(57) The filaments of a false twisted multifilament textile yarn (14) are intermingled

to increase their cohesion, and the residual torque in the yarn (14) is reduced, by

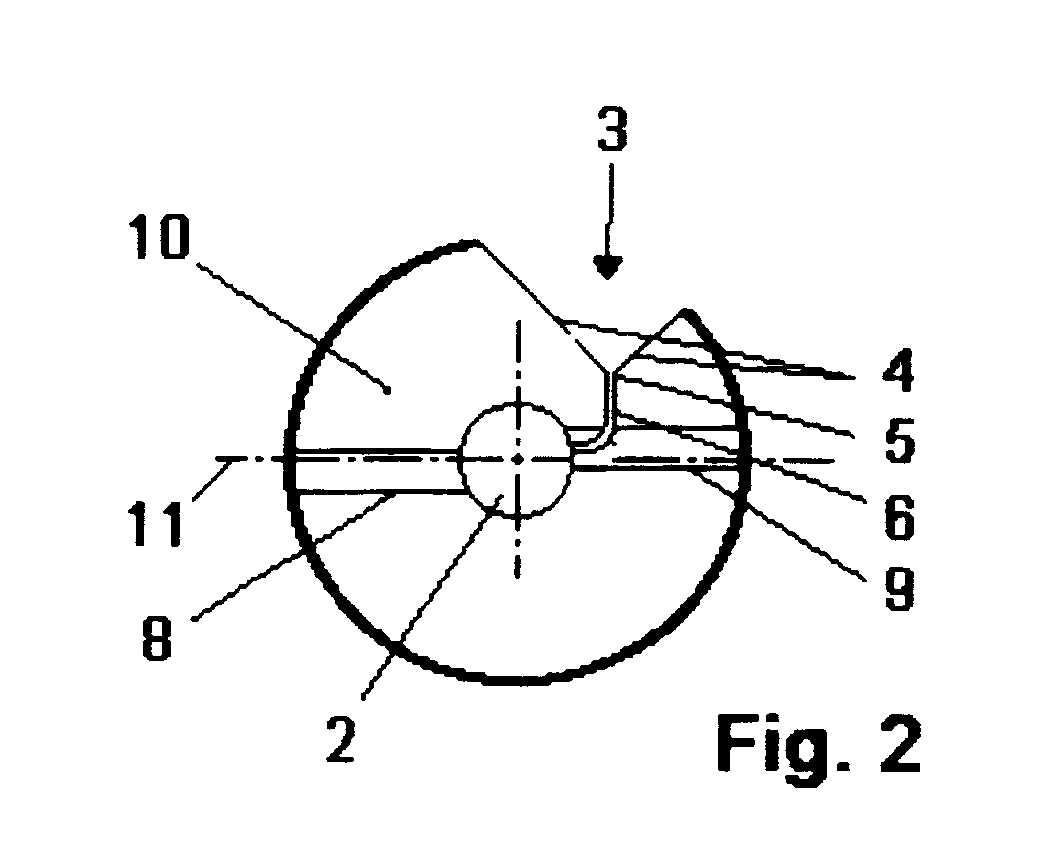

forwarding the yarn (14) along a yarn path (11) through a duct (2, 13) in a nozzle

body (10, 12), and directing a fluid flow (8, 9, 18) into the duct (2) transversely

of the yarn path (11) with the yarn path (11) centrally disposed relative to the fluid

flow (8, 9, 18) to intermingle the filaments and simultaneously directing the fluid

flow (8, 9) to swirl around the yam path (11) to reduce the residual torque. This

is achieved by directing two fluid flows (8,9) in opposed, overlapping directions

but offset relative to each other, or by directing the fluid flow (18) towards a base

surface (17) of the duct (13) which is planar and inclined laterally of the duct (13)

out of the perpendicular (21) to the direction (20) of fluid flow (18). A yarn threading

slot (6, 22) extends longitudinally of the body (10, 12) and communicates with the

duct (2, 13) and the exterior of the body (10, 12). The slot (6, 22) has a curved

profile between the duct (2, 13) and an enlarged inlet (3, 24) at the exterior of

the body (10, 12).

|

|