steel product, for the purpose of obtaining steel with good fire-resistance properties, whereby the method also makes it possible to minimize alloying element costs. The method also facilitates the selection of the composition for the purpose of obtaining steel classified in various strength grades S355, S420, S460, S500, and S690 (the minimum values of yield strengths 355, 420, 460, 500, and 690 MPa). The steel is preferably a hot-rolled plate or strip, even though other delivery forms may also apply.

[0021] Another object of the invention is to provide for use a fire-resistant low-alloy steel with good fire-resistance without needing to use high concentrations of expensive alloying elements in it. The steel is also easy to manufacture and weld.

[0022] To achieve this, the steel is mainly characterised in that its composition in percentage by weight is as follows:

| C: | above 0.01 and at most 0.05 |

| Si: | at most 0.7 |

| Mn: | 1.0-2.3 |

| Ni: | at most 1.5 |

| Cr: | at most 1.5 |

| Mo: | < 0.4 |

| Cu: | at most 0.3 |

| Nb: | 0.04-0.15 |

| B: | at most 0.004 |

| N: | at most 0.01 |

| Al: | at most 0.1 |

| V: | at most 0.02 |

| Ti: | at most 0.05 |

| Ca: | at most 0.006, whereby |

Mn > 1.6 or Mo < 0.1, if B > 0.0005, and

the alloying level of the steel ST = 33.8C + 0.98Si + 1.15Mn + 0.47Cr + 2.32Mo + 0.85Ni

+ 0.47Cu + 1.16BL = 3.0-8.0, wherein BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008,

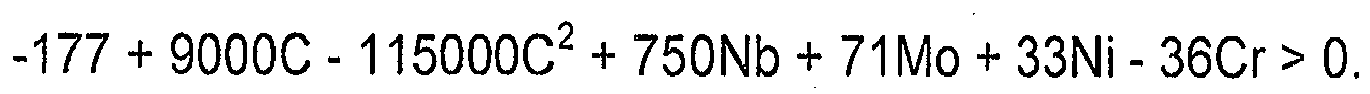

and the composition of the steel meets the criterion

[0023] Preferably -177 + 9000C - 115000C2 + 750Nb + 71 Mo + 33Ni - 36Cr > 50, whereby the fire resistance of the steel at high temperatures is especially good and the strength reduction coefficient is high (the strength does not decrease much at high temperatures).

[0024] Preferably, the lower limit of the carbon concentration of the steel is 0.03 wt %, because carbon increases the strengthening potential significantly.

[0025] When the upper limit of the carbon concentration of the steel is 0.05 wt %, the weldability of the steel still remains good regardless of the carbon equivalent.

[0027] If the boron concentration of the steel is above 0.0005 wt %, it is advantageous for the impact strength of the steel that at the same time the manganese concentration is above 1.6 wt % and the molybdenum concentration is below 0.1 wt %.

[0028] The molybdenum concentration of the steel is preferably below 0.4 wt %, even though the boron concentration of the steel ≤ 0.0005 wt %.

[0031] Surprisingly, the reduction coefficient of the low-alloy steel of the invention at 700°C is significantly higher than the reduction coefficient presented in SFS standard EN 1993-1-2. Preferably, the reduction coefficient achievable for the steel is above 0.3 and more preferably above 0.4 at 700°C as measured using a transient test.

[0032] Preferred embodiments of the steel according to the invention are disclosed in the attached claims 3 to 13.

[0033] The greatest advantages of the steel according to the invention are that its fire resistance is good and the fire resistance is achieved with a small amount of expensive alloying elements. In addition, the steel can be easily and economically manufactured for yield strength grades 355, 420, 460, 500, and 690 MPa, and its composition is suitable for both thick and thin forms. The steel is preferably a hot-rolled plate or strip, even though other products or forms may also apply.

[0034] The steel according to the invention is used in applications requiring high strength at temperatures above 400°C, even 600 to 800°C. Such applications include those in which the steel must be fire resistant. These typically include steel structures of buildings wherein the steel is preferably used in building beams and lattice structures. The building beams may for instance be welded double-web Q beams or single-web I beams, in which steel is used in the entire beam or only in parts significant for fire protection, such as the top or bottom flange. The steel of the invention works especially well for instance in situations where the intermediate floor slab system of a building is supported by a Q beam and the bottom or top flange of the beam is not protected by the slab system or concreting, whereby the flange requires especially good fire resistance. Other fire protection means are not needed when the required part of the beam is made of the steel of the invention.

[0035] By using the steel of the invention in structures, it is possible to leave out traditional fire protection means, such as painting steel structures (wherein the paint is of a type that foams at high temperatures and therefore provides heat insulation), protecting steel structures by encasing them with gypsum boards or protecting them with rigid, heat-resistant, insulating wool.

[0036] In the steel of the invention, molybdenum and boron are not necessary, even though they may be utilised (Mo: 0-0.7 wt %, preferably < 0.4 wt %, B: 0-0.0040 wt %). Manganese is an essential alloying element to provide strength and impact strength, which is why manganese is alloyed in 1-2.3 wt % depending on the boron concentration of the steel. It has been noted that in hot-rolled steel both molybdenum and boron reduce the impact strength of the steel, whereas by increasing the manganese concentration, the impact strength of the steels according to the invention improves. The effect of boron is great: the transition temperature of impact strength may increase as much as 50°C when boron is alloyed in steel. However, if the cost-effectiveness of boron as an alloying element is to be utilised by alloying above 0.0005 wt % of boron into the steel, the manganese concentration is selected to be above 1.6 wt % and/or (preferably and than or) the molybdenum concentration at most 0.1 wt%.

[0037] In the steel of the invention, the proportions of bainite and ferrite in the microstructure are not restricted.

[0038] The invention makes it possible to design steel structures with desired fire-resistance properties at manufacturing costs that are as economical as possible.

BRIEF DESCRIPTION OF FIGURES

[0039] The invention will now be described in greater detail by means of examples and with reference to the attached figure.

DETAILED DESCRIPTION OF THE INVENTION

[0040] When the intention is to obtain a fireproof steel meeting certain tensile properties, a steel is selected according to the invention by using the formula

wherein LP95 is the strengthening potential of the steel that provides an estimate on how much the yield strength of the steel increases (MPa) at room temperature, if it is heated to a temperature of 600°C for one hour,

C is the carbon concentration of the steel (wt %) when the steel is in the hot-rolled condition, and C is the carbon concentration in a solution in austenite, Csol, at the normalizing temperature of the steel, when the steel is normalized steel,

Nb is the niobium concentration of the steel (wt %), when the steel is in the hot-rolled condition, and Nb is the niobium concentration in solution in austenite, Nbsol, at the normalizing temperature of the steel, when the steel is normalized steel,

Mo is the molybdenum concentration of the steel (wt %),

Ni is the nickel concentration of the steel (wt %), and

Cr is the chromium concentration of the steel (wt %).

[0041] The correctness of the formula has been tested to be approximately 95%, i.e., the room-temperature yield point of the steel heated to a temperature of 600 °C for one hour deducted by the yield point of the steel in delivery state will at a probability of 95% increase at least by the value LP95.

[0042] Preferably, LP95 > 50, and in applications requiring very high fire resistance, LP95 > 100 is selected.

[0043] The effect of carbon on the strengthening potential is great, and this may also be observed from the attached figure that shows steel that contains not only carbon, but also 0.04 wt % of Nb, 0.14 wt % of Cr, 0.17 wt % of Mo, and 0.76 wt % of Ni. The LP50 marked in the curve refers to the strengthening potential that will be exceeded at 50% probability (LP50=LP95+55).

[0044] The carbon concentration of the steel is at least 0.01 wt %. Preferably, the carbon concentration of the steel is above 0.03 wt % and at most 0.05 wt %, and its niobium concentration is 0.04-0.15 wt % and more preferably 0.08-0.12 wt %. The aim is to keep the molybdenum concentration relatively low due to the high price of molybdenum. The molybdenum concentration is preferably below 0.4 wt %, and if the steel contains above 0.0005 wt % of boron, the molybdenum concentration is below 0.1 wt %.

[0045] The above formula and condition for the strengthening potential LP95 applies when the following conditions are met:

- 1) the steel is manufactured hot-rolled either in a plate or strip mill,

- 2) the heating temperature of a blank, TS, is higher than NBDT, i.e., niobium dissolution temperature (dissolution temperature

of niobium carbonitrides), but at most 1300°C; it is even more preferable that the

heating temperature of a blank, TS, is higher than NBDT by +50°C.

NBDT is calculated using the Dong formula:

- 3) the finish rolling temperature FRT is higher than the formation temperature of ferrite, Ar3, and at most 1050°C.

[0047] Cooling after plate-rolling may take place freely in air or as accelerated cooling with water, for instance, as long as the cooling time from 750°C to 400°C is shorter than 5000 s which corresponds to the average cooling rate that is higher than 0.07°C/s at 750 to 400°C.

[0048] After strip-rolling, the cooling must be accelerated with water to a temperature of 450°C or below.

[0049] If heating temperatures of a blank, TS, below NBDT are used to obtain good impact strength, for instance, the same LP95 formula is used to calculate the strengthening potential, but the carbon and niobium concentrations refer to those in solution in austenite at the heating temperature of a blank, Csol and Nbsol, that is,

and

and

wherein

T1=TS, the heating temperature of a blank in Celsius.

[0050] If normalizing is performed after rolling, the LP95 formula may still be used as long as the normalizing temperature, Tn, exceeds NBDT. If Tn < NBDT, the LP95 formula uses carbon and niobium concentrations, Csol and Nbsol, that are at the normalization temperature in the solution. Csol and Nbsol are calculated using the above Dong formula by placing T1=Tn into the formula.

[0052] Table 2 shows compositions of steel plates according to the invention within the alloying element concentrations given in Table 1. Yield point and tensile strength values were measured for these steel plates, see Table 3.

Table 2: Chemical compositions of plates (wt %)

| Plate | Thickness mm | Type | C % | Si % | Mn % | Cu % | Cr % | Ni % | Mo % | Nb % | B % | BL | ST |

| 1142-1 / -2 | 12 | miniature | 0.024 | 0.17 | 1.99 | 0.22 | 0.03 | 0.82 | 0.26 | 0.054 | 0.0003 | 0 | 4.7 |

| 1143-1 / -2 | 12 | miniature | 0.043 | 0.18 | 1.99 | 0.23 | 0.03 | 0.81 | 0.26 | 0.054 | 0.0003 | 0 | 5.3 |

| 1144-1 / -2 | 12 | miniature | 0.011 | 0.19 | 1.98 | 0.22 | 0.03 | 0.82 | 0.26 | 0.052 | 0.0003 | 0 | 4.3 |

| 1145-1 / -2 | 12 | miniature | 0.040 | 0.18 | 2.08 | 0.21 | 0.03 | 0.13 | 0.11 | 0.103 | 0.0013 | 1 | 5.6 |

| 1146-1 / -2 | 12 | miniature | 0.022 | 0.17 | 2.09 | 0.22 | 0.03 | 1.01 | 0.11 | 0.048 | 0.0004 | 0 | 4.6 |

| 1147-1 / -2 | 12 | miniature | 0.015 | 0.18 | 1.36 | 0.22 | 0.03 | 0.13 | 0.61 | 0.044 | 0.0017 | 1 | 5.1 |

| 1148-1 / -2 | 12 | miniature | 0.040 | 0.18 | 1.33 | 0.22 | 0.03 | 1.02 | 0.61 | 0.112 | 0.0004 | 0 | 5.5 |

| 1149-1 / -2 | 12 | miniature | 0.016 | 0.19 | 2.08 | 0.22 | 0.99 | 0.13 | 0.60 | 0.101 | 0.0004 | 0 | 5.2 |

| 1150-1 / -2 | 12 | miniature | 0.015 | 0.17 | 1.35 | 0.21 | 0.99 | 1.02 | 0.11 | 0.100 | 0.0011 | 1 | 5.1 |

| 1151-1 / -2 | 12 | miniature | 0.041 | 0.19 | 1.36 | 0.22 | 1.00 | 0.13 | 0.11 | 0.048 | 0.0003 | 0 | 4.1 |

| 1152-1 / -2 | 12 | miniature | 0.040 | 0.20 | 2.09 | 0.23 | 1.00 | 1.00 | 0.61 | 0.046 | 0.0014 | 1 | 8.0 |

| 1180-1 / -2 | 12 | miniature | 0.029 | 0.19 | 1.60 | 0.21 | 0.03 | 0.02 | 0.00 | 0.042 | 0.0003 | 0 | 3.1 |

| 1181-1 / -2 | 12 | miniature | 0.028 | 0.68 | 1.91 | 0.22 | 0.03 | 0.80 | 0.24 | 0.048 | 0.0003 | 0 | 5.2 |

| 1182-1 / -2 | 12 | miniature | 0.036 | 0.21 | 2.43 | 0.22 | 0.82 | 0.32 | 0.00 | 0.043 | 0.0027 | 1 | 6.1 |

| 1183-1 / -2 | 12 | miniature | 0.047 | 0.23 | 2.02 | 0.22 | 0.91 | 0.99 | 0.48 | 0.062 | 0.0003 | 0 | 6.6 |

| 1184-1 / -2 | 12 | miniature | 0.037 | 0.22 | 2.02 | 0.23 | 0.91 | 0.51 | 0.10 | 0.097 | 0.0030 | 1 | 6.2 |

| 68816-023 | 120 | normal | 0.014 | 0.29 | 1.92 | 0.22 | 0.16 | 0.77 | 0.19 | 0.050 | 0.0001 | 0 | 4.3 |

| 74705-031 | 20 | normal | 0.016 | 0.26 | 2.13 | 0.20 | 0.18 | 0.78 | 0.20 | 0.049 | 0.0003 | 0 | 4.5 |

| 15874-016 | 12 | normal | 0.017 | 0.30 | 1.93 | 0.21 | 0.14 | 0.76 | 0.17 | 0.042 | 0.0003 | 0 | 4.3 |

| 15874-033 | 20 | normal | 0.017 | 0.30 | 1.93 | 0.21 | 0.14 | 0.76 | 0.17 | 0.042 | 0.0003 | 0 | 4.3 |

[0054] The yield point, Rp0.2 (MPa), and tensile strength, Rm (MPa), of the steel according to the invention after hot-rolling and cooling may be predicted using the chemical composition and cooling rate of the steel with formulas

[0055] In the above formulas, C, Si, Mn, Cr, Mo, and Cu refer to the alloying element concentrations in percent by weight. C is the carbon concentration of the steel (wt %), when the steel is hot-rolled steel, and C is the carbon concentration in solution in austenite, Csol, at the normalization temperature of the steel, when the steel is normalized steel. BL refers to the boron level. If B ≤ 0.0005%, BL = 0; if B > 0.0008% BL = 1. (B concentrations of 0.0006 ... 0.0008% are not recommended, because the activity of boron is then uncertain.) CR refers to the average cooling rate at 750 to 400°C.

[0056] The above formula predicting the yield strength is used when it is necessary to select steel that corresponds to a desired yield strength grade.

[0057] The percentage elongation after fracture, A, measured with a proportional gauge length, which is 5.65 x (sample cross-sectional area)0.5, may be calculated using the formula

[0058] If the plate is made air-cooled, the cooling rate may be estimated on the basis of the thickness of the plate by using the following formula:

wherein

T0 is a first temperature on Kelvin scale (in this case 750 + 273 K),

T1 is a second temperature on Kelvin scale (in this case 400 + 273 K), and

t is the thickness of the plate in millimetres.

[0059] The correctness of the presented strengthening potential has been verified with both miniature plates and normal-size plates whose chemical compositions were according to Table 1 and manufacturing parameters within the above-mentioned limits. In this context, reference is made to Table 3 that shows the yield and tensile strengths of the plates after hot-rolling and cooling as well as their computational/predicted strengths. The miniature plates were made with a pilot roll to be 12 mm thick. After rolling, the miniature plates were cooled either freely in air or using accelerated cooling with water to room temperature as soon as possible after rolling. This way, cooling rates of 13 or 1.5°C/s were achieved at 750 to 400°C. Normal-size plates were 12 to 120 mm thick. They were rolled within the above-mentioned parameter limits. After rolling they were cooled either freely in air or using accelerated cooling with water to a temperature of 100 to 300°C. Table 3 shows that the predicted values are close to the measured values in both miniature and normal-size plates.

[0060] Table 3 also proves that by selecting the composition and manufacturing parameters of the steel by using the limits and formulas of the invention, it is possible to manufacture plates for yield strength grades 420, 460, 500, or 690 MPa, for instance. The impact strength of the steel is also adjusted to the desired level by controlling the impurities contents (S, P, O, N), calcium processing, and rolling and cooling conditions.

Table 3: Yield and tensile strengths of the plates after hot-rolling and cooling (AR

= as rolled)

| Plate | Thickness mm | CR °C/s | Rp0.2(AR) measured | Rp0.2(AR) predicted | Rm(AR) measured | Rm(AR) predicted | Strength grade MPa |

| 1142-1 | 12 | 13.0 | 544 | 563 | 703 | 707 | 500 |

| 1143-1 | 12 | 13.0 | 555 | 606 | 764 | 801 | 500 |

| 1144-1 | 12 | 13.0 | 525 | 535 | 642 | 644 | 500 |

| 1145-1 | 12 | 13.0 | 619 | 665 | 829 | 835 | 500 |

| 1146-1 | 12 | 13.0 | 525 | 562 | 687 | 706 | 500 |

| 1147-1 | 12 | 13.0 | 579 | 573 | 721 | 693 | 500 |

| 1148-1 | 12 | 13.0 | 590 | 559 | 779 | 771 | 500 |

| 1149-1 | 12 | 13.0 | 607 | 631 | 748 | 755 | 500 |

| 1150-1 | 12 | 13.0 | 585 | 601 | 752 | 795 | 500 |

| 1151-1 | 12 | 13.0 | 493 | 512 | 715 | 735 | 460 |

| 1152-1 | 12 | 13.0 | 809 | 836 | 1082 | 1068 | 690 |

| 1180-1 | 12 | 13.0 | 498 | 444 | 624 | 588 | 460 |

| 1181-1 | 12 | 13.0 | 581 | 606 | 760 | 763 | 500 |

| 1182-1 | 12 | 13.0 | 819 | 752 | 980 | 936 | 690 |

| 1183-1 | 12 | 13.0 | 816 | 714 | 1001 | 954 | 690 |

| 1184-1 | 12 | 13.0 | 771 | 723 | 982 | 933 | 690 |

| 1142-2 | 12 | 1.5 | 509 | 525 | 680 | 680 | 500 |

| 1143-2 | 12 | 1.5 | 532 | 568 | 740 | 749 | 500 |

| 1144-2 | 12 | 1.5 | 511 | 497 | 633 | 633 | 500 |

| 1145-2 | 12 | 1.5 | 563 | 565 | 780 | 773 | 500 |

| 1146-2 | 12 | 1.5 | 502 | 516 | 660 | 668 | 500 |

| 1147-2 | 12 | 1.5 | 549 | 531 | 692 | 709 | 500 |

| 1148-2 | 12 | 1.5 | 601 | 574 | 773 | 755 | 500 |

| 1149-2 | 12 | 1.5 | 599 | 585 | 751 | 730 | 500 |

| 1150-2 | 12 | 1.5 | 560 | 559 | 732 | 727 | 500 |

| 1151-2 | 12 | 1.5 | 446 | 525 | 644 | 633 | 420 |

| 1152-2 | 12 | 1.5 | 679 | 735 | 974 | 1012 | 500 |

| 1180-2 | 12 | 1.5 | 480 | 438 | 535 | 531 | 460 |

| 1181-2 | 12 | 1.5 | 585 | 574 | 732 | 729 | 500 |

| 1182-2 | 12 | 1.5 | 630 | 623 | 830 | 838 | 500 |

| 1183-2 | 12 | 1.5 | 730 | 673 | 897 | 882 | 690 |

| 1184-2 | 12 | 1.5 | 665 | 627 | 851 | 839 | 500 |

| 74705-031 | 20 | 12.0 | 569 | 571 | 660 | 693 | 500 |

| 15874-016 | 12 | 25.0 | 569 | 552 | 656 | 682 | 500 |

| 15874-033 | 20 | 11.0 | 571 | 539 | 644 | 670 | 500 |

| 68816-023 | 120 | 0.07 | 467 | 460 | 573 | 599 | 460 |

[0061] Tables 2 and 3 show that the cooling rate does not much affect the strength properties of the plates at least when the cooling rates are low, so it is easy to use the presented strengthening potential formula to design compositions for fireproof steels in such a manner that it is possible to use the same composition to manufacture both thick and thin plates and strip plates. The examples of Table 3 show that a given strength grade may be manufactured of the same composition regardless of the cooling rate.

[0062] Table 4 shows calculated strengthening potentials LP50 and LP95 and measured strength increases. It can be noted that in only two cases of thirty three the measured strengthening potential is lower than the LP95 prediction. The highest predicted LP95 value is 161 MPa that is achieved with the relatively high-alloy plate 1148.

Table 4: Calculated LP values in comparison with measured differences Rp0.2(1 h600°C)-Rp0.2(AR)

| Plate | Thickness | CR | Rp0.2(AR) measured | Rp0.2(1h600°C) measured | Rm(1h600°C) measured | Rp0.2(1h°600C)-Rp0.2(AR) measured | LP50 | LP95 |

| mm | °C/s | MPa | MPa | MPa | MPa | MPa | MPa | |

| 1142-1 | 12 | 13.0 | 544 | 677 | 735 | 133 | 114 | 59 |

| 1143-1 | 12 | 13.0 | 555 | 722 | 783 | 167 | 139 | 84 |

| 1144-1 | 12 | 13.0 | 525 | 545 | 620 | 20 | 47 | -8 |

| 1145-1 | 12 | 13.0 | 619 | 792 | 847 | 173 | 144 | 89 |

| 1146-1 | 12 | 13.0 | 525 | 647 | 703 | 122 | 98 | 43 |

| 1147-1 | 12 | 13.0 | 579 | 661 | 755 | 82 | 67 | 13 |

| 1148-1 | 12 | 13.0 | 590 | 801 | 868 | 211 | 216 | 161 |

| 1149-1 | 12 | 13.0 | 607 | 683 | 754 | 76 | 80 | 25 |

| 1150-1 | 12 | 13.0 | 585 | 675 | 743 | 90 | 69 | 14 |

| 1151-1 | 12 | 13.0 | 493 | 626 | 704 | 133 | 67 | 12 |

| 1152-1 | 12 | 13.0 | 809 | 970 | 1011 | 161 | 131 | 76 |

| 1180-1 | 12 | 13.0 | 498 | 572 | 628 | 74 | 75 | 20 |

| 1181-1 | 12 | 13.0 | 581 | 704 | 782 | 123 | 120 | 65 |

| 1182-1 | 12 | 13.0 | 819 | 823 | 863 | 4 | 68 | 13 |

| 1183-1 | 12 | 13.0 | 816 | 954 | 1006 | 138 | 130 | 75 |

| 1184-1 | 12 | 13.0 | 771 | 872 | 932 | 101 | 119 | 64 |

| 1142-2 | 12 | 1.5 | 509 | 648 | 736 | 139 | 114 | 59 |

| 1143-2 | 12 | 1.5 | 532 | 678 | 786 | 146 | 139 | 84 |

| 1144-2 | 12 | 1.5 | 511 | 527 | 608 | 16 | 47 | -8 |

| 1145-2 | 12 | 1.5 | 563 | 734 | 842 | 171 | 144 | 89 |

| 1146-2 | 12 | 1.5 | 502 | 619 | 703 | 117 | 98 | 43 |

| 1147-2 | 12 | 1.5 | 549 | 639 | 739 | 90 | 67 | 13 |

| 1148-2 | 12 | 1.5 | 601 | 780 | 867 | 179 | 216 | 161 |

| 1149-2 | 12 | 1.5 | 599 | 664 | 731 | 65 | 80 | 25 |

| 1150-2 | 12 | 1.5 | 560 | 651 | 724 | 91 | 69 | 14 |

| 1151-2 | 12 | 1.5 | 446 | 531 | 623 | 85 | 67 | 12 |

| 1152-2 | 12 | 1.5 | 679 | 805 | 965 | 126 | 131 | 76 |

| 1180-2 | 12 | 1.5 | 480 | 488 | 544 | 8 | 75 | 20 |

| 1181-2 | 12 | 1.5 | 585 | 675 | 773 | 90 | 120 | 65 |

| 1182-2 | 12 | 1.5 | 630 | 688 | 792 | 58 | 68 | 13 |

| 1183-2 | 12 | 1.5 | 730 | 807 | 937 | 77 | 130 | 75 |

| 1184-2 | 12 | 1.5 | 665 | 766 | 884 | 101 | 119 | 64 |

| 74705-031 | 20 | 12.0 | 569 | 613 | 670 | 44 | 63 | 8 |

| 15874-016 | 12 | 25.0 | 569 | 591 | 652 | 22 | 63 | 8 |

| 15874-033 | 20 | 11.0 | 571 | 589 | 648 | 18 | 63 | 8 |

| 68816-023 | 120 | 0.1 | 467 | 484 | 574 | 17 | 53 | -2 |

[0063] Table 5 shows the chemical composition of three comparison steels.

Table 5: The chemical composition of three comparison materials (wt %)

| Plate | Thickness mm | CR °C/s | C % | Si % | Mn % | Al % | Nb % | V % | Ti % | Cr % | Cu % | Ni % | Mo % | N % | B % |

| 41278-024 | 30 | 0.3 | 0.12 | 0.35 | 1.56 | 0.040 | 0.037 | 0.004 | 0.005 | 0.02 | 0.01 | 0.04 | 0.00 | 0.0068 | 0.0002 |

| 50902-013 | 20 | 0.4 | 0.14 | 0.36 | 1.50 | 0.042 | 0.040 | 0.039 | 0.017 | 0.02 | 0.01 | 0.48 | 0.00 | 0.0099 | 0.0003 |

| 14630-034 | 20 | 16 | 0.08 | 0.16 | 1.51 | 0.035 | 0.037 | 0.005 | 0.017 | 0.02 | 0.28 | 0.76 | 0.00 | 0.0060 | 0.0003 |

[0064] Plates 41278-024 and 50902-013 were cooled freely in air. Plate 14630-034 was cooled accelerated at 750-550°C.

[0065] Table 6 shows the mechanical properties of comparison steels rolled and after heat treatment. The table shows that the measured strengthening potentials, ReH(AR) - ReH(1h600°C) that correspond to the LP50 value, are typically negative. The comparison steels have clearly higher carbon concentrations than the steels of the invention, and on the basis of the LP95 formula, it is expected that EP decreases when the carbon concentration increases above approximately 0.040%.

Table 6: The mechanical properties of comparison materials rolled and after heat treatment

| Plate | Thick | CR | Rolled | Heat treated 600°C | ReH(600°C)-ReH(AR) | ||||||

| mm | °C/s | ReH MPa | Rm MPa | A5 % | Temp °C | Time min | ReH MPa | Rm MPa | A5 % | MPa | |

| 41278-024 | 30 | 0.3 | 455 | 557 | 30 | 600 | 60 | 445 | 553 | 32 | -10 |

| 50902-013 | 20 | 0.4 | 503 | 642 | 24 | 600 | 40 | 501 | 623 | 24 | -2 |

| 14630-034 | 20 | 16 | 577 | 685 | 14 | 600 | 40 | 572 | 657 | 21 | -5 |

[0066] The fire-resistance of the plates of the invention was tested in transient tests. Their mechanical properties in delivery state are shown in Table 7.

Table 7: The mechanical properties of plates tested in transient tests

| Plate No. | Thickness | Cooling rate | As rolled | Heat-treated 1h600°C | Charpy V as rolled crosswise, -60 °C | ||||

| Rp0.2 | Rm | A | Rp0.2 | Rm | A | ||||

| mm | °C/s | MPa | MPa | % | MPa | MPa | % | J | |

| 74705-031 | 20 | 12 | 569 | 660 | 22 | 613 | 670 | 23 | 310 |

| 15874-016 | 12 | 25 | 569 | 656 | 21 | 591 | 652 | 22 | 207 |

| 15874-033 | 20 | 11 | 571 | 644 | 21 | 589 | 648 | 23 | 271 |

[0067] Table 8 shows the strength properties measured by transient tests at high temperatures for the steel plates of the invention and conventional structural steels. In transient tests, the strength of the material (steel) is measured in hot tensile tests, wherein a piece of steel is loaded in a test furnace at different tensile loads by increasing the temperature from 20°C to 900°C at the same time. Yield strength values at different temperatures are measured for the material (steel) on the basis of the load tests. Yield strength is the level of stress at a selected elongation value. The fire resistance of the plates made according to the invention has been tested in transient tests according to the standard EN 10002-5. A transient test is suitable when there is a need to define the strength properties of the material in fire conditions.

[0068] Table 8 shows the reduction coefficients (ky,e) of yield points of steels at high temperatures.

wherein

fy is an effective yield point at a total elongation of 2%.

[0069] Table 8 shows that the fire properties of the steel plates of the invention are clearly better than those of conventional structural steels: at 700°C, the reduction coefficient of the effective yield point is 82 to 90% higher in the steel of the invention than in conventional steel. The reduction coefficient of the steels of the invention is above 0.3 and preferably above 0.4 at 700°C, which values can be seen to be true, see Table 8.

Table 8: Strength properties measured by transient tests at high temperatures

| Plate of the invention | Temperature | Measured reduction coefficient | Reduction coefficient SFS EN 1993-1-2 | Ratio |

| °C | ky,θ(measured) | ky,θ(EN 1993-1-2) | ky,θ(measured) / ky,θ(EN 1993-1-2) | |

| 74705-031 | 20 | 1.000 | 1.000 | 1.00 |

| 400 | 1.000 | 1.000 | 1.00 | |

| 500 | 0.872 | 0.780 | 1.12 | |

| 600 | 0.655 | 0.470 | 1.39 | |

| 700 | 0.419 | 0.230 | 1.82 | |

| 800 | 0.140 | 0.110 | 1.27 | |

| 900 | 0.061 | 0.060 | 1.02 | |

| 15874-016 | 20 | 1.000 | 1.000 | 1.00 |

| 400 | 1.000 | 1.000 | 1.00 | |

| 500 | 0.932 | 0.780 | 1.20 | |

| 600 | 0.670 | 0.470 | 1.42 | |

| 700 | 0.438 | 0.230 | 1.90 | |

| 800 | 0.152 | 0.110 | 1.38 | |

| 900 | 0.064 | 0.060 | 1.07 |

[0070] Table 9 shows composition information of normalized plates and the niobium dissolution temperature NBDT, and Table 10 shows mechanical properties and strengthening potentials LP50 and LP95 of normalized plates. Plates 15874-016 and 15874-033 were normalized at 950°C that is very close to the dissolution temperature of niobium (NBDT) calculated according to the Dong formula 957°C. In practice, this leads to Csol and Nbsol being very close to the total carbon and niobium concentrations of the plates. The calculated LP values (LP50 = 58 MPa and LP95 = 3 MPa) are well in concordance with the measured strengthening potentials (75 and 69 MPa), so the strengthening potential formulas of the invention may also be used to make normalized fireproof steel. The examples of Tables 9 and 10 show that by using the above formulas and normalization heat-treatment, it is also possible to manufacture fireproof steels in the yield strength grade of 355 MPa.

Table 9: Composition information of normalized plates and dissolution temperature

of niobium NBDT

| Plate | Thickness mm | Normalizing temperature | Ti | N | N* | NBDT | Csol | Nbsol |

| °C | ppm | ppm | ppm | °C | % | % | ||

| 15874-016 | 12 | 950 | 160 | 55 | 8 | 957 | 0.016 | 0.042 |

| 15874-033 | 20 | 950 | 160 | 55 | 8 | 957 | 0.016 | 0.042 |

[0071] Other alloying element concentrations are given in Tables 1 and 2. N* = N - Ti/3.42

Table 10: Mechanical properties and precipitation potentials of normalized plates

(as-rolled mean)

| Plate No. | Thickness | NBDT | As rolled | Heat-treated 1h600°C | Measured strengthening potential Rp0.2(1h600°C)-Rp0.2(AR) | Calculated | |||||

| mm | °C | Rp0.2 | Rm | A | Rp0.2 | Rm | A | LP50 | LP95 | ||

| MPa | MPa | % | MPa | MPa | % | MPa | MPa | MPa | |||

| 15874-016 | 12 | 952 | 383 | 544 | 29 | 458 | 548 | 29 | 75 | 58 | 3 |

| 15874-033 | 20 | 952 | 398 | 554 | 28 | 467 | 561 | 29 | 69 | 58 | 3 |

1. A method for manufacturing a steel product, the method comprising selecting a low-alloy

hot-rolled or normalized steel for applications exposed to high temperatures, characterised by

selecting the C, Si, Mn, Cr, Mo, Ni, Cu and B -level and the cooling rate (CR) of the steel after hot-rolling,

calculating the yield strength of the steel having the selected composition using the formula

wherein

C is the carbon concentration of the steel (wt %),

Si is the silicon concentration of the steel (wt %),

Mn is the manganese concentration of the steel (wt %),

Cr is the chromium concentration of the steel (wt %),

Mo is the molybdenum concentration of the steel (wt %),

Ni is the nickel concentration of the steel (wt %),

Cu is the copper concentration of the steel (wt %), and

BL refers to the boron level of the steel, and

BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008, wherein B is the boron concentration of the steel (wt %), and

CR refers to the cooling rate after hot-rolling (°C/s),

comparing the calculated yield strength with a desired yield strength grade specified for the application,

if the calculated yield strength satisfies the desired yield strength grade, calculating for the steel having said composition a strengthening potential, LP95, using the formula

wherein Nb is the niobium concentration of the steel (wt %), and

if the calculated strengthening potential LP95 > 0, the steel having said composition is suitable to be used in the application; and

the method further comprising manufacturing the steel product using the selected composition and the selected cooling rate.

selecting the C, Si, Mn, Cr, Mo, Ni, Cu and B -level and the cooling rate (CR) of the steel after hot-rolling,

calculating the yield strength of the steel having the selected composition using the formula

wherein

C is the carbon concentration of the steel (wt %),

Si is the silicon concentration of the steel (wt %),

Mn is the manganese concentration of the steel (wt %),

Cr is the chromium concentration of the steel (wt %),

Mo is the molybdenum concentration of the steel (wt %),

Ni is the nickel concentration of the steel (wt %),

Cu is the copper concentration of the steel (wt %), and

BL refers to the boron level of the steel, and

BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008, wherein B is the boron concentration of the steel (wt %), and

CR refers to the cooling rate after hot-rolling (°C/s),

comparing the calculated yield strength with a desired yield strength grade specified for the application,

if the calculated yield strength satisfies the desired yield strength grade, calculating for the steel having said composition a strengthening potential, LP95, using the formula

wherein Nb is the niobium concentration of the steel (wt %), and

if the calculated strengthening potential LP95 > 0, the steel having said composition is suitable to be used in the application; and

the method further comprising manufacturing the steel product using the selected composition and the selected cooling rate.

2. A method as claimed in claim 1, characterised in that the composition of the steel is selected so that its composition in percent by weight

is:

the concentrations of manganese and molybdenum are selected so that Mn > 1.6 or Mo

< 0.1, if B > 0.0005, and

the alloying level of the steel ST = 33.8C + 0.98Si + 1.15Mn + 0.47Cr + 2.32Mo + 0.85Ni + 0.47Cu + 1.16BL so that its value is 3.0-8.0, wherein BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008.

| C: | 0.01-0.05 |

| Si: | at most 0.7 |

| Mn: | 1.0-2.3 |

| Ni: | at most 1.5 |

| Cr: | at most 1.5 |

| Mo: | at most 0.7 |

| Cu: | at most 0.3 |

| Nb: | 0.04-0.15 |

| B: | at most 0.004 |

| N: | at most 0.01 |

| Al: | at most 0.1 |

| V: | at most 0.02 |

| Ti: | at most 0.05 |

| Ca: | at most 0.006, whereby |

the alloying level of the steel ST = 33.8C + 0.98Si + 1.15Mn + 0.47Cr + 2.32Mo + 0.85Ni + 0.47Cu + 1.16BL so that its value is 3.0-8.0, wherein BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008.

3. A low-alloy hot-rolled or normalized steel for use in applications requiring endurance

of high temperatures and heat resistance, the carbon concentration of the steel being

> 0.01 wt %, characterised in that the composition of the steel in percent by weight is as follows:

Mn > 1.6 or Mo < 0.1, if B > 0.0005, and

the alloying level of the steel ST = 33.8C + 0.98Si + 1.15Mn + 0.47Cr + 2.32Mo + 0.85Ni + 0.47Cu + 1.16BL = 3.0 - 8.0, wherein BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008, and the composition of the steel meets the criterion

| C: | above 0.01 and at most 0.05 |

| Si: | at most 0.7 |

| Mn: | 1.0-2.3 |

| Ni: | at most 1.5 |

| Cr: | at most 1.5 |

| Mo: | < 0.4 |

| Cu: | at most 0.3 |

| Nb: | 0.04-0.15 |

| B: | at most 0.004 |

| N: | at most 0.01 |

| Al: | at most 0.1 |

| V: | at most 0.02 |

| Ti: | at most 0.05 |

| Ca: | at most 0.006, whereby |

the alloying level of the steel ST = 33.8C + 0.98Si + 1.15Mn + 0.47Cr + 2.32Mo + 0.85Ni + 0.47Cu + 1.16BL = 3.0 - 8.0, wherein BL = 0, if B ≤ 0.0005 and BL = 1, if B > 0.0008, and the composition of the steel meets the criterion

4. A steel as claimed in claim 3, characterised in that -177 + 9000C - 115000C2 + 750 Nb + 70Mo + 33Ni - 36Cr > 50.

5. A steel as claimed in claim 3, characterised in that -177 + 9000C - 115000C2 + 750 Nb + 70Mo + 33Ni - 36Cr > 100.

6. A steel as claimed in any one of preceding claims 3 to 5, char- acterised in that the carbon concentration of the steel is at least 0.03 wt %.

7. A steel as claimed in any one of the preceding claims 3 to 6, characterised in that the niobium concentration of the steel is 0.08-0.12 wt %.

8. A steel as claimed in any one of the preceding claims 3 to 7, characterised in that B ≤ 0.0005, N < 0.008 and 2 <Ti/N < 3.

9. A steel as claimed in any one of the preceding claims 3 to 7, characterised in that the steel is boron-free.

10. A steel as claimed in any one of the preceding claims 3 to 7, characterised in that Ti/N > 3.4 or Al/N > 8, if B > 0.0005.

11. A steel as claimed in any one of the preceding claims 3 to 10, characterised in that the reduction coefficient of its strength at 700°C is > 0.3 measured in a transient

test.

12. The use of a steel according to any one of the preceding claims 3 to 11 in applications

that require high strength at temperatures above 400°C.

13. The use of the steel according to claim 12 in building beams.

1. Verfahren zur Herstellung eines Stahlprodukts, welches Verfahren das Auswählen eines

niedriglegierten warmgewalzten oder normalisierten Stahls für Anwendungen, die hohen

Temperaturen ausgesetzt sind, umfasst, gekennzeichnet durch

Auswählen des C-, Si-, Mn-, Cr-, Mo-, Ni-, Cu- und B-Gehalts und der Abkühlgeschwindigkeit (CR) des Stahls nach dem Warmwalzen,

Berechnen der Streckgrenze des Stahls, der die ausgewählte Zusammensetzung hat, unter Verwendung der Formel

C die Kohlenstoffkonzentration des Stahls (Gew.-%) ist,

Si die Siliciumkonzentration des Stahls (Gew.-%) ist,

Mn die Mangankonzentration des Stahls (Gew.-%) ist,

Cr die Chromkonzentration des Stahls (Gew.-%) ist,

Mo die Molybdänkonzentration des Stahls (Gew.-%) ist,

Ni die Nickelkonzentration des Stahls (Gew.-%) ist,

Cu die Kupferkonzentration des Stahls (Gew.-%) ist, und

BL sich auf den Borgehalt des Stahls bezieht, und

BL = 0, wenn B ≤ 0,0005 und BL = 1, wenn B > 0,0008, wobei B die Borkonzentration des Stahls (Gew.-%) ist, und

CR sich auf die Abkühlgeschwindigkeit nach dem Warmwalzen (°C/s) bezieht, Vergleichen der berechneten Streckgrenze mit einem gewünschten Streckgrenzengrad, der für die Anwendung spezifiziert ist,

wenn die berechnete Streckgrenze den gewünschten Streckgrenzengrad erfüllt, Berechnen eines Verfestigungspotenzials LP95 für den Stahl, der die Zusammensetzung hat, unter Verwendung der Formel

wobei

Nb die Niobkonzentration des Stahls (Gew.-%) ist, und,

wenn das berechnete Verfestigungspotenzial LP95 > 0, der die Zusammensetzung aufweisende Stahl für die Verwendung in dieser Anwendung geeignet ist; und

wobei das Verfahren ferner die Herstellung des Stahlprodukts unter Verwendung der ausgewählten Zusammensetzung und der ausgewählten Abkühlgeschwindigkeit umfasst.

Auswählen des C-, Si-, Mn-, Cr-, Mo-, Ni-, Cu- und B-Gehalts und der Abkühlgeschwindigkeit (CR) des Stahls nach dem Warmwalzen,

Berechnen der Streckgrenze des Stahls, der die ausgewählte Zusammensetzung hat, unter Verwendung der Formel

C die Kohlenstoffkonzentration des Stahls (Gew.-%) ist,

Si die Siliciumkonzentration des Stahls (Gew.-%) ist,

Mn die Mangankonzentration des Stahls (Gew.-%) ist,

Cr die Chromkonzentration des Stahls (Gew.-%) ist,

Mo die Molybdänkonzentration des Stahls (Gew.-%) ist,

Ni die Nickelkonzentration des Stahls (Gew.-%) ist,

Cu die Kupferkonzentration des Stahls (Gew.-%) ist, und

BL sich auf den Borgehalt des Stahls bezieht, und

BL = 0, wenn B ≤ 0,0005 und BL = 1, wenn B > 0,0008, wobei B die Borkonzentration des Stahls (Gew.-%) ist, und

CR sich auf die Abkühlgeschwindigkeit nach dem Warmwalzen (°C/s) bezieht, Vergleichen der berechneten Streckgrenze mit einem gewünschten Streckgrenzengrad, der für die Anwendung spezifiziert ist,

wenn die berechnete Streckgrenze den gewünschten Streckgrenzengrad erfüllt, Berechnen eines Verfestigungspotenzials LP95 für den Stahl, der die Zusammensetzung hat, unter Verwendung der Formel

wobei

Nb die Niobkonzentration des Stahls (Gew.-%) ist, und,

wenn das berechnete Verfestigungspotenzial LP95 > 0, der die Zusammensetzung aufweisende Stahl für die Verwendung in dieser Anwendung geeignet ist; und

wobei das Verfahren ferner die Herstellung des Stahlprodukts unter Verwendung der ausgewählten Zusammensetzung und der ausgewählten Abkühlgeschwindigkeit umfasst.

2. Verfahren nach Anspruch 1, dadurch gekennzeichnet, dass die Zusammensetzung des Stahls so ausgewählt wird, dass seine Zusammensetzung in

Gewichtsprozent beträgt:

die Konzentrationen von Mangan und Molybdän so gewählt sind, dass Mn > 1,6 oder Mo

< 0,1, wenn B > 0,0005, und

das Legierungsniveau des Stahls ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL, so dass sein Wert 3,0-8,0 beträgt, wobei BL = 0, wenn B ≤ 0,0005 und BL = 1, wenn B > 0,0008.

| C: | 0,01-0,05 |

| Si: | höchstens 0,7 |

| Mn: | 1,0-2,3 |

| Ni: | höchstens 1,5 |

| Cr: | höchstens 1,5 |

| Mo: | höchstens 0,7 |

| Cu: | höchstens 0,3 |

| Nb: | 0,04-0,15 |

| B: | höchstens 0,004 |

| N: | höchstens 0,01 |

| Al: | höchstens 0,1 |

| V: | höchstens 0,02 |

| Ti: | höchstens 0,05 |

| Ca: | höchstens 0,006, wobei |

das Legierungsniveau des Stahls ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL, so dass sein Wert 3,0-8,0 beträgt, wobei BL = 0, wenn B ≤ 0,0005 und BL = 1, wenn B > 0,0008.

3. Niedriglegierter warmgewalzter oder normalisierten Stahl zur Verwendung bei Anwendungen,

die Hochtemperaturfestigkeit und Wärmebeständigkeit erfordern, wobei der Kohlenstoffgehalt

des Stahls > 0,01 Gew.-% beträgt, dadurch gekennzeichnet, dass die Zusammensetzung des Stahls in Gewichtsprozent wie folgt ist:

Mn > 1,6 oder Mo < 0,1, wenn B > 0,0005, und

das Legierungsniveau des Stahls ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL, = 3,0-8,0 beträgt, wobei BL = 0, wenn B ≤ 0,0005 und BL = 1, wenn B > 0,0008, und die Zusammensetzung des Stahls das Kriterium

erfüllt.

| C: | über 0,01 und höchstens 0,05 |

| Si: | höchstens 0,7 |

| Mn: | 1,0-2,3 |

| Ni: | höchstens 1,5 |

| Cr: | höchstens 1,5 |

| Mo: | < 0,4 |

| Cu: | höchstens 0,3 |

| Nb: | 0,04-0,15 |

| B: | höchstens 0,004 |

| N: | höchstens 0,01 |

| Al: | höchstens 0,1 |

| V: | höchstens 0,02 |

| Ti: | höchstens 0,05 |

| Ca: | höchstens 0,006, wobei |

das Legierungsniveau des Stahls ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL, = 3,0-8,0 beträgt, wobei BL = 0, wenn B ≤ 0,0005 und BL = 1, wenn B > 0,0008, und die Zusammensetzung des Stahls das Kriterium

erfüllt.

4. Stahl nach Anspruch 3, dadurch gekennzeichnet, dass -177 + 9000C - 115.000C2 + 750Nb + 71Mo + 33Ni - 36Cr > 50.

5. Stahl nach Anspruch 3, dadurch gekennzeichnet, dass -177 + 9000C - 115.000C2 + 750Nb + 71Mo + 33Ni - 36Cr > 100.

6. Stahl nach einem der vorhergehenden Ansprüche 3-5, dadurch gekennzeichnet, dass die Kohlenstoffkonzentration des Stahls 0,03 Gew.-% beträgt.

7. Stahl nach einem der vorhergehenden Ansprüche 3-6, dadurch gekennzeichnet, dass die Niobkonzentration des Stahls mindestens 0,08-0,12 Gew.-% beträgt.

8. Stahl nach einem der vorhergehenden Ansprüche 3-7, dadurch gekennzeichnet, dass B ≤ 0,0005, N < 0,008 und 2 < Ti/N < 3.

9. Stahl nach einem der vorhergehenden Ansprüche 3-7, dadurch gekennzeichnet, dass der Stahl frei von Bor ist.

10. Stahl nach einem der vorhergehenden Ansprüche 3-7, dadurch gekennzeichnet, dass Ti/N > 3,4 oder Al/N > 8 wenn B > 0,0005.

11. Stahl nach einem der vorhergehenden Ansprüche 3-10, dadurch gekennzeichnet, dass der Reduzierungskoeffizient seiner Festigkeit bei 700 °C, gemessen in einer transienten

Prüfung, > 0,3 ist.

12. Verwendung eines Stahls nach einem der vorhergehenden Ansprüche 3-11 in Anwendungen,

die eine hohe Festigkeit bei Temperaturen über 400 °C erfordern.

13. Verwendung des Stahls nach Anspruch 12 in Bauwerksträgern.

1. Procédé de fabrication d'un produit en acier, le procédé comprenant la sélection d'un

acier de faible alliage laminé à chaud ou normalisé pour des applications exposées

à des températures élevées, caractérisé par

la sélection du niveau de C, Si, Mn, Cr, Mo, Ni, Cu et B et de la vitesse de refroidissement (CR) de l'acier après le laminage à chaud,

le calcul de la limite d'élasticité de l'acier ayant la composition sélectionnée à l'aide de la formule

C est la concentration en carbone de l'acier (% en poids),

Si est la concentration en silicium de l'acier (% en poids),

Mn est la concentration en manganèse de l'acier (% en poids), Cr est la concentration en chrome de l'acier (% en poids),

Mo est la concentration en molybdène de l'acier (% en poids), Ni est la concentration en nickel de l'acier (% en poids),

Cu est la concentration en cuivre de l'acier (% en poids), et BL fait référence au niveau de bore de l'acier, et

BL = 0, si B ≤ 0,0005 et BL = 1, si B > 0,0008, où B est la concentration en bore de l'acier (% en poids), et

CR fait référence à la vitesse de refroidissement après un laminage à chaud (°C/s),

la comparaison de la limite d'élasticité calculée avec un degré de limite d'élasticité souhaité spécifié pour l'application,

si la limite d'élasticité calculée satisfait au niveau de limite d'élasticité souhaité, le calcul pour l'acier ayant ladite composition d'un potentiel de renforcement, LP95, à l'aide de la formule

dans laquelle Nb est la concentration en niobium de l'acier (% en poids), et

si le potentiel de renforcement calculé LP95 > 0, l'acier ayant ladite composition est approprié pour être utilisé dans l'application ; et

le procédé comprenant en outre la fabrication du produit en acier à l'aide de la composition sélectionnée et de la vitesse de refroidissement sélectionnée.

la sélection du niveau de C, Si, Mn, Cr, Mo, Ni, Cu et B et de la vitesse de refroidissement (CR) de l'acier après le laminage à chaud,

le calcul de la limite d'élasticité de l'acier ayant la composition sélectionnée à l'aide de la formule

C est la concentration en carbone de l'acier (% en poids),

Si est la concentration en silicium de l'acier (% en poids),

Mn est la concentration en manganèse de l'acier (% en poids), Cr est la concentration en chrome de l'acier (% en poids),

Mo est la concentration en molybdène de l'acier (% en poids), Ni est la concentration en nickel de l'acier (% en poids),

Cu est la concentration en cuivre de l'acier (% en poids), et BL fait référence au niveau de bore de l'acier, et

BL = 0, si B ≤ 0,0005 et BL = 1, si B > 0,0008, où B est la concentration en bore de l'acier (% en poids), et

CR fait référence à la vitesse de refroidissement après un laminage à chaud (°C/s),

la comparaison de la limite d'élasticité calculée avec un degré de limite d'élasticité souhaité spécifié pour l'application,

si la limite d'élasticité calculée satisfait au niveau de limite d'élasticité souhaité, le calcul pour l'acier ayant ladite composition d'un potentiel de renforcement, LP95, à l'aide de la formule

dans laquelle Nb est la concentration en niobium de l'acier (% en poids), et

si le potentiel de renforcement calculé LP95 > 0, l'acier ayant ladite composition est approprié pour être utilisé dans l'application ; et

le procédé comprenant en outre la fabrication du produit en acier à l'aide de la composition sélectionnée et de la vitesse de refroidissement sélectionnée.

2. Procédé selon la revendication 1, caractérisé en ce que la composition de l'acier est sélectionnée de sorte que sa composition en pourcentage

en poids est :

les concentrations en manganèse et molybdène sont sélectionnées de sorte que Mn >

1,6 ou Mo < 0,1, si B > 0,0005, et

le niveau d'alliage de l'acier ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL de sorte que sa valeur est 3,0-8,0,

où BL = 0, si B ≤ 0,0005 et BL = 1, si B > 0,0008.

| C : | 0,01-0,05 |

| Si : | au plus 0,7 |

| Mn : | 1,0-2,3 |

| Ni : | au plus 1,5 |

| Cr : | au plus 1,5 |

| Mo : | au plus 0,7 |

| Cu : | au plus 0,3 |

| Nb : | 0,04-0,15 |

| B : | au plus 0,004 |

| N : | au plus 0,01 |

| Al : | au plus 0,1 |

| V : | au plus 0,02 |

| Ti : | au plus 0,05 |

| Ca : | au plus 0,006, moyennant quoi |

le niveau d'alliage de l'acier ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL de sorte que sa valeur est 3,0-8,0,

où BL = 0, si B ≤ 0,0005 et BL = 1, si B > 0,0008.

3. Acier de faible alliage laminé à chaud ou normalisé à utiliser dans des applications

nécessitant l'endurance à des températures élevées et la résistance à la chaleur,

la concentration en carbone de l'acier étant > 0,01 % en poids, caractérisé en ce que la composition de l'acier en pourcentage en poids est la suivante :

Mn > 1,6 ou Mo < 0,1, si B > 0,0005, et

le niveau d'alliage de l'acier ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL = 3,0-8,0, où BL = 0, si B ≤ 0,0005 et BL = 1, si B > 0,0008, et la composition de l'acier remplit le critère

| C : | supérieure à 0,01 et au plus 0,05 |

| Si : | au plus 0,7 |

| Mn : | 1,0-2,3 |

| Ni : | au plus 1,5 |

| Cr : | au plus 1,5 |

| Mo : | < 0,4 |

| Cu : | au plus 0,3 |

| Nb : | 0,04-0,15 |

| B : | au plus 0,004 |

| N : | au plus 0,01 |

| Al : | au plus 0,1 |

| V : | au plus 0,02 |

| Ti : | au plus 0,05 |

| Ca : | au plus 0,006, moyennant quoi |

le niveau d'alliage de l'acier ST = 33,8C + 0,98Si + 1,15Mn + 0,47Cr + 2,32Mo + 0,85Ni + 0,47Cu + 1,16BL = 3,0-8,0, où BL = 0, si B ≤ 0,0005 et BL = 1, si B > 0,0008, et la composition de l'acier remplit le critère

4. Acier selon la revendication 3, caractérisé en ce que -177 + 9000C - 115000C2 + 750Nb + 71 Mo + 33Ni - 36Cr > 50.

5. Acier selon la revendication 3, caractérisé en ce que -177 + 9000C - 115000C2 + 750Nb + 71 Mo + 33Ni - 36Cr > 100.

6. Acier selon l'une quelconque des revendications précédentes 3 à 5, caractérisé en ce que la concentration en carbone de l'acier est d'au moins 0,03 % en poids.

7. Acier selon l'une quelconque des revendications précédentes 3 à 6, caractérisé en ce que la concentration en niobium de l'acier est de 0,08-0,12 % en poids.

8. Acier selon l'une quelconque des revendications précédentes 3 à 7, caractérisé en ce que B ≤ 0,0005, N < 0,008 et 2 < Ti/N < 3.

9. Acier selon l'une quelconque des revendications précédentes 3 à 7, caractérisé en ce que l'acier est dépourvu de bore.

10. Acier selon l'une quelconque des revendications précédentes 3 à 7, caractérisé en ce que Ti/N > 3,4 ou Al/N > 8, si B > 0,0005.

11. Acier selon l'une quelconque des revendications précédentes 3 à 10, caractérisé en ce que le coefficient de réduction de sa résistance à 700°C est > 0,3, mesuré lors d'un

essai transitoire.

12. Utilisation d'un acier selon l'une quelconque des revendications précédentes 3 à 11

dans des applications qui nécessitent une résistance élevée à des températures supérieures

à 400°C.

13. Utilisation de l'acier selon la revendication 12 dans la construction de poutres.

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the reader's convenience only. It does not form part of the European patent document. Even though great care has been taken in compiling the references, errors or omissions cannot be excluded and the EPO disclaims all liability in this regard.

Patent documents cited in the description

- JP2004339549B [0006]

- JP2002173733B [0007]

- JP2006241552B [0008]

- US20060063335A1 [0009]

- WO2006093282A [0010]