|

(11) | EP 3 178 910 B1 |

| (12) | EUROPEAN PATENT SPECIFICATION |

|

|

| (54) |

GREASE COMPOSITION SCHMIERFETTZUSAMMENSETZUNG COMPOSITION DE GRAISSE |

|

|

|||||||||||||||||||||||||||||||

| Note: Within nine months from the publication of the mention of the grant of the European patent, any person may give notice to the European Patent Office of opposition to the European patent granted. Notice of opposition shall be filed in a written reasoned statement. It shall not be deemed to have been filed until the opposition fee has been paid. (Art. 99(1) European Patent Convention). |

[0002] Grease is typically used for sliding surfaces where moving contact surfaces make it difficult to keep a lubricant film adhered to the lubricated surfaces, for example, such as in sliding portions and rotors of mechanisms. In recent years, there is an increasing trend of smaller, lighter, higher-output, and longer-life devices along with the advancement of machine technology in products such as automobiles and electrical devices, and these products are used under ever demanding operating conditions. This has created a demand for higher performance in the lubricity or other properties of greases used in devices.

[0003] In order to improve the lubricity of grease, it has been proposed to select a base oil, a thickener, and additives. For example, it is known to add a specific phosphite ester (PTL 1), or incorporate organic molybdenum, zinc dithiophosphate, a polysulfide, and a triglyceride (PTL 2). Further, US 4 029 587 A discloses lubricants and functional fluids containing substituted sulfolanes as seal swelling agents. WO 2006/023317 A1 discloses lubricant compositions containing a combination of conditioning agents for preserving the integrity of elastomeric materials, which include a swell agent such as a sulfolane.

[0004] However, for further improvement of lubricity, there is a need for development of a novel additive for grease.

[0006] The present invention has been made to provide a solution to the foregoing problem, and is intended to provide a grease composition of excellent lubricity containing a novel additive for grease.

[0007] The present inventors conducted intensive studies to develop a grease composition of excellent lubricity, and found, rather by chance, that a specific sulfolane derivative is effective as an additive for grease. It was confirmed that the sulfolane derivative has synergy with other additives under specific conditions.

[0008] The present invention is based on these findings, and includes the following.

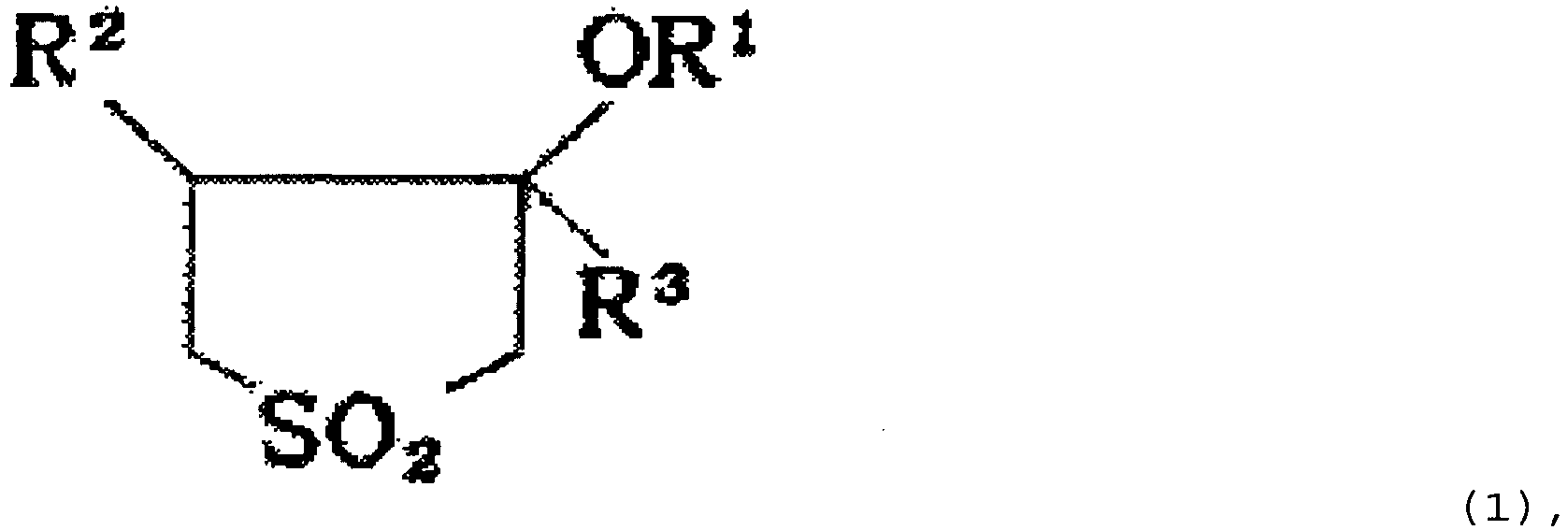

- [1] A grease composition comprising a lubricant base oil, a thickener, at least one

of diphenyl hydrogen phosphite and tricresyl phosphate in an amount of 0.1 to 10 mass%

with respect to the total amount of the grease composition, and a sulfolane derivative

represented by the following general formula (1).

In the formula, R1 represents a hydrocarbon group of 1 to 20 carbon atoms, and R2 and R3 each represent hydrogen, or a hydrocarbon group of 1 to 20 carbon atoms. - [2] The grease composition according to [1], wherein the sulfolane derivative of the general formula (1) is one in which R1 is an alkyl group of 4 to 18 carbon atoms, and R2 and R3 are each hydrogen, or a hydrocarbon group of 1 to 8 carbon atoms.

- [3] The grease composition according to above-described [1] or [2], wherein the sulfolane derivative is contained in a content of 0.2 to 10 mass%.

[0009] The grease composition of the present invention has distinguishing effects including a low coefficient of friction, high load bearing characteristics, and excellent lubricity.

Lubricant Base Oil

[0010] A lubricant base oil of the present invention may be any of a mineral oil, a synthetic oil, an animal and vegetable oil, or a mixture thereof, provided that it is a lubricant base oil for common lubricants.

[0011] The lubricant base oil has a kinetic viscosity at 100°C of preferably 1 to 200 mm2/s, more preferably 5 to 50 mm2/s.

[0012] The content of the lubricant base oil is preferably 50 mass% or more, more preferably 60 mass% or more with respect to the total amount of the grease composition. Typically, the upper limit of the content is preferably 95 mass% or less, more preferably 85 mass% or less, accounting for the balance.

[0013] Mineral oil-type base oils for lubricant are generally prepared by distilling crude oil under atmospheric pressure, optionally further distilling the atmospheric residual oil under reduced pressure, refining the resulting distillate oil by various refining processes to obtain a lubricating oil fraction. The fraction is used as a base oil, as it is, or a base oil is prepared by blending various additives to the fraction. Examples of the above refining processes include hydrotreating, solvent extraction, solvent dewaxing, hydrodewaxing, sulfuric acid washing, and a clay treatment. A mineral oil-type base oil for lubricant suitable for the present invention can be obtained by combining these processes in an appropriate order and submitting thereto. A mixture of two or more refined oils having different properties obtained by processing different crude oils or different distillate oils in combination with different processes, or in different orders may also be used as a suitable base oil.

[0014] For safety of handling, the mineral oil-type base oil for lubricant is preferably one with an aromatic content of 20% or less.

[0015] Examples of the synthetic oil-type base oil for lubricant include poly α-olefin (PAO), a low-molecular copolymer of ethylene and α-olefin, high-molecular polymers such as polybutene and polyisobutene, oxygen-containing synthetic oils such as ester oils and ether oils, silicone oils, fluorinated oils, and alkylnaphthalene. These may be used either alone or in combination.

[0016] Preferred examples of the animal and vegetable oil-type base oils for lubricant include milkfat, beef tallow, lard (pig fat), mutton tallow, whale oil, salmon oil, bonito oil, herring oil, cod oil, soy oil, canola oil, sunflower oil, safflower oil, peanut oil, corn oil, cottonseed oil, rice bran oil, sesame oil, olive oil, linseed oil, castor oil, cacao butter, palm oil, coconut oil, hempseed oil, rice oil, and tea seed oil.

Thickener

[0017] The thickener used in the present invention may be, for example, a metal soap- or urea-based thickener commonly used for grease compositions, or an organic synthetic resin powder, an inorganic powder, a gelatinizer made from an amide compound, or a wax.

[0018] The metal soap-based thickener is a metal carboxylate (metal soap), and may be, for example, a sodium soap, a calcium soap, an aluminum soap, or a lithium soap, of which the lithium soap is preferred.

[0019] Examples of the carboxylic acids that form the soap include fatty acids, and aliphatic divalent carboxylic acids. The metal soap may be a so-called composite metal soap.

[0020] Examples of the urea-based thickener include urea compounds such as diurea compounds, triurea compounds, tetraurea compounds, polyurea compounds (excluding diurea compounds, triurea compounds, and tetraurea compounds), urethane compounds such as urea-urethane compounds, and diurethane, and mixtures thereof. Preferred are diurea compounds, urea-urethane compounds, diurethane compounds, and mixtures thereof.

[0021] Examples of the organic synthetic resin powder include fluororesin particles (particularly, polytetrafluoroethylene resin particles).

[0022] Examples of the inorganic powder include metal oxide such as silica, metal carbonates such as calcium carbonate, metal sulfates such as calcium sulfate, and nitrides such as h-BN (atmospheric-phase boron nitride) . The inorganic powder also may be, for example, a mineral-derived metal oxide such as bentonite.

[0023] Examples of the gelatinizer made from amide compounds include monoamides, bisamides, and triamides. Preferred are aliphatic monoamides, and aliphatic bisamides.

[0025] The thickener content is preferably 3 to 45 mass%, more preferably 5 to 30 mass% with respect to the total amount of the grease composition.

Sulfolane Derivative

[0026] The sulfolane derivative of the present invention is a compound represented by the following general formula (1).

In the formula, R1 represents a hydrocarbon group of 1 to 20 carbon atoms, and R2 and R3 each represent hydrogen, or a hydrocarbon group of 1 to 20 carbon atoms.

[0027] The sulfolane derivative is preferably one in which R1 in the general formula (1) is an alkyl group of 4 to 18 carbon atoms, more preferably one in which R1 is an alkyl group of 6 to 16 carbon atoms, and R2 and R3 are each hydrogen or a hydrocarbon group of 1 to 8 carbon atoms. More preferably, R2 and R3 are both hydrogens.

[0028] The sulfolane compound is commercially available as a seal-swell agent, and may be produced by, for example, the method described in JP-A-2006-206580.

[0029] The content of the sulfolane derivative is preferably 0.2 to 10 mass%, more preferably 0.5 to 5 mass% with respect to the total amount of the grease composition.

Second Additive

[0030] In the present invention, a second additive, which is at least one compound selected from a diphenyl hydrogen phosphite and tricresyl phosphate, is added in addition to the lubricant base oil, the thickener, and the sulfolane derivative.

[0031] The content of the second additive is 0.1 to 10 mass%, preferably 0.2 to 5 mass% with respect to the total amount of the grease composition. The content of the phosphorus element is preferably 0.01 to 1 mass%, more preferably 0.02 to 0.5 mass% with respect to the total amount of the grease composition.

Other Additives

[0032] The grease composition of the present invention may also contain known additives, other than the second additive. Examples of such additives include phenol- or amine-based antioxidants; anti-rusting agents such as carboxylates, and sulfonates; antiwear agents such as polyalkylene glycol, and glycerine; extreme-pressure agents such as chlorinated paraffins; oiliness improvers such as higher fatty acids, and synthetic esters; and solid lubricants such as graphite, and molybdenum disulfide. These may be added either alone or in a combination of two or more.

Preparation and Properties of Grease

[0033] The grease composition of the present invention may be prepared by using a common grease preparation method, specifically by blending the thickener with the lubricant base oil to produce a base grease, and blending and mixing the additives to the base grease. Alternatively, the grease composition of the present invention may be prepared by blending and mixing the lubricant base oil, the thickener, and the additives at once.

[0034] The grease composition of the present invention is semi-solid or solid at room temperature, and has a consistency of 000 to 6 in terms of a JIS K2220 consistency number.

Examples

[0035] The thickener shown in Table 1 was added to the lubricant base oil, and the additives were added to make the compositions shown in Table 1. The mixture was stirred, and passed through a roller mill to obtain grease compositions of Examples, Reference Examples and Comparative Examples.

[0037] "Mineral oil 1" is a highly-refined mineral oil (kinetic viscosity at 40°C: 38 mm2/s) obtained through hydrocracking of a crude oil-derived component.

[0038] "Mineral oil 2" is a solvent-refining paraffinic mineral oil (kinetic viscosity at 40°C: 100 mm2/s).

[0039] "Urea" in "Thickener" is a urea-based thickener obtained through reaction of diphenylmethane-4,4'-diisocyanate (MDI) and monoamine which is a mixture of 2 mole parts of p-toluidine and 8 mole parts of cyclohexylamine.

[0044] "Sulfolane derivative" is a compound of the general formula (1) in which R1 is an alkyl group of 8 carbon atoms, and R2 and R3 are hydrogens.

[0045] ZnDTP (zinc dithiophosphate) have alkyl group of 6 carbon atoms, and a Zn element content of 8.7 mass%.

[0046] MoDTC (molybdenum dithiocarbamate) have alkyl group of 4-12 carbon atoms, and a Mo element content of 10.0 mass%.

[0047] The friction characteristics were determined by conducting a ball/disc SRV test, in which the grease composition was subjected to friction for 5 min at a frequency of 50 Hz, an amplitude of 1.0 mm, and a temperature of 40°C under a load of 50 N using a 10-mm ball. The friction test was continued for the next 5 min under an increased load of 100 N, and for another 5 min under 200 N. Subsequently, the load was increased in an increment of 100 N, and the coefficient of friction was measured for each load until 600 N.

[0048] The load at which the coefficient of friction showed an abrupt increase to 0.3 or higher, and a burn occurred was measured as the burn load (load bearing characteristics) . The burn load was measured to be 600 N or higher when burns did not occur under 600 N.

[0049] The coefficient of friction under 50 N was determined as a measure of friction characteristics because the friction characteristics under a light load are important for saving energy in an actual use environment such as in bearings.

[0052] As is clear from these results, the grease compositions with the addition of the sulfolane derivative had greatly improved load bearing characteristics compared to the traditional grease compositions that contained a phosphite ester or a phosphate ester.

[Table 1]

| Exa.1 | Exa.2 | Exa.3 | Exa.4 | Exa.5 | Exa.6 | Exa.7 | Exa.8 | Exa.9 | Exa.10 | C.Exa.1 | C.Exa.2 | C.Exa.3 | ||

| Base Oil | PAO | 83 | 83 | 80 | 82 | 82 | 82 | 82 | 82 | 85 | 83 | 83 | ||

| Mineral oil 1 | 83 | |||||||||||||

| Mineral oil 2 | 83 | |||||||||||||

| Thickener | Urea | 15 | 15 | 15 | ||||||||||

| Li soap | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 | ||||

| Additives | Sulfolane derivative | 2 | 2 | 2 | 2 | 5 | 2 | 2 | 2 | 2 | 2 | |||

| Phosphite ester | 1 | 2 | ||||||||||||

| Phosphate ester | 1 | 2 | ||||||||||||

| Polysulfide | 1 | |||||||||||||

| ZnDTP | 1 | |||||||||||||

| MoDTC | 1 | |||||||||||||

| Consistency | 300 | 300 | 300 | 300 | 310 | 305 | 305 | 305 | 305 | 305 | 295 | 300 | 300 | |

| SRV lubrication test | Burn load (N) | 600 or higter | 601 or higter | 602 or higter | 603 or higter | 604 or higter | 605 or higter | 606 or higter | 607 or higter | 608 or higter | 609 or higter | 100 | 500 | 500 |

| Coefficient of friction | 0.16 | 0.16 | 0.16 | 0.16 | 0.17 | 0.14 | 0.15 | 0.16 | 0.16 | 0.16 | 0.17 | 0.15 | 0.17 | |

[0054] The grease composition of the present invention has a small coefficient of friction, and high load bearing characteristics, and excels in lubricity. The grease composition of the present invention has use as a lubricant for, for example, sliding portions or rotors of automobiles and electrical devices.

1. A grease composition comprising a lubricant base oil, a thickener, at least one of

diphenyl hydrogen phosphite and tricresyl phosphate in an amount of 0.1 to 10 mass%

with respect to the total amount of the grease composition, and a sulfolane derivative

represented by the following general formula (1)

wherein R1 represents a hydrocarbon group of 1 to 20 carbon atoms, and R2 and R3 each represent hydrogen, or a hydrocarbon group of 1 to 20 carbon atoms.

wherein R1 represents a hydrocarbon group of 1 to 20 carbon atoms, and R2 and R3 each represent hydrogen, or a hydrocarbon group of 1 to 20 carbon atoms.

2. The grease composition according to claim 1, wherein the sulfolane derivative of the

general formula (1) is one in which R1 is an alkyl group of 4 to 18 carbon atoms, and R2 and R3 are each hydrogen, or a hydrocarbon group of 1 to 8 carbon atoms.

3. The grease composition according to claim 1 or 2, wherein the sulfolane derivative

is contained in a content of 0.2 to 10 mass%.

1. Schmiermittelzusammensetzung, umfassend ein Schmierstoff-Basisöl, ein Verdickungsmittel,

mindestens eines von Diphenylhydrogenphosphit und Tricresylphosphat in einer Menge

von 0,1 bis 10 Masse-% bezüglich der Gesamtmenge der Schmiermittelzusammensetzung,

und ein Sulfolanderivat, dargestellt durch die folgende allgemeine Formel (1)

worin R1 eine Kohlenwasserstoffgruppe mit 1 bis 20 Kohlenstoffatomen darstellt und R2 und R3 jeweils Wasserstoff oder eine Kohlenwasserstoffgruppe mit 1 bis 20 Kohlenstoffatomen darstellen.

worin R1 eine Kohlenwasserstoffgruppe mit 1 bis 20 Kohlenstoffatomen darstellt und R2 und R3 jeweils Wasserstoff oder eine Kohlenwasserstoffgruppe mit 1 bis 20 Kohlenstoffatomen darstellen.

2. Schmiermittelzusammensetzung gemäß Anspruch 1, wobei das Sulfolanderivat der allgemeinen

Formel (1) eines ist, worin R1 eine Alkylgruppe mit 4 bis 18 Kohlenstoffatomen ist und R2 und R3 jeweils Wasserstoff oder eine Kohlenwasserstoffgruppe mit 1 bis 8 Kohlenstoffatomen

sind.

3. Schmiermittelzusammensetzung gemäß Anspruch 1 oder 2, wobei das Sulfolanderivat in

einem Anteil von 0,2 bis 10 Masse-% enthalten ist.

1. Composition de graisse comprenant une huile de base lubrifiante, un épaississant,

au moins l'un parmi de l'hydrogénophosphite de diphényle et du phosphate de tricrésyle

en une quantité allant de 0,1 à 10% en masse par rapport à la quantité totale de la

composition de graisse, et un dérivé de sulfolane représenté par la formule générale

(1) suivante :

où R1 représente un groupe hydrocarboné ayant 1 à 20 atomes de carbone, et R2 et R3 représentent chacun, de l'hydrogène ou un groupe hydrocarboné ayant 1 à 20 atomes de carbone.

où R1 représente un groupe hydrocarboné ayant 1 à 20 atomes de carbone, et R2 et R3 représentent chacun, de l'hydrogène ou un groupe hydrocarboné ayant 1 à 20 atomes de carbone.

2. Composition de graisse selon la revendication 1, où le dérivé de sulfolane de la formule

générale (1) est celui dans lequel R1 est un groupe alkyle ayant 4 à 18 atomes de carbone et R2 et R3 sont chacun, de l'hydrogène ou un groupe hydrocarboné ayant 1 à 8 atomes de carbone.

3. Composition de graisse selon la revendication 1 ou 2, où le dérivé de sulfolane est

présent en une quantité allant de 0,2 à 10% en masse.

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the reader's convenience only. It does not form part of the European patent document. Even though great care has been taken in compiling the references, errors or omissions cannot be excluded and the EPO disclaims all liability in this regard.

Patent documents cited in the description

- US4029587A [0003]

- WO2006023317A1 [0003]

- JP2012057134A [0005]

- JP2014043526A [0005]

- JP2006206580A [0028]